Method and system for detecting nozzle and electrode wear

A technology of electrodes and nozzles, which is applied in the system field of nozzles and electrodes loss, can solve problems such as waste, low efficiency, waste of additional costs, etc., and achieve the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will now be described in more detail with reference to the accompanying drawings. A preferred embodiment is shown in the drawing. The present invention, however, is capable of many embodiments and is therefore not to be considered limited to the examples given herein; the purpose of these examples is only to make the description of the invention more complete and complete and to inform the scope of the invention Those skilled in the art. Throughout the drawings, the same reference numerals refer to the same parts.

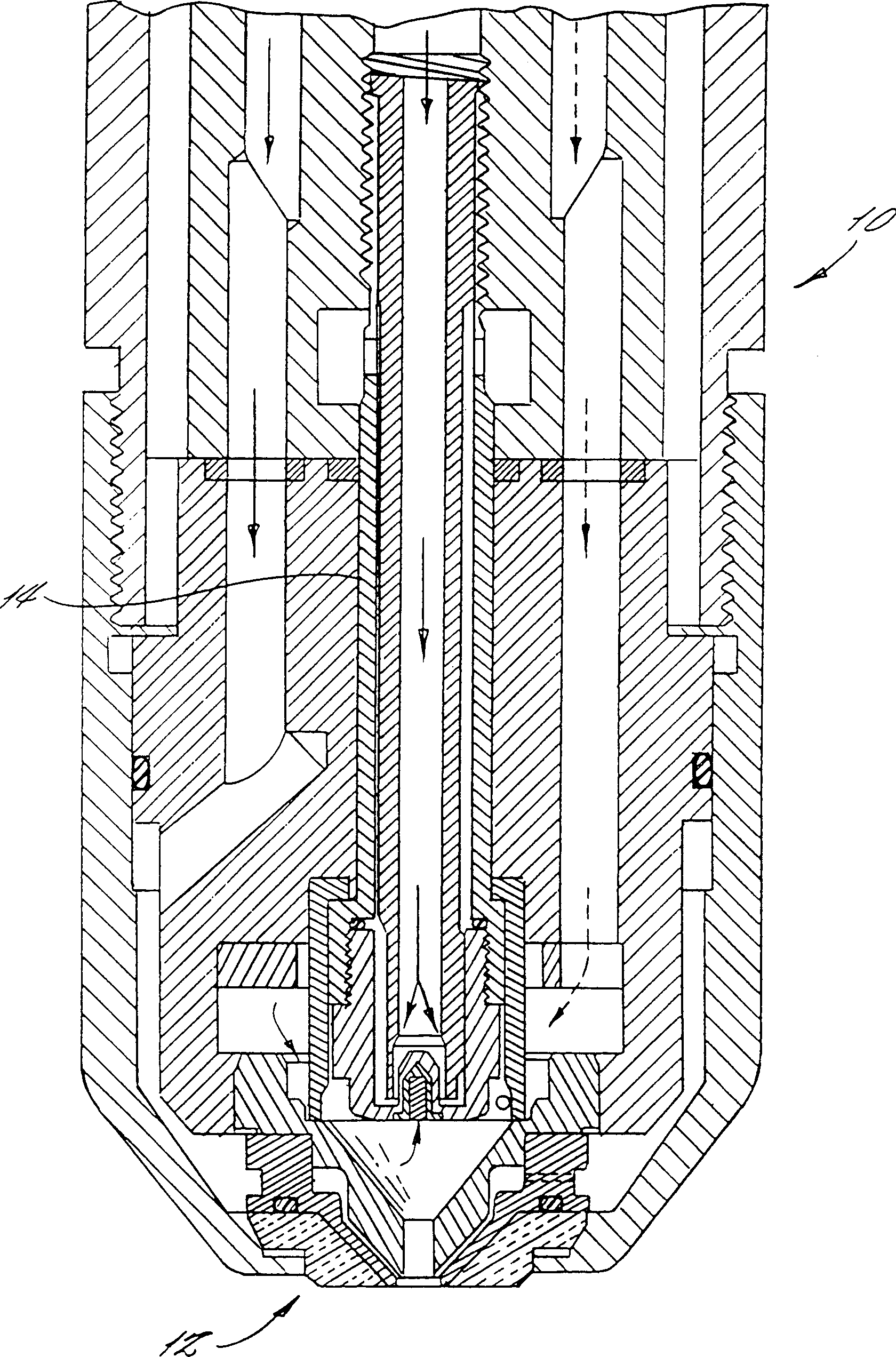

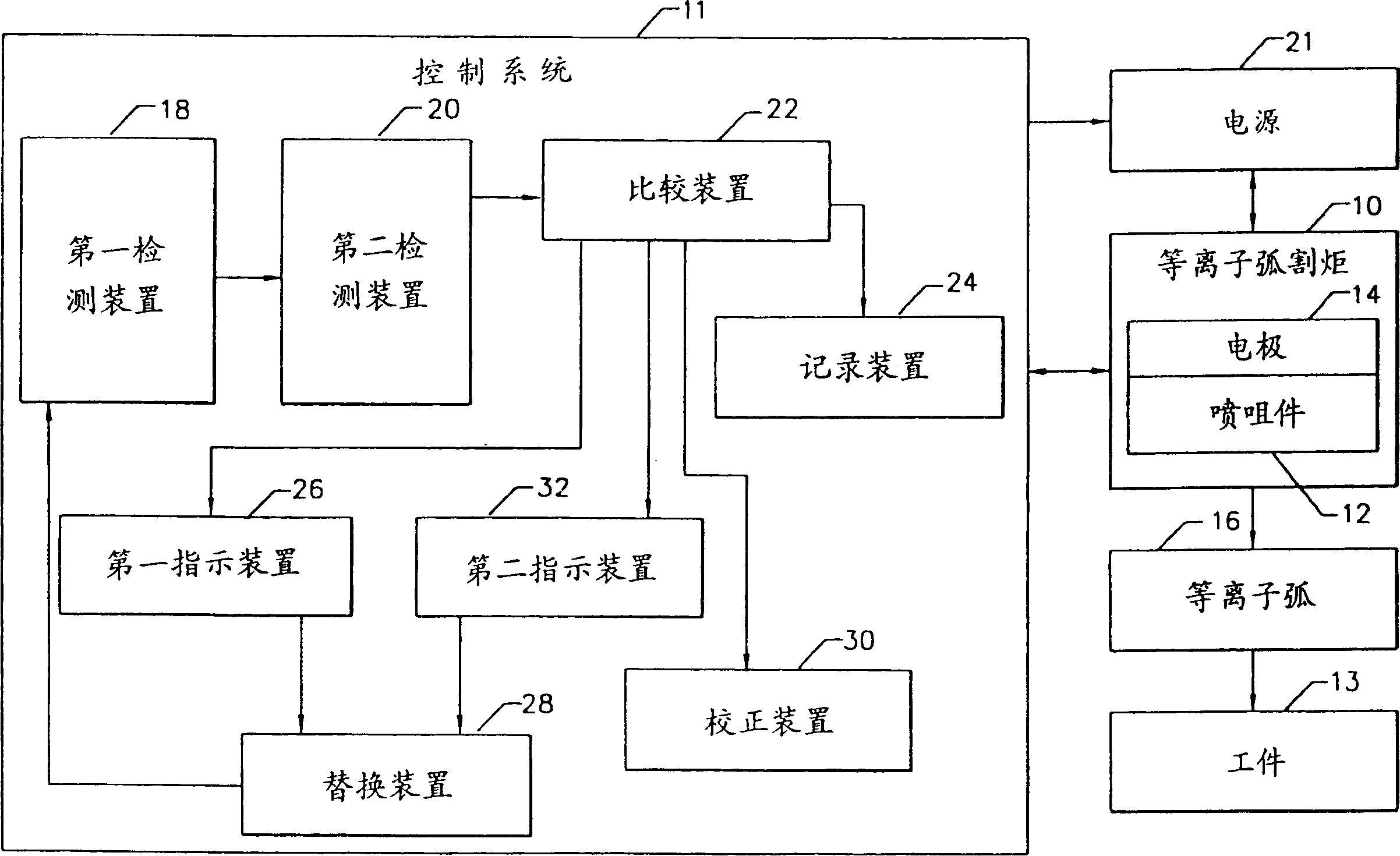

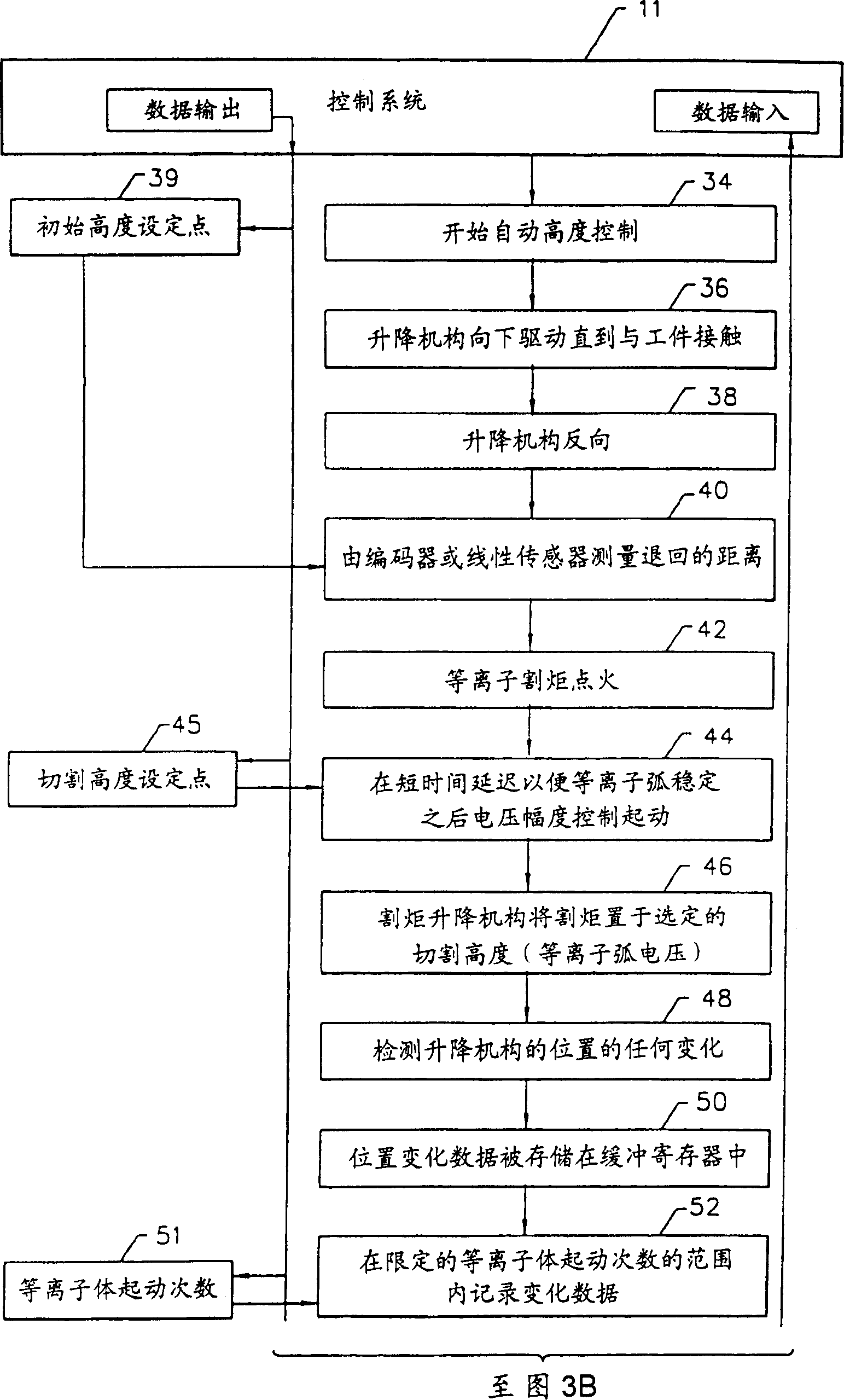

[0021] see now figure 1 , which shows a plasma arc cutting torch 10 . Plasma arc cutting torch 10 includes a nozzle member 12 and a tubular electrode 14 defining a longitudinal axis.

[0022] There are many different plasma arc torches equipped with the components used in the invention cited above. Since these torches are conventional and well known, they will not be described here. Similarly, there are many different types of power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com