Intelligent pipeline type automatic dewaterer for oil tank and pressure tank

A technology of intelligent pipelines and pressure tanks, applied in containers, large containers, packaging, etc., can solve the problems of low dehydration speed, difficulty in establishing a stable oil-water interface, sensor pollution, etc., and achieve the effect of easy installation and protection from pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

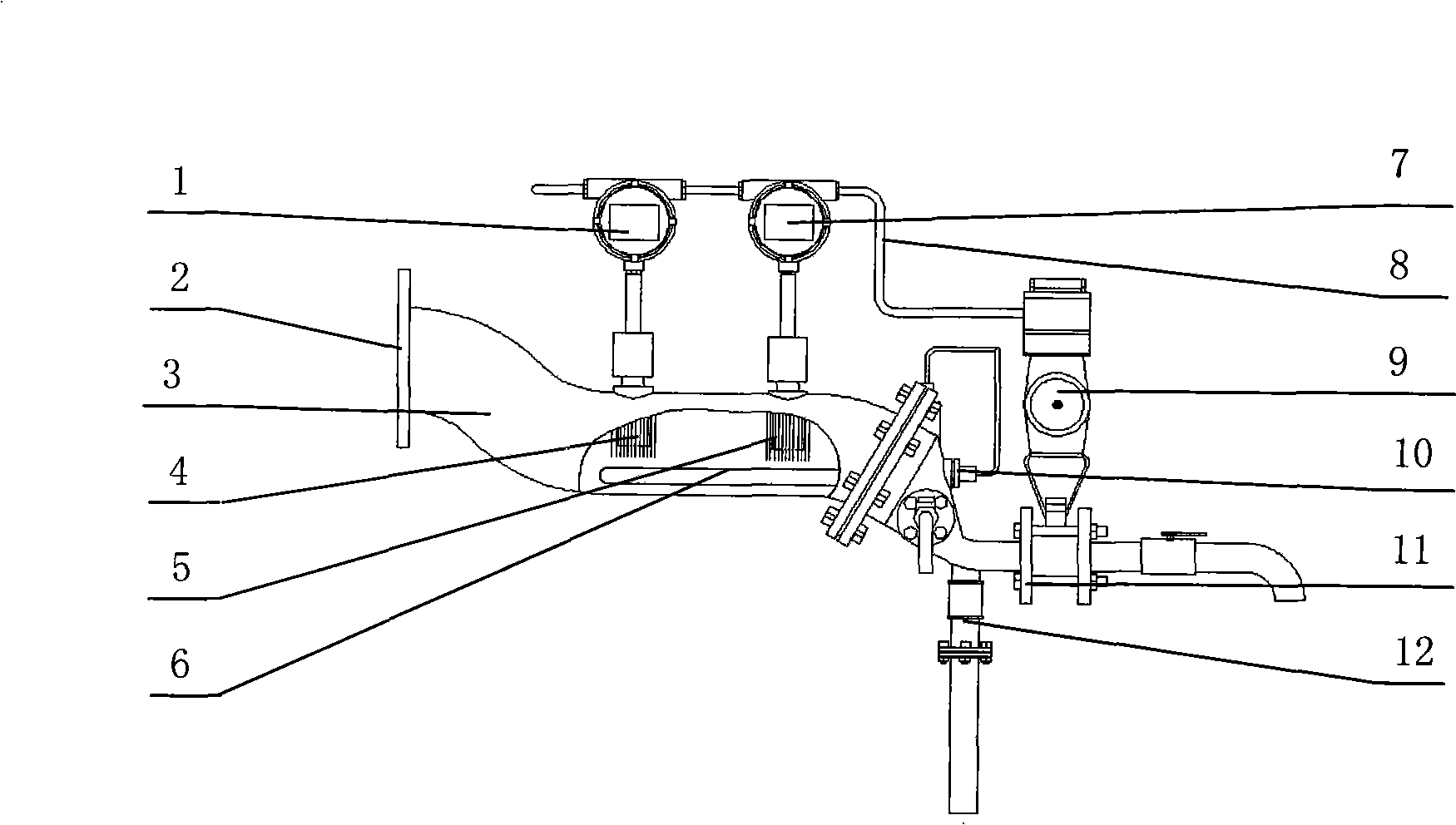

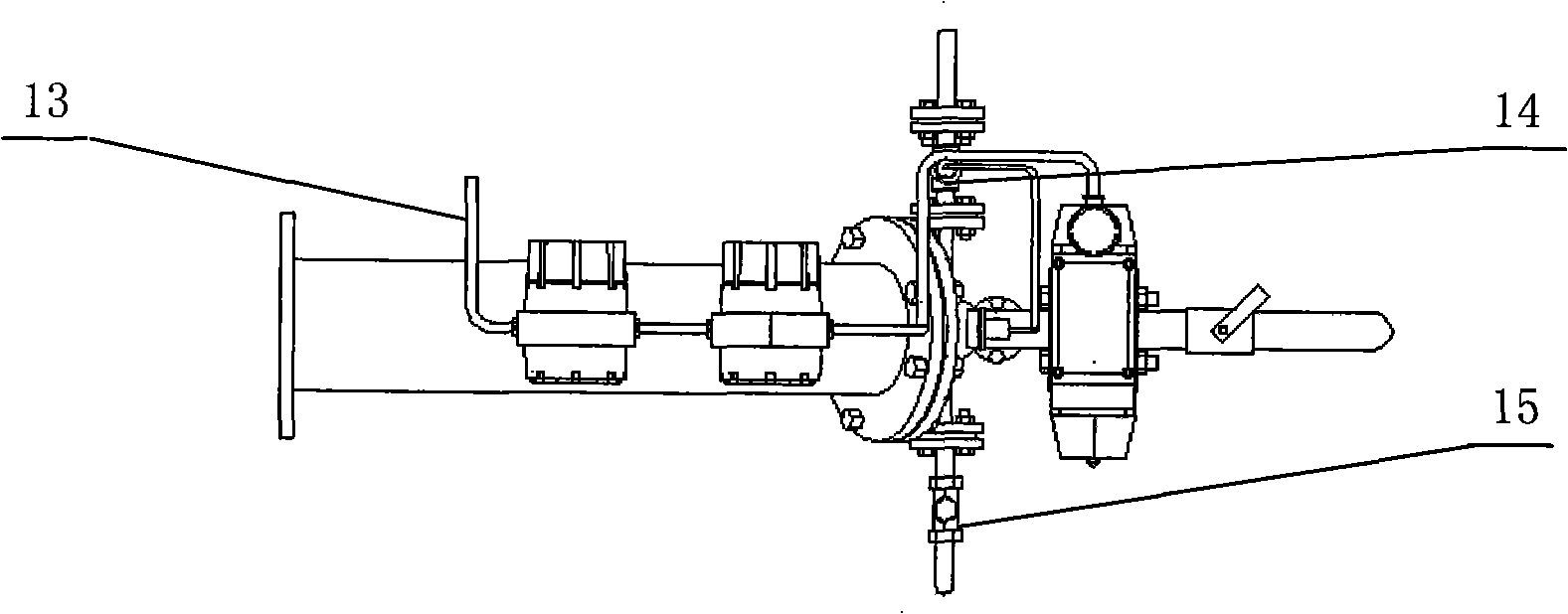

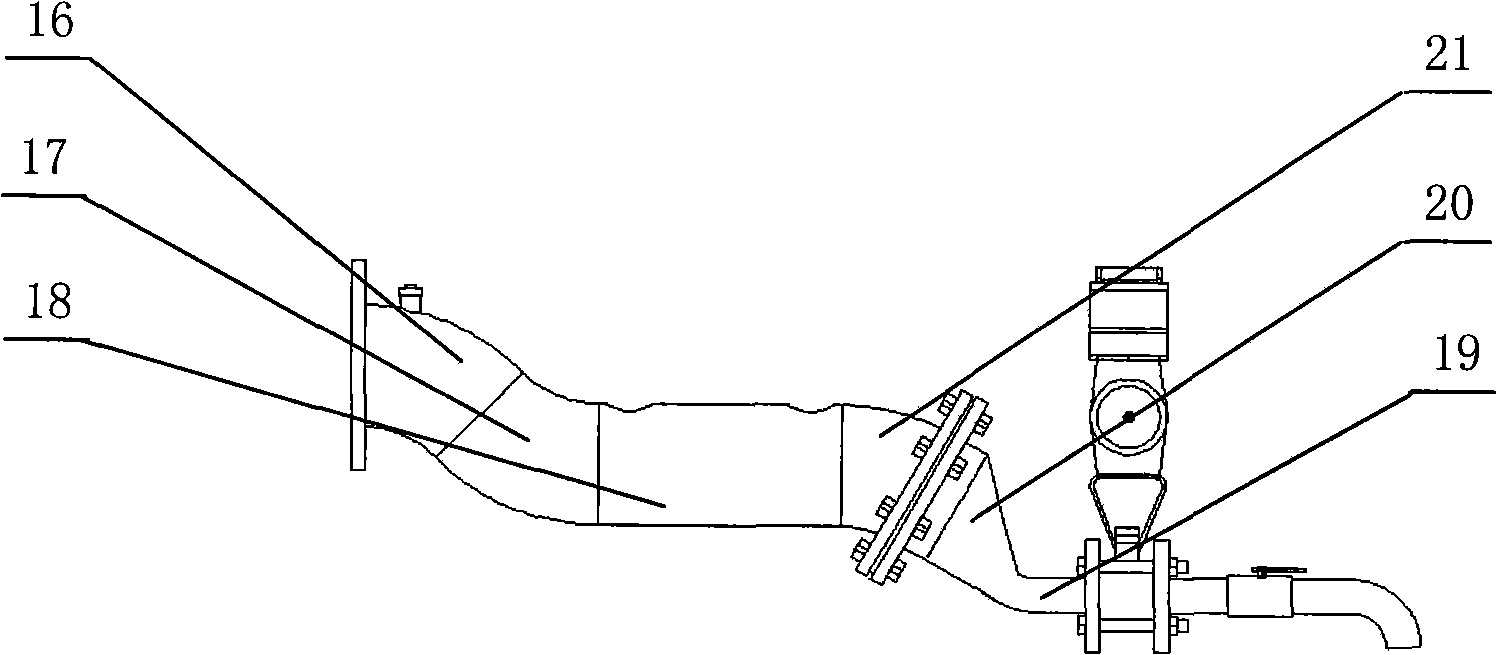

[0024] Such as Figure 1 to Figure 3 Shown: the present invention consists of the main detection controller 1, the inlet flange 2, the guide pipe 3, the main filter 4, the slave filter 5, the steam pipe 6, the slave detection controller 7, the connecting wire 8, the regulating valve 9, Temperature controller temperature bulb 10, outlet flange 11, support rod 12, cable 13, temperature controller regulating valve 14, steam trap 15, 45 degree elbow 16, 17, straight pipe 18, straight pipe 19, eccentric size head 20 , 30-degree elbow 21 composition. The inlet flange 2 of the draft tube 3 is connected to the on-site oil tank, and the outlet flange 11 is connected to the regulating valve 9; the sensors of the master and slave detection controllers are respectively connected to the draft tube 3, the main filter and The slave filter is respectively covered on the sensors of the master and slave detection controllers, and the signal output of the master and slave detection controllers are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com