Roller type superfine grinding pump

A roller-type, ultra-micro technology, applied in grain processing, etc., can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

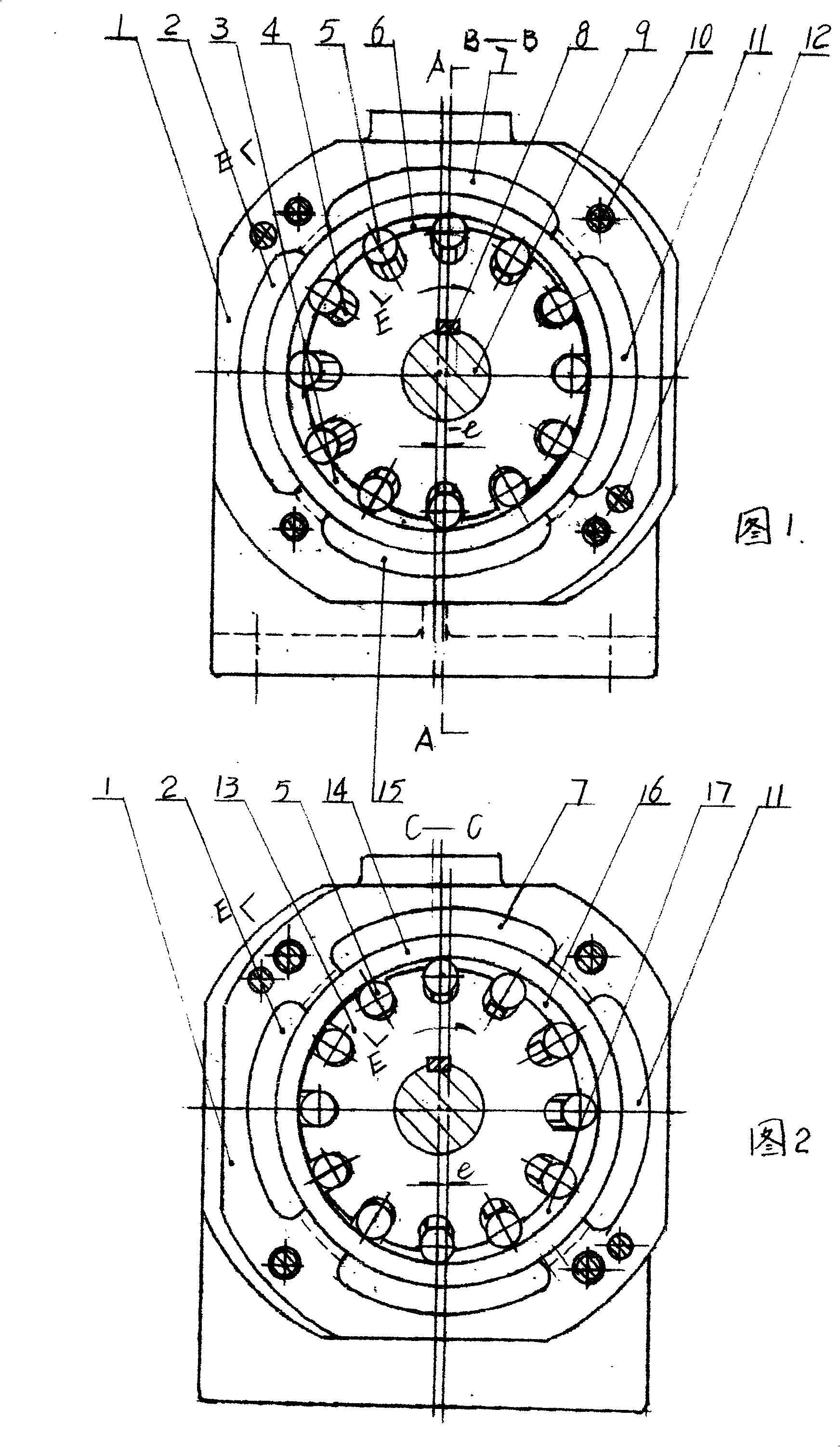

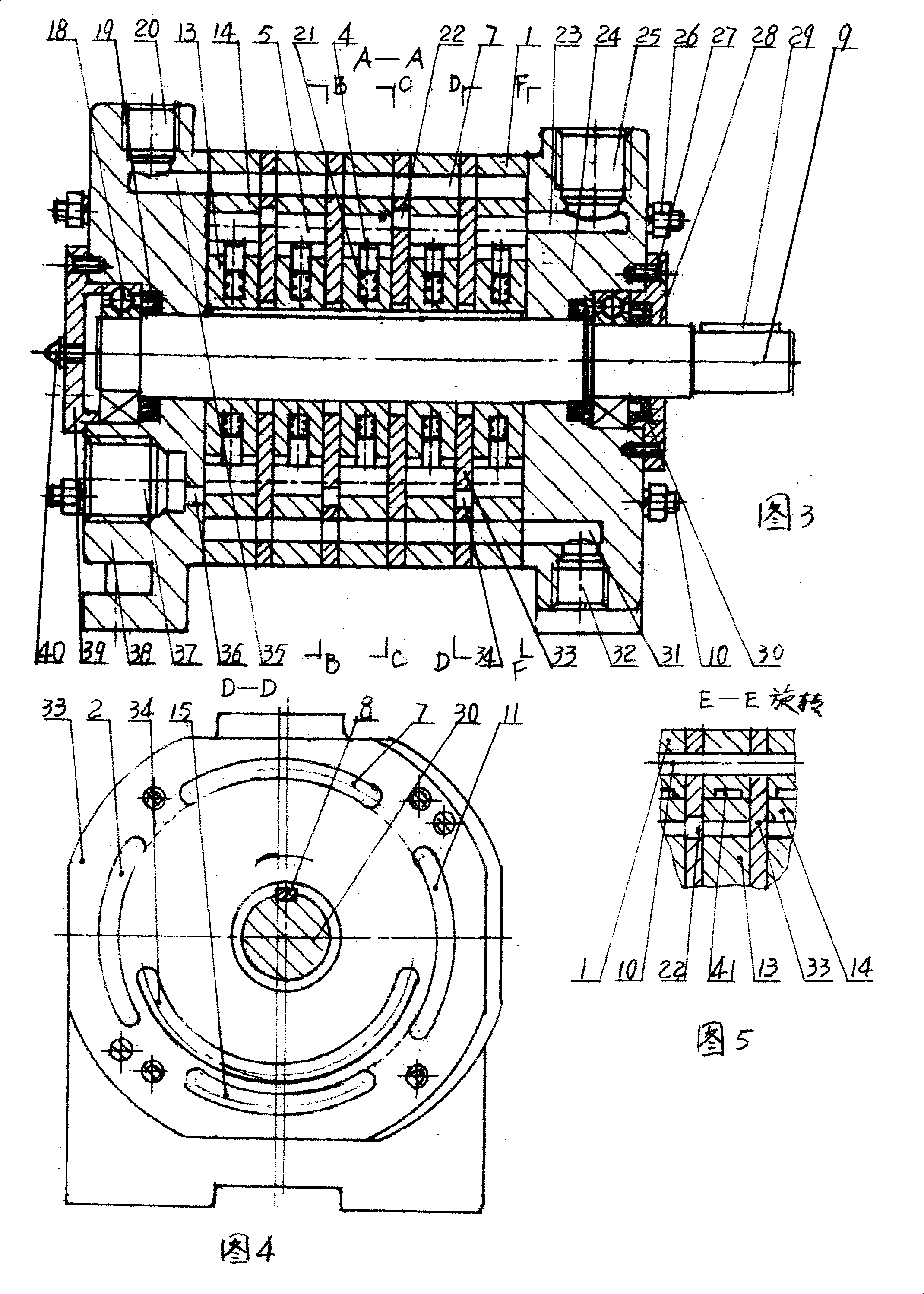

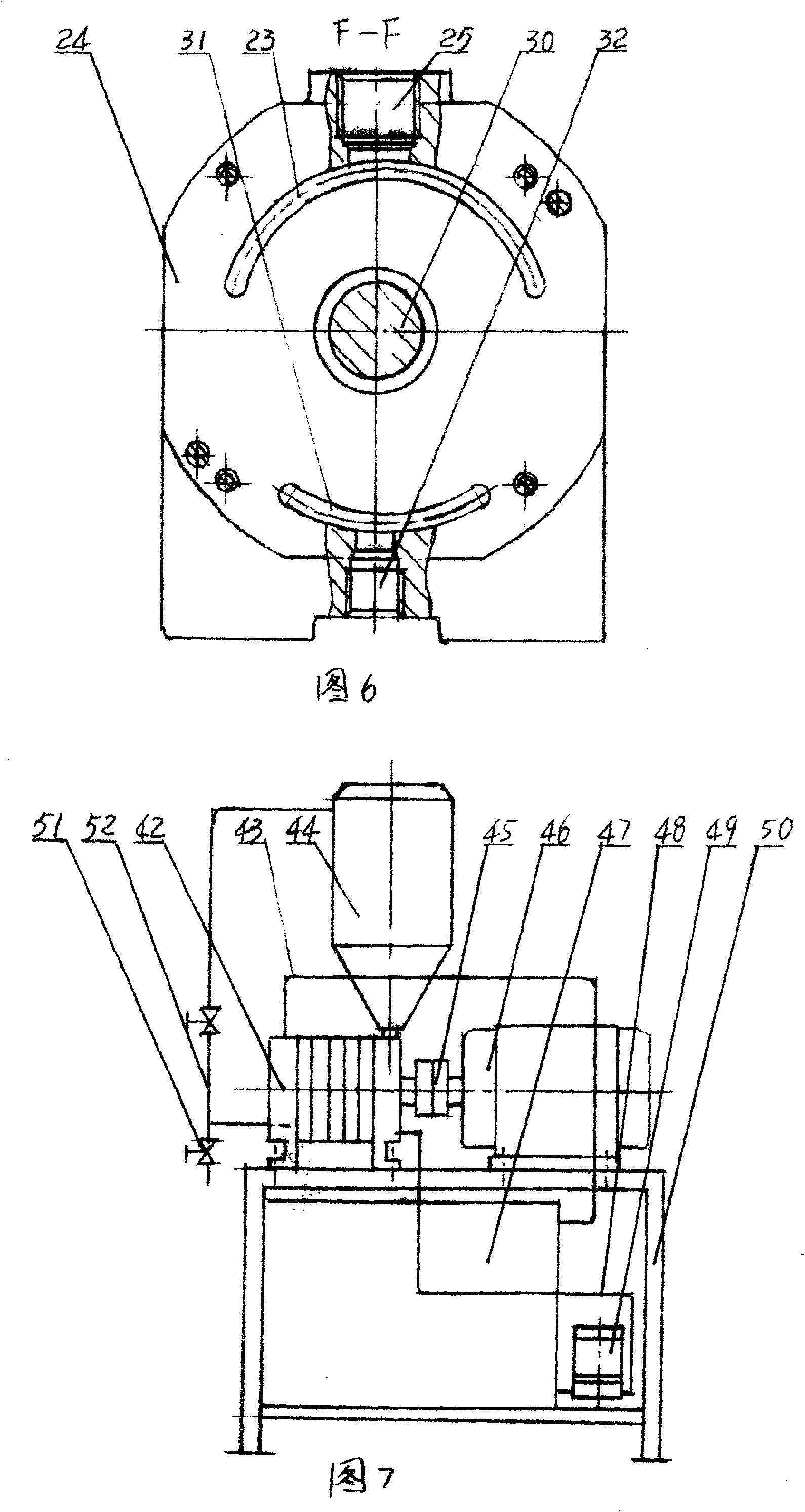

[0012] A further description of the roller-type ultrafine grinding pump of the present invention will be given below in conjunction with the description of the drawings and embodiments.

[0013]Referring to Fig. 1, Fig. 2 and Fig. 3, a plurality of rotors 13 are sleeved on the drive shaft 9 equipped with long flat keys 8. The two ends of drive shaft 9 are contained in the axle holes of front and rear pump covers 24,38 through bearing 18. Two lip-type sealing rings 119 of the upper sleeve of the shaft 9 are respectively contained in the shaft holes of the front and rear pump covers for the grease of the sealing lubricating bearing 18, preventing it from entering the pump chamber. Front and rear glands 28,39 are loaded on the front and rear pump covers 24,38 with screws 27, and press the bearing 18 to stop it from moving out of the pump cover. The lip type sealing ring II30 of adorning in the front gland 28 inner cavity can stop the outstretching end of grease along the shaft 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com