Embedded mounting method for reinforcing steel bar concrete box girder construction

A reinforced concrete and box girder technology, applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of shortening erection time, prolonging erection time, wasting construction period, etc., to shorten erection time, shorten construction period, and reduce construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

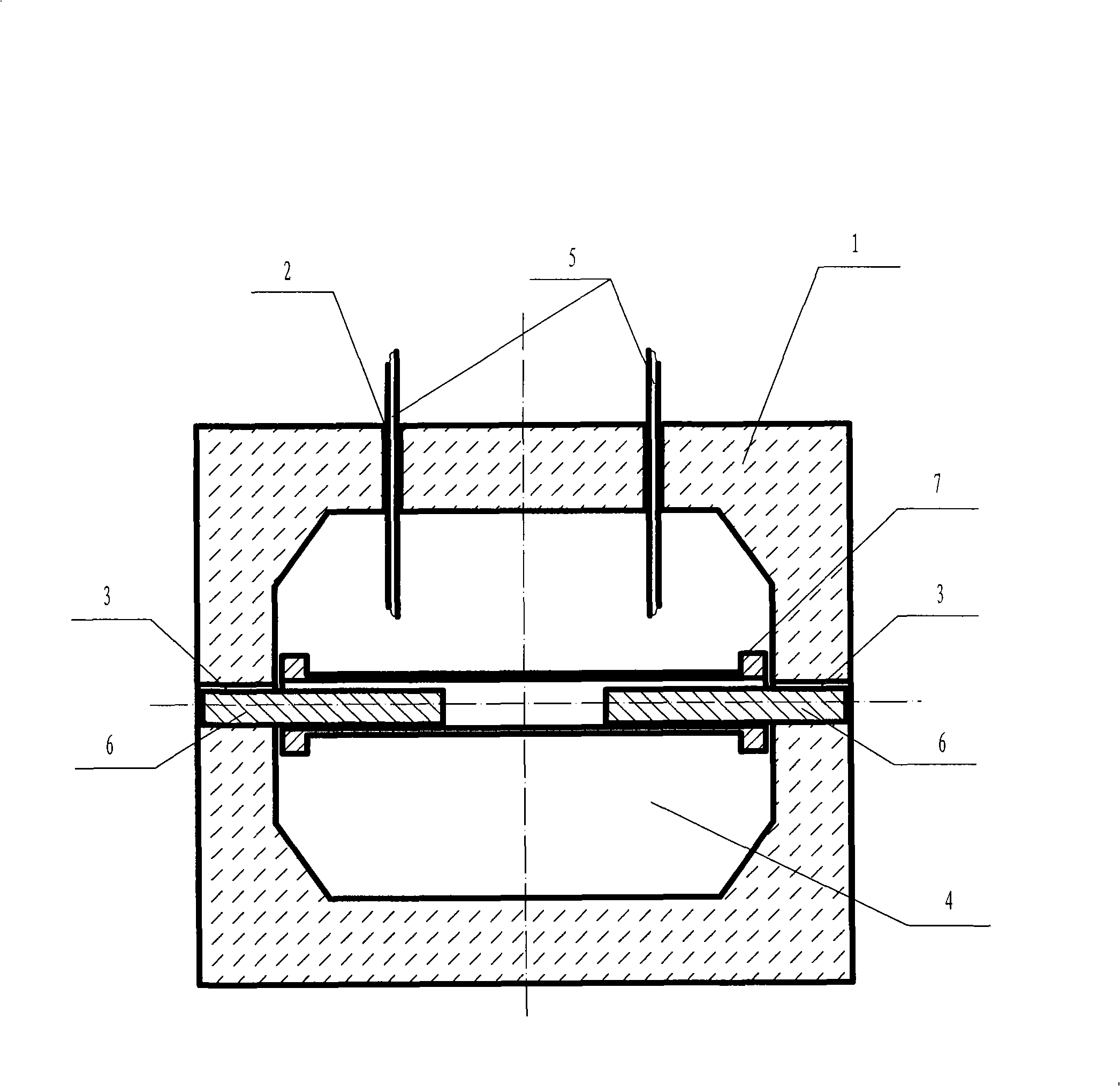

[0017] The erection and embedded installation method of reinforced concrete box girder of the present invention comprises the following steps:

[0018] 1. The reinforced concrete box girder is erected in a symmetrical erection method, and the embedded erection method is adopted when erecting the last reinforced concrete box girder in the middle;

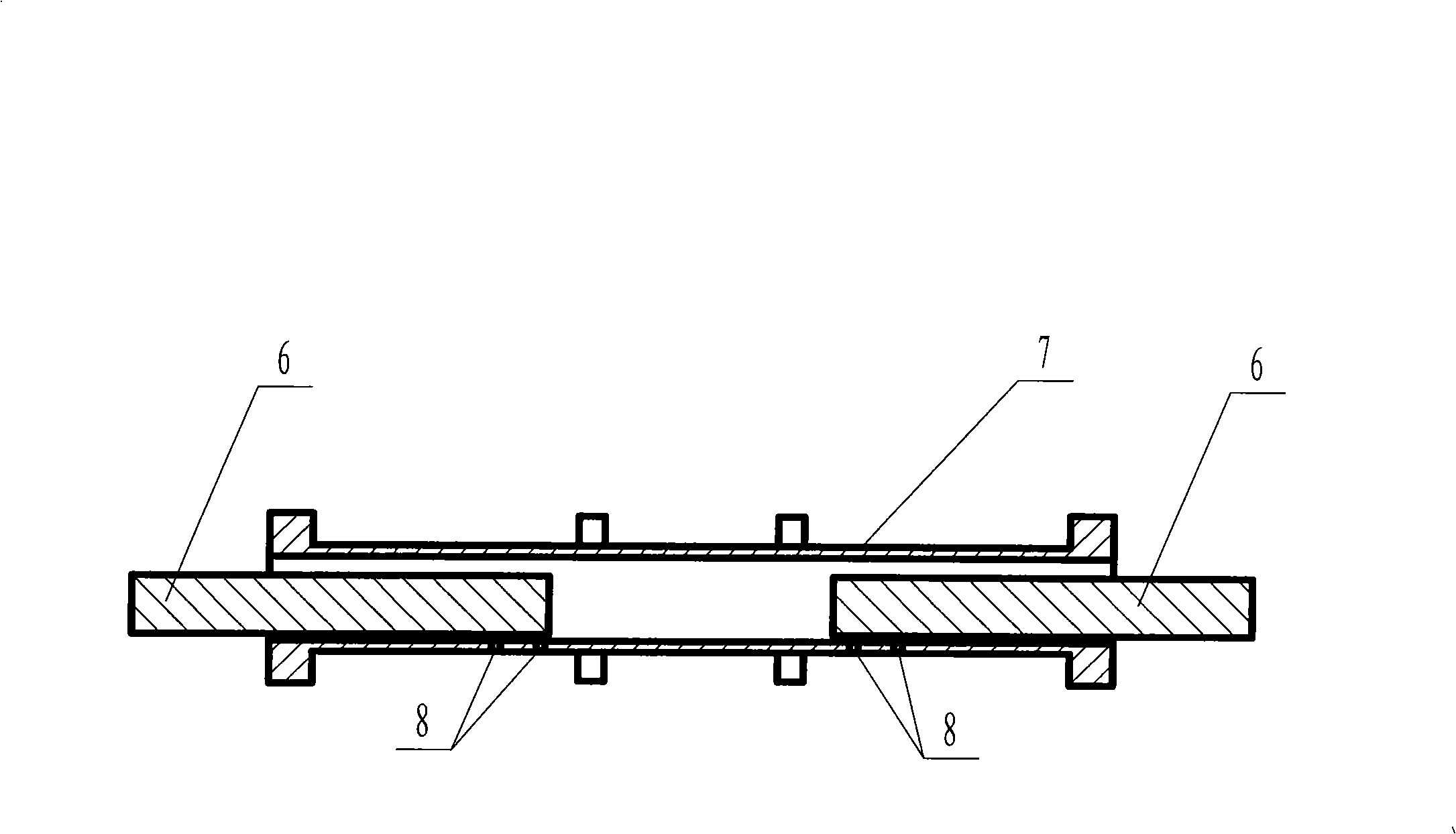

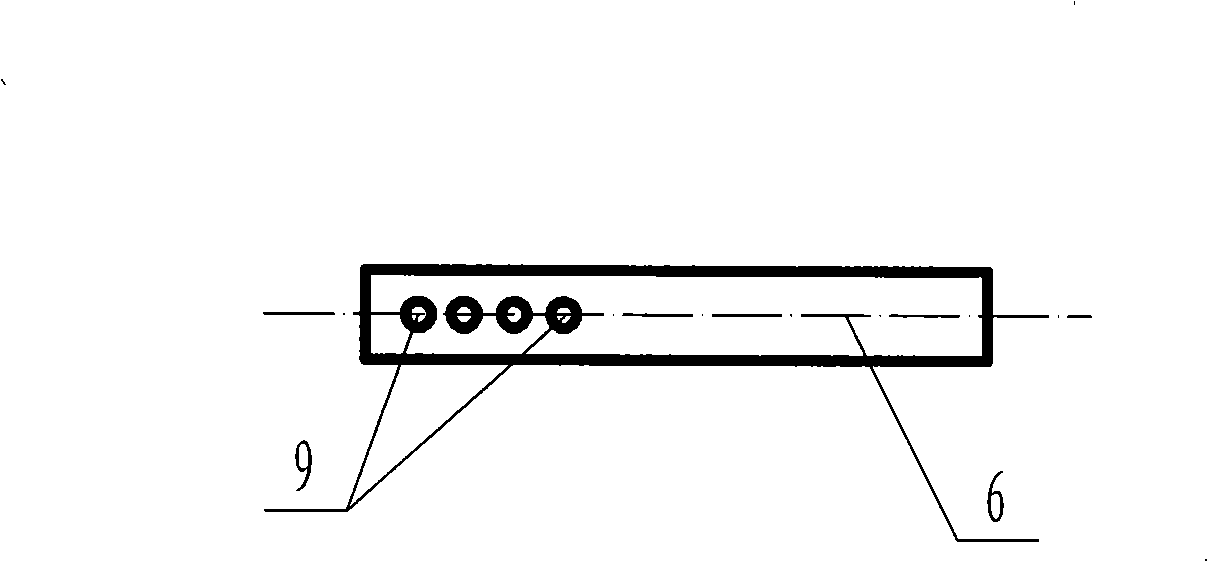

[0019] 2. Use two steel rods whose length is less than half of the width of the reinforced concrete box girder and whose length is greater than the wall thickness of the cavity in the reinforced concrete box girder, and put them into the stress sleeve. The length of the stress sleeve is less than that of the reinforced concrete box The width of the cavity in the beam is composed of the above two steel rods and the stress sleeve to form a telescopic sleeve, which is used as the stress rod when erecting the last piece of reinforced concrete box girder;

[0020] 3. Put the above stress sleeve into the hoisting reserved hole of the reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com