Horizontal drier usually for ceramic materials and method thereof

A technology of ceramic materials and drying methods, applied in the direction of drying solid materials, progressive dryers, heating to dry solid materials, etc., can solve the problems of complex structure of dryers, difficulty in replacing equipment parts, and a large number of components, etc., to achieve size reduction , structure and assembly simplification, equipment simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

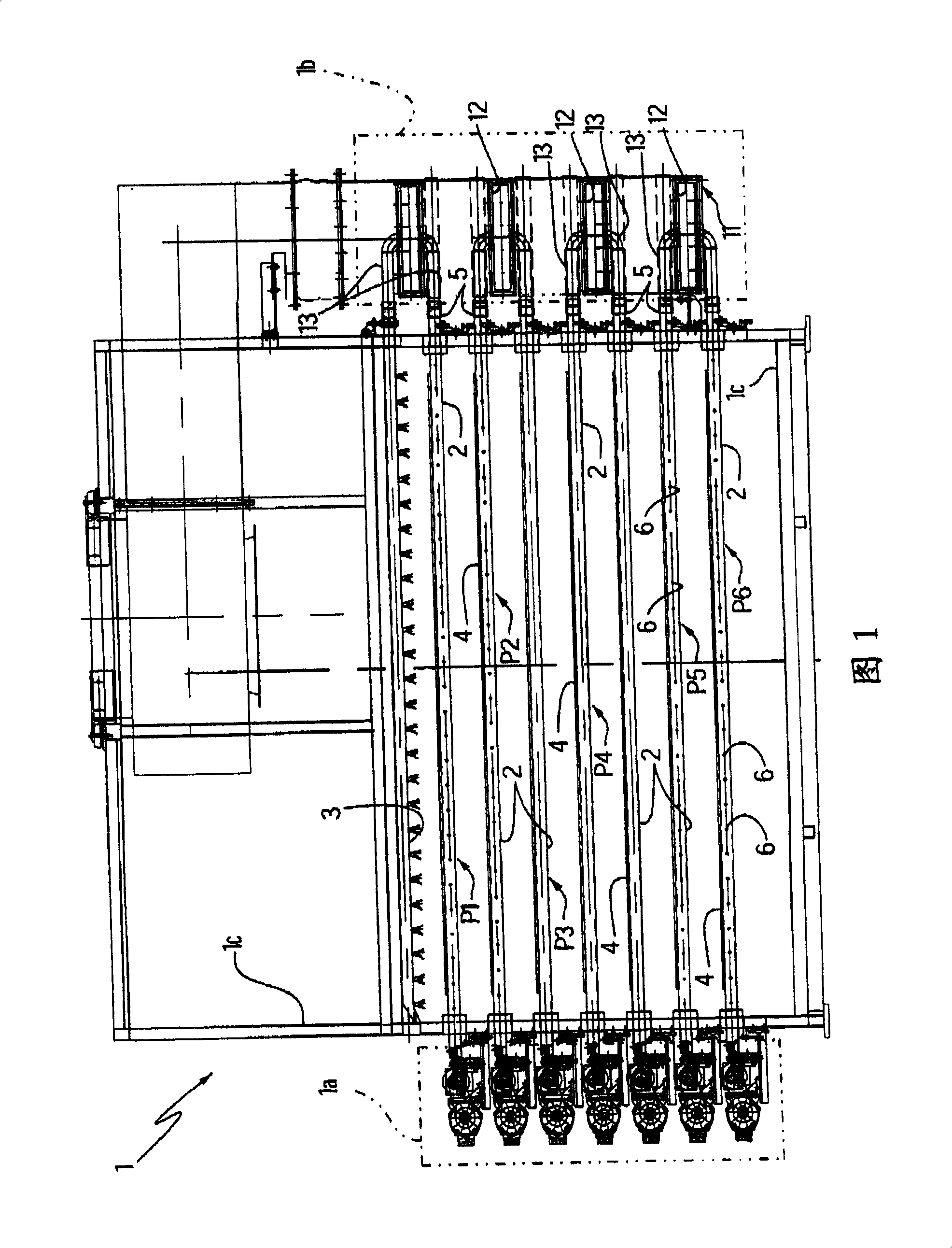

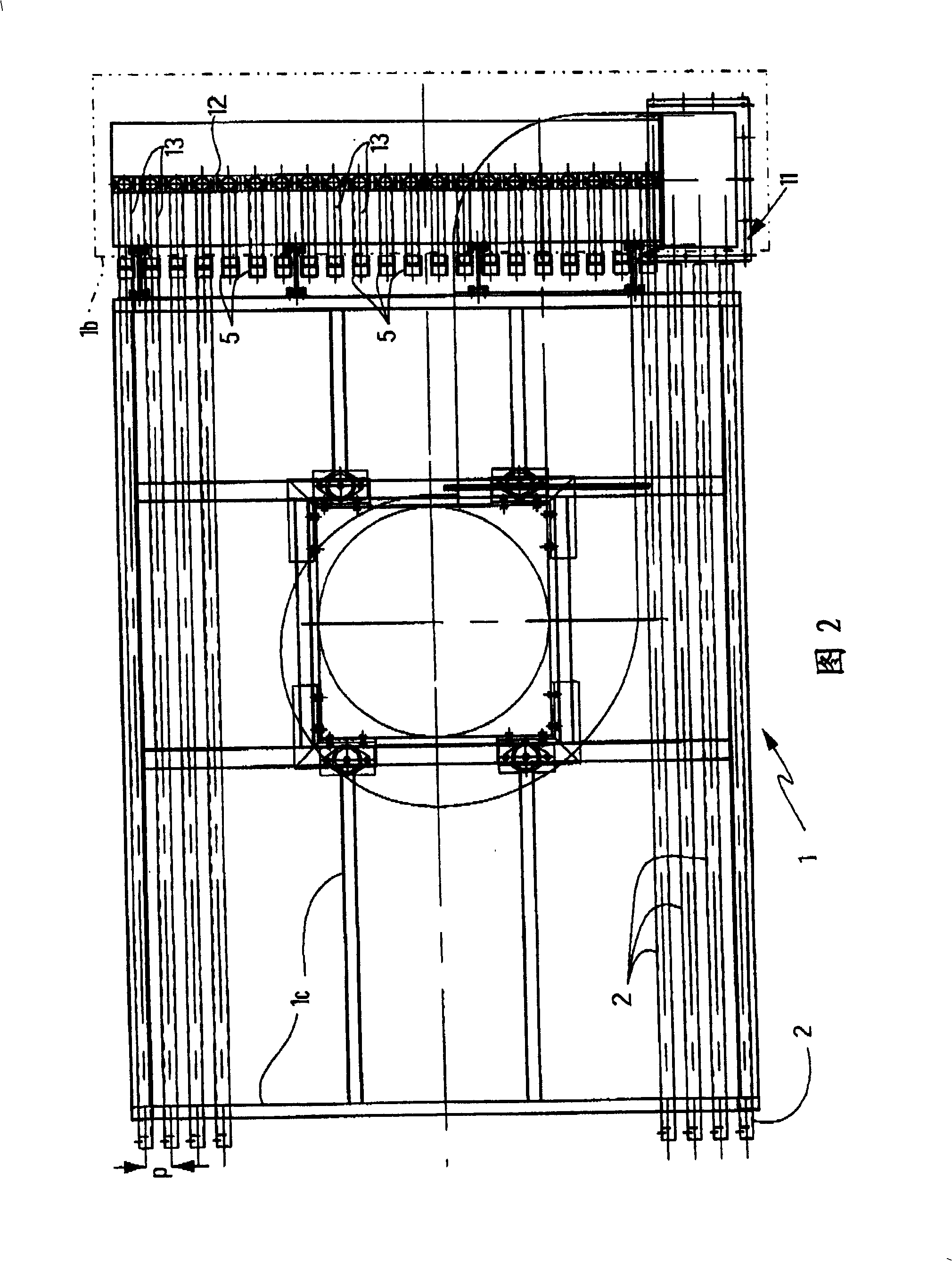

[0028] Referring to Figures 1 and 2, reference 1 generally designates a horizontal dryer consisting of a typically insulated closed box-like structure 1c defining an internal drying chamber for drying raw ceramic products 4 from the upstream line of dryer 1 .

[0029] The dryer 1 of this example is divided into seven levels indicated by arrows P1, P2, P3, P4, P5, P6 and P7, each level comprising a series of equally spaced (interval P) drums 2 and adapted to support the product 4 and convey the product from the inlet to the outlet of the dryer 1.

[0030] The drum 2 is interposed between the vertical side walls of the box-like structure 1c; and connected at their ends are the motor unit 1a and the hot air supply unit or blower unit 1b.

[0031] The motor unit 1a drives each drum 2 around its own rotation axis, and the supply unit 1b guides hot air into the hollow drum 2 so that the air introduced therein passes through a plurality of holes 6 formed on each drum 2 Blown to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com