Large span spatial structure CAD assembly analytical method

A technology of spatial structure and analysis method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as failure to reflect stiffness contribution, difficult operation, and easy operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

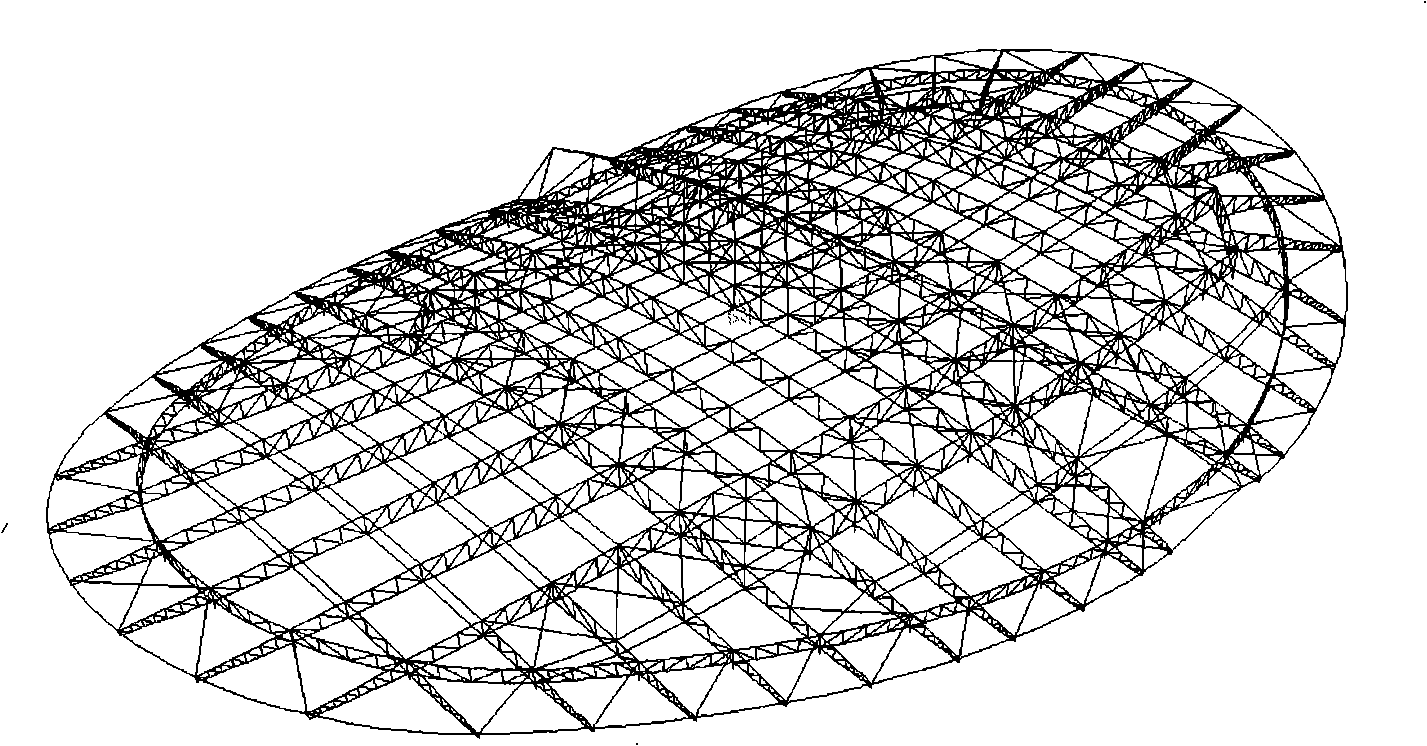

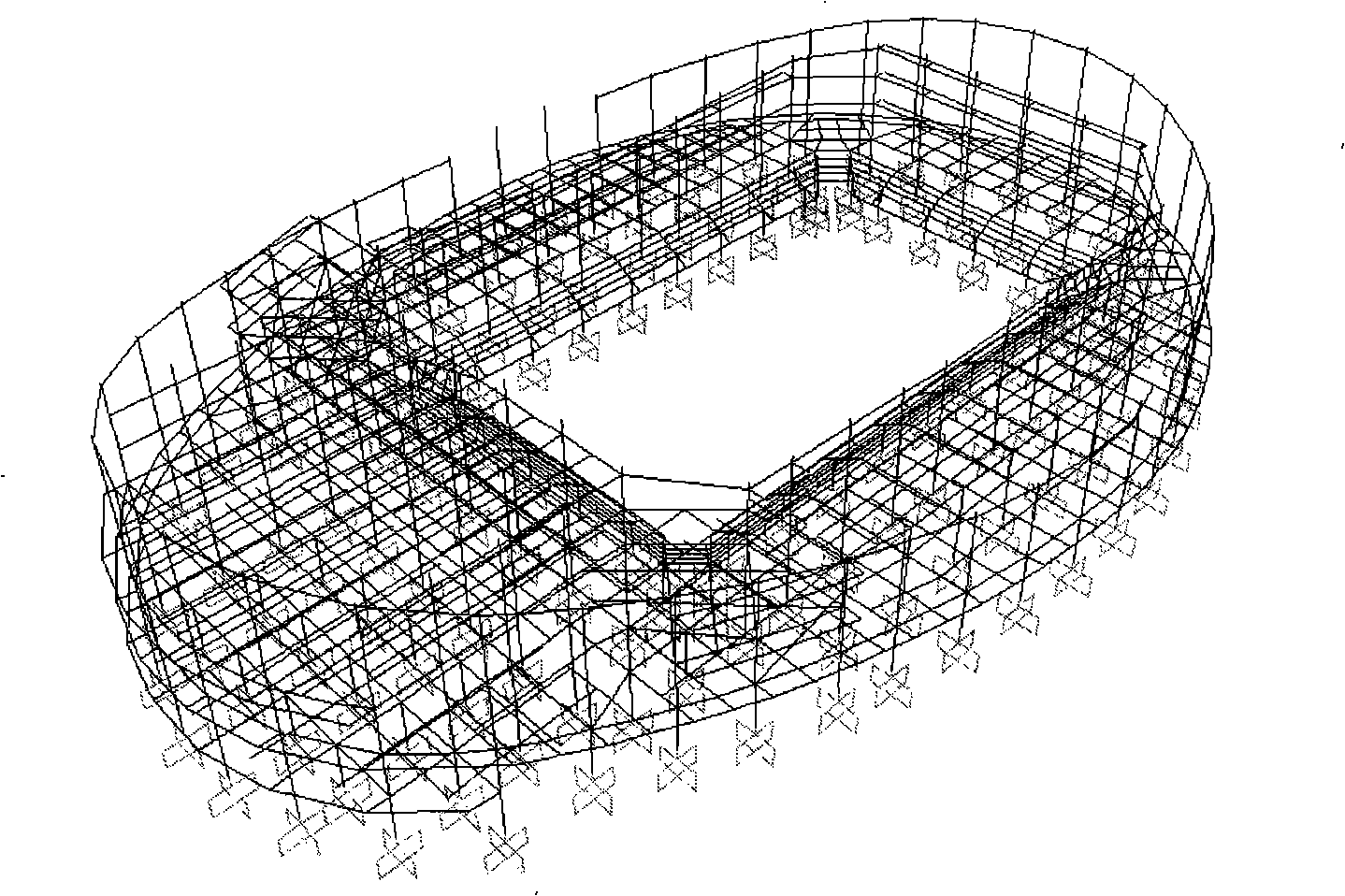

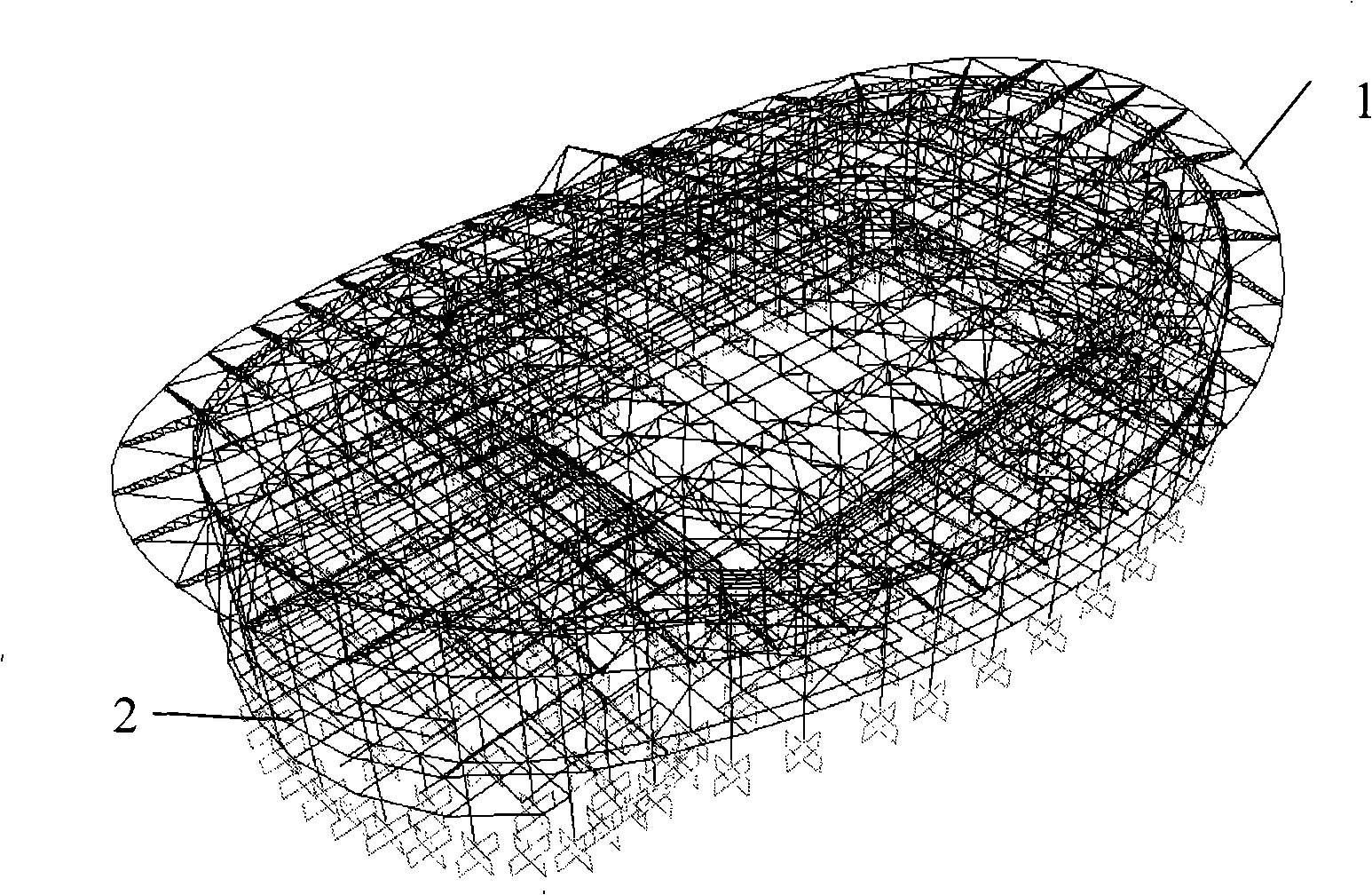

[0024] Please see attached Figure 1~3 . 1-The upper large-span space structure model, 2-The lower concrete structure model, 3-The final assembly model.

[0025] A kind of large-span spatial structure general assembly analysis technology of the present invention, described general assembly model 3, is jointly formed by upper large-span spatial structure model 1, and lower concrete structure model 2, and its specific steps are as follows, see Figure 4 .

[0026] First, use finite element analysis software (including SAP2000, ETABS, MIDAS, ANSYS, ABQUS) to establish models for the upper large-span space structure and the lower concrete structure that constitute the whole. Then, the upper long-span space structure model 1, the lower concrete structure model 2, and the two models are combined into a complete assembly model 3. The deformation and mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com