Electrode slice guide plate structure for lithium battery coiling core winder

A winding machine and electrode sheet technology, applied in the field of electrode sheet guide plate structure, can solve the problems of lithium battery self-discharge aggravation, battery heating, short circuit, etc., and achieve the effect of improving self-discharge resistance and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

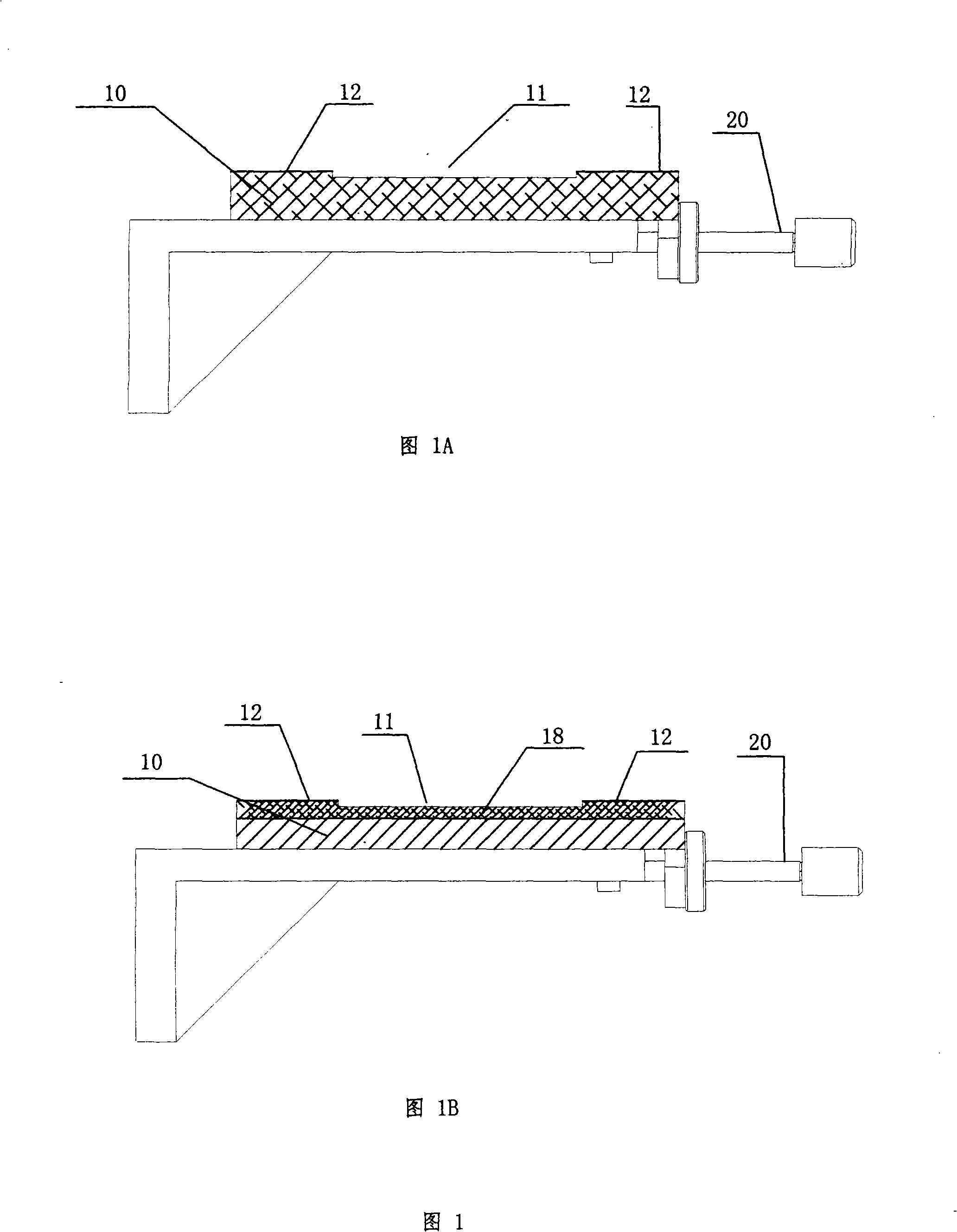

[0018] The electrode sheet guide plate structure of the lithium battery core winding machine of the present invention, as shown in Figure 1, includes a long strip-shaped guide plate body 10 with a "concave" cross section and an adjustment mechanism 20 connected to the winding frame, the guide plate body In the middle of 10 is the guide groove 11 for transmitting the electrode sheet, and the two sides of the guide plate 10 are frame 12, and the guide plate body 10 is made of a non-conductive hard material as a whole, as shown in Figure 1A; or, only the surface of the guide groove 11 A non-conductive hard material layer 18 is attached or inlaid on the inner surface of the side frames 12 , as shown in FIG. 1B .

[0019] In this embodiment, the non-conductive hard material is oxide ceramics, machinable ceramics, aluminum oxide ceramics or glass, or hard engineering plastics polysulfone, reinforced nylon 1010 or reinforced polycarbonate.

Embodiment 2

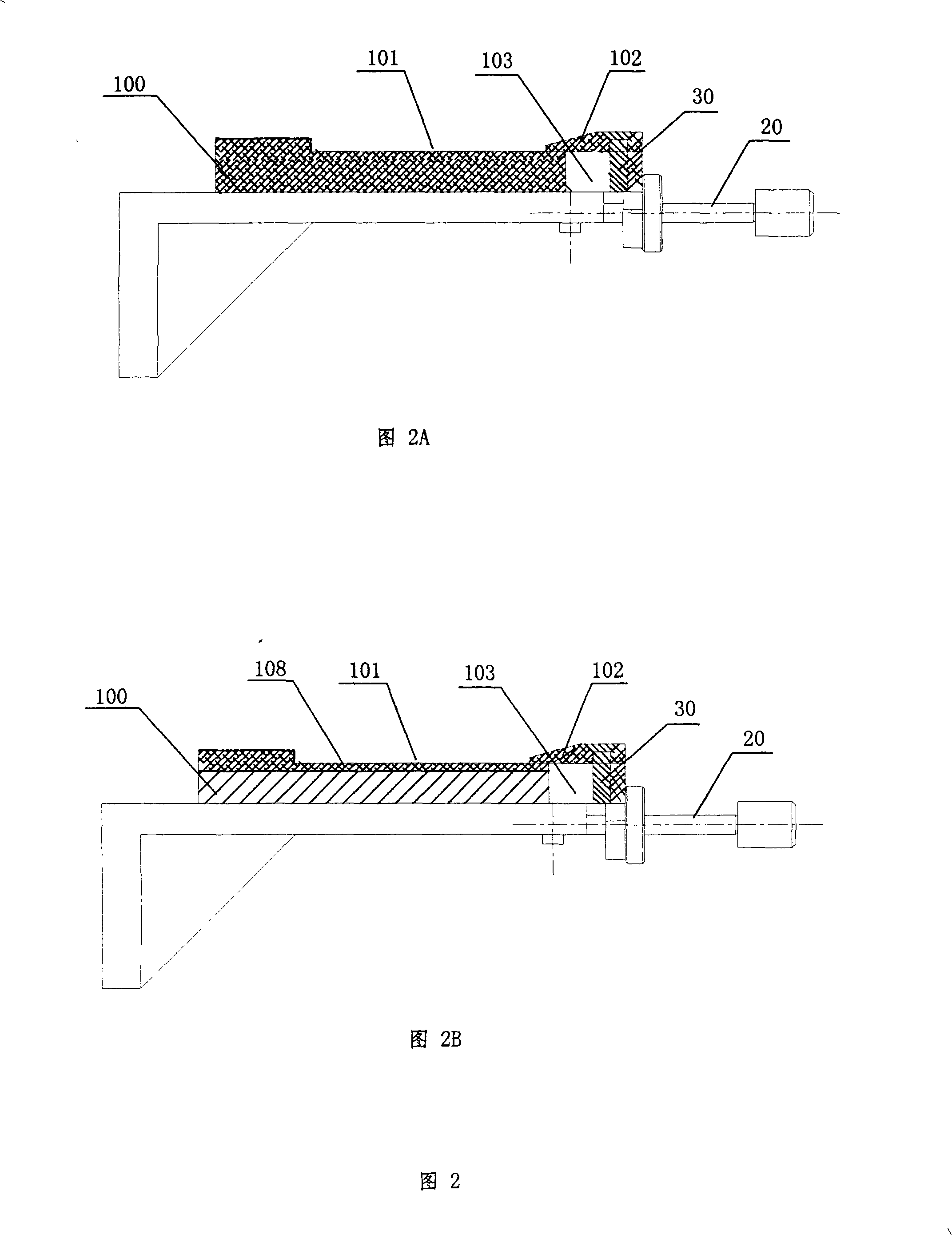

[0021] The electrode sheet guide plate structure of the lithium battery core winding machine of the present invention, as shown in FIG. Slot 101, one side of the guide plate body 100 is provided with a movable frame 102 that can move along the width direction of the guide plate body to adjust the width of the guide groove 101; the movable frame 102 is made of non-conductive hard material; the guide plate body 100 There is a chute 103 parallel to the width direction, the movable frame 102 is connected with the guide plate body 100 by means of a screw 30, and the screw 30 can move in the chute 103 to adjust the position of the movable frame 102; The whole guide plate body 100 is also made of non-conductive hard material (as shown in FIG. 2A ), or only a layer of non-conductive hard material 108 is attached on the surface of the guide groove 101 (as shown in FIG. 2B ).

[0022] In this embodiment, the non-conductive hard material is oxide ceramics, machinable ceramics, aluminum o...

Embodiment 3

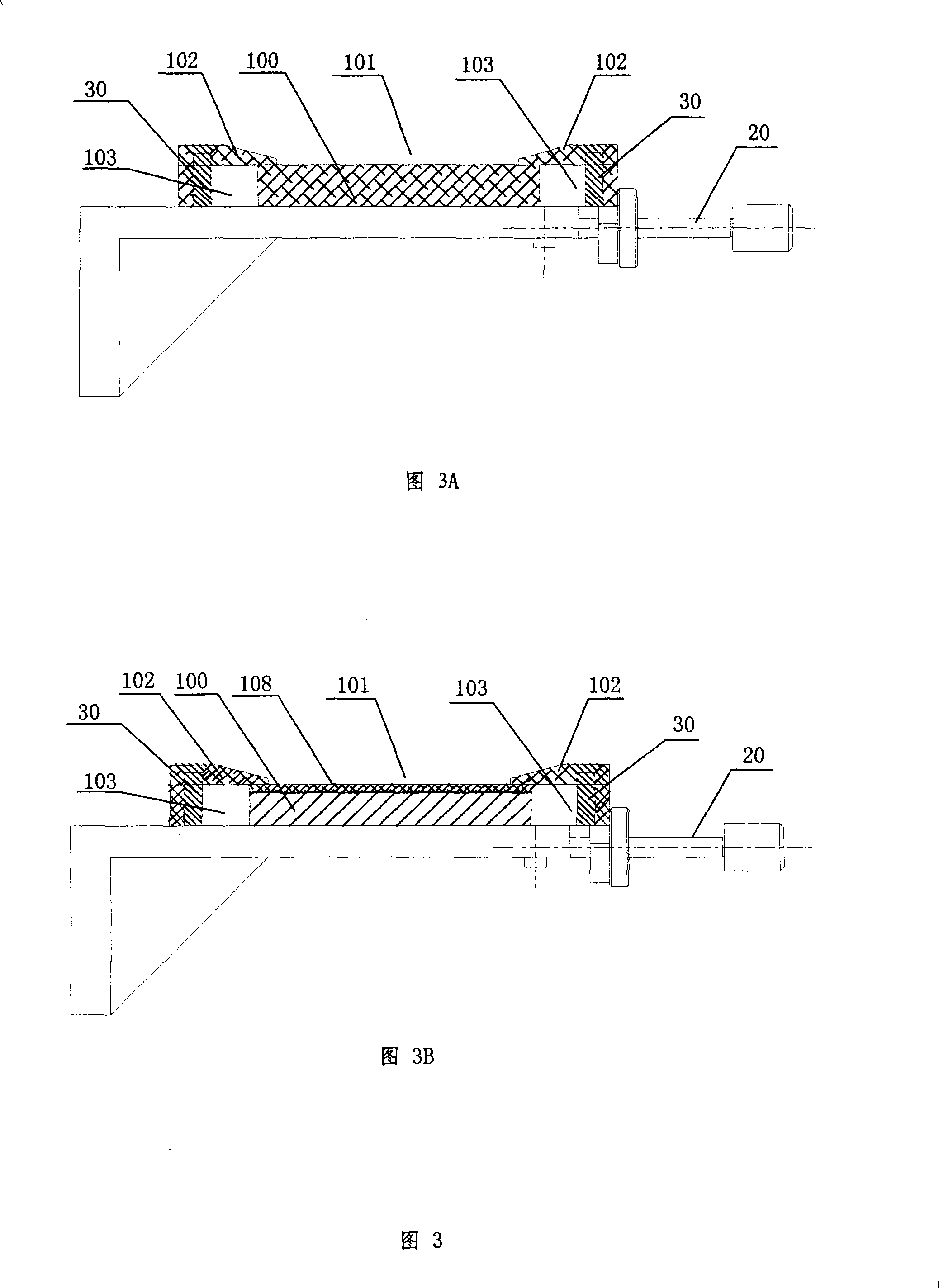

[0024] The electrode sheet guide plate structure of the lithium battery core winding machine of the present invention, as shown in FIG. Groove 101, the both sides of described guide plate body 100 are all provided with movable frame 102 that can move along the width direction of guide plate body to adjust the width of guide groove 101; This movable frame 102 is made of non-conductive hard material; Described guide plate body 100 is provided with a chute 103 parallel to the width direction, the movable frame 102 is connected with the guide plate body 100 by means of a screw 30, and the screw 30 can move in the chute 103 to adjust the position of the movable frame 102; The guide plate body 100 as a whole is also made of a non-conductive hard material (as shown in FIG. 3A ), or only the surface of the guide groove 101 is attached or embedded with a layer of non-conductive hard material 108 (as shown in FIG. 3B ). ).

[0025] In this embodiment, the non-conductive hard material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com