Multifunctional plant cover building machine

A multi-functional and vegetation technology, applied in the fields of planting method, sowing, application, etc., can solve the problems of increasing the machining and manufacturing cost of vegetation construction, affecting work efficiency, uneven force on the pusher plate, etc., to achieve large-scale mechanized operation, Reasonable structure design and the effect of improving trenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

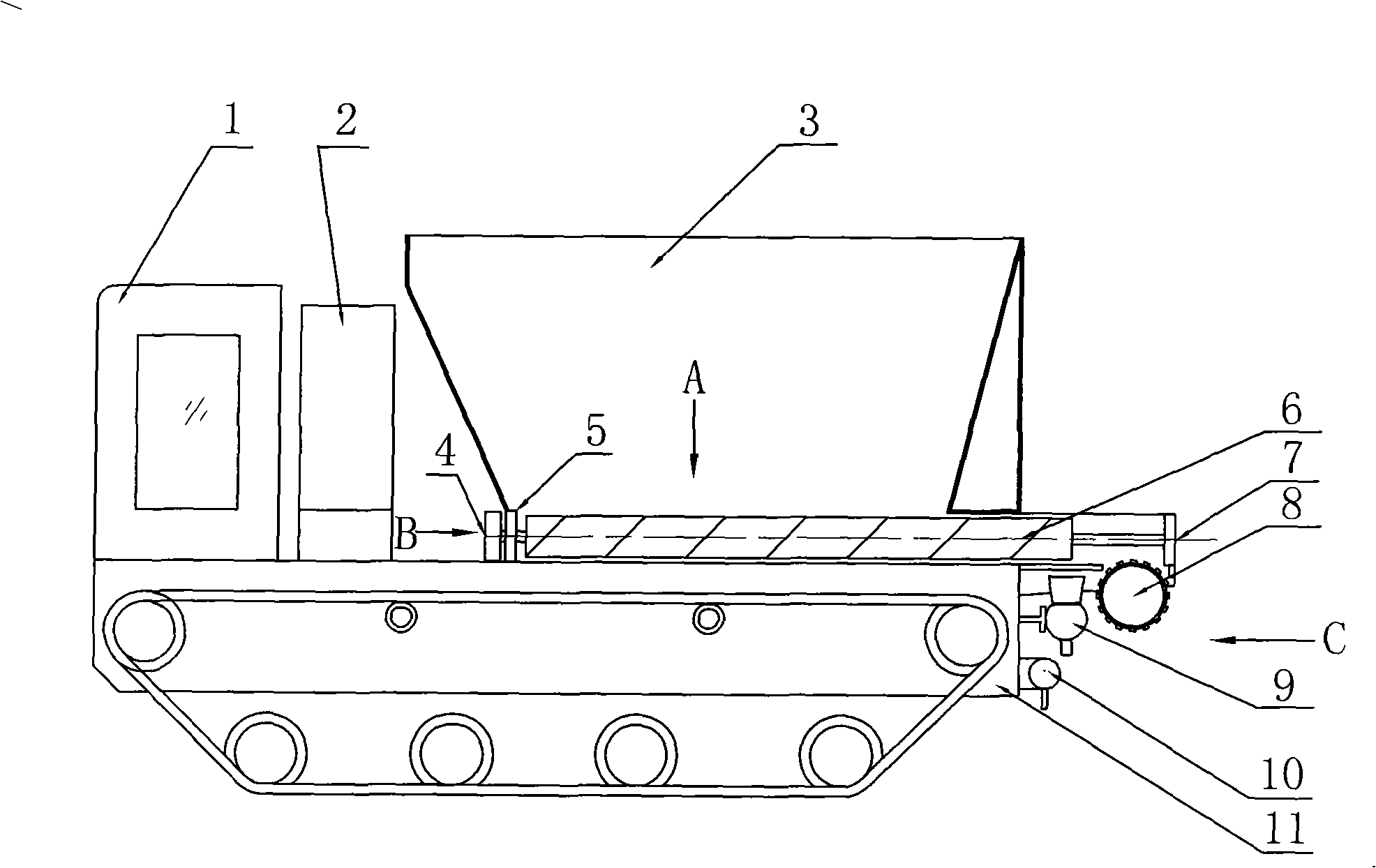

[0030] Such as Figure 1 to Figure 5 The multifunctional vegetation construction machine shown includes the control room 1, the driving mechanism, the car body 11, the loading box 3, the feeding mechanism, the transmission mechanism, the ditching mechanism and the planter 9, and the rear part of the loading box 3. There is a discharging port, and a horizontally rotating paver 8 is arranged below the discharging port. The paver 8 is installed on the side plate drawn from the car body 1. The feeding mechanism is connected with the transmission mechanism, and the transmission mechanism is connected with the engine. It operates under the drive of the engine, and the vehicle driving and paving operations are all carried out in the control room 1.

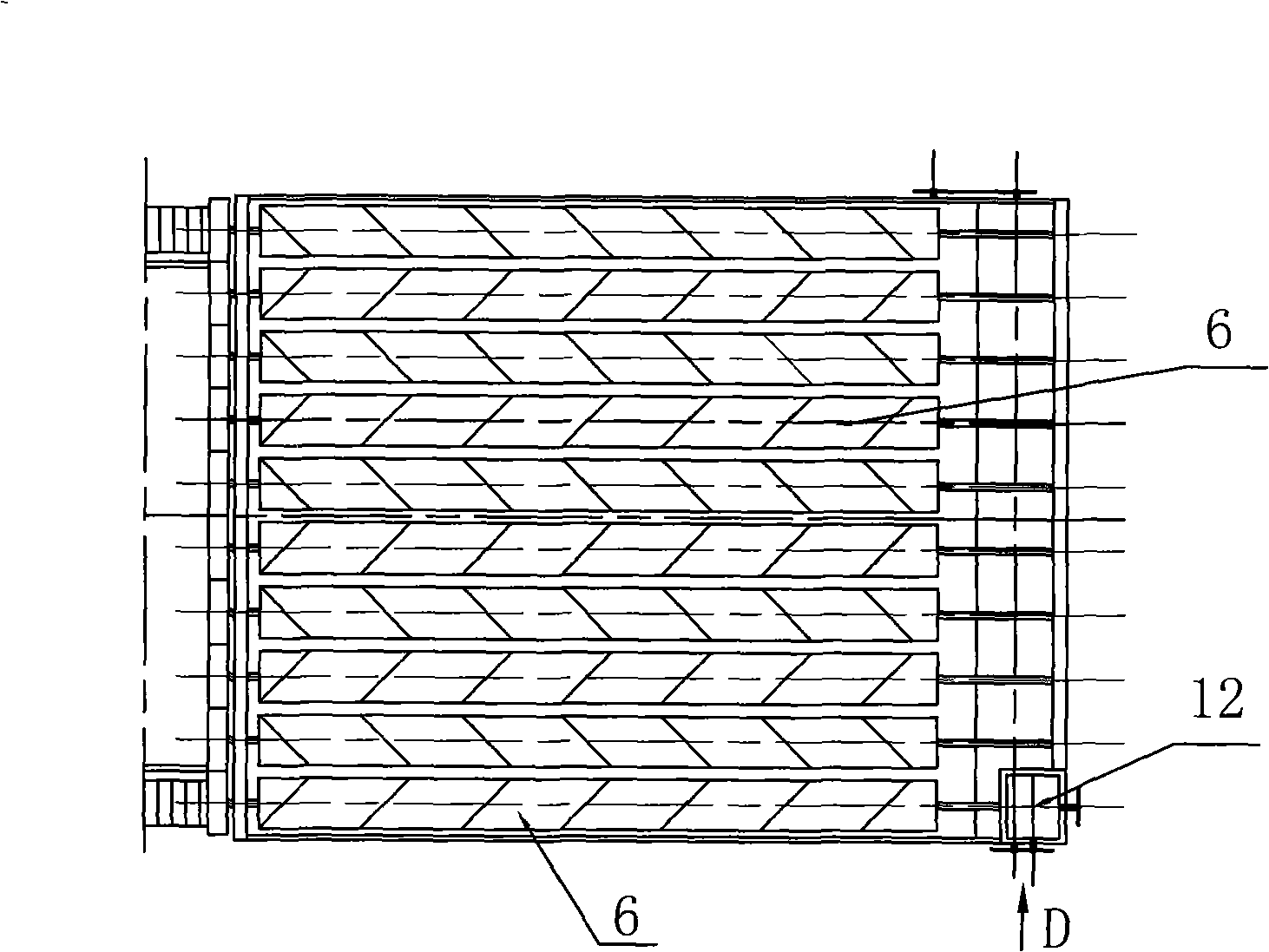

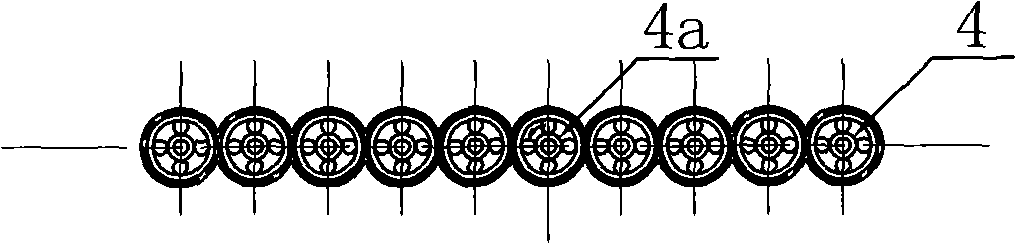

[0031] The feeding mechanism is 10 parallelly arranged spiral shafts 6. The front bearing seat plate 5 and the rear bearing seat plate 7 are arranged transversely on the car body 11. The two bearing seat plates are parallel to each other, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com