Hollow rack and manufacturing method, hollow rack end diameter reducing method and apparatus

A technology of hollow rods and gear rods, which is applied in the direction of hoisting devices, components with teeth, portable lifting devices, etc., can solve problems such as thread looseness, ball joint 210 falling off, end 203 can not increase the hardness, etc., to achieve increased Strength and the effect of reducing processing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

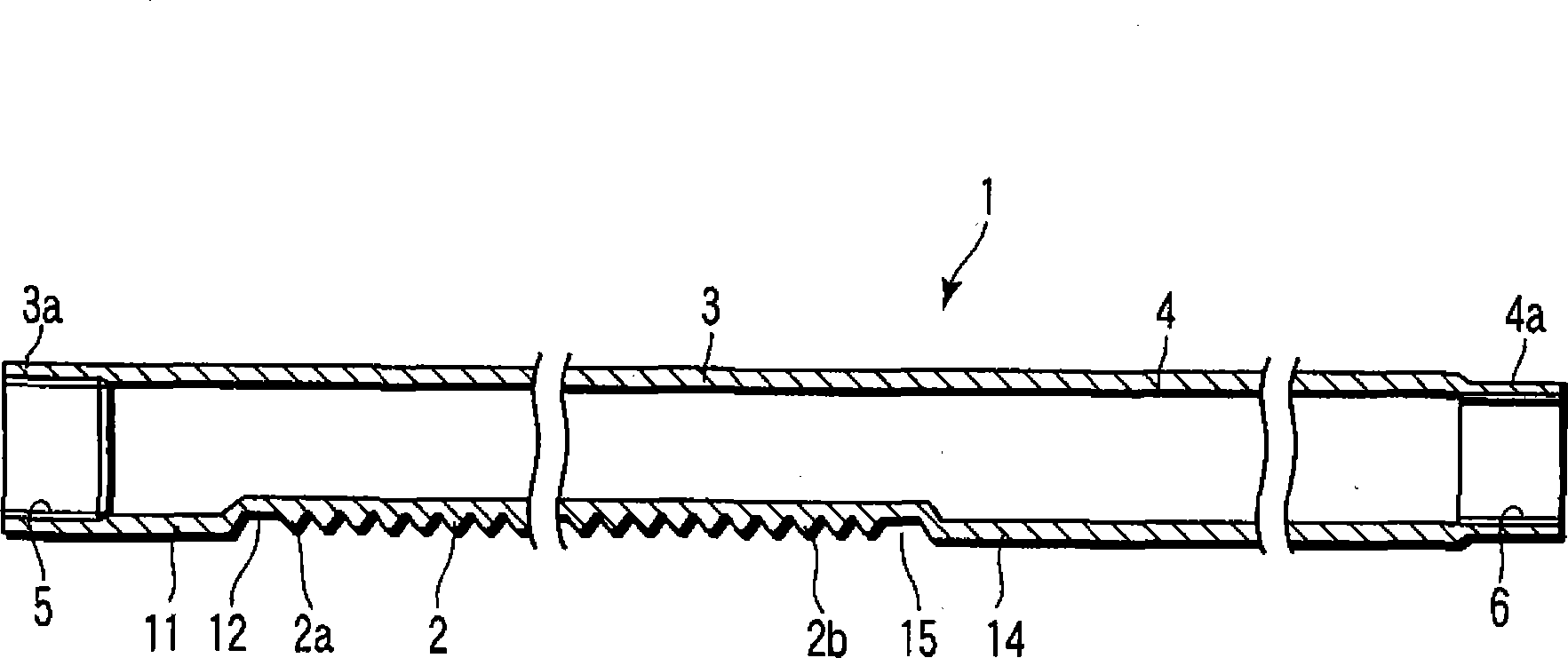

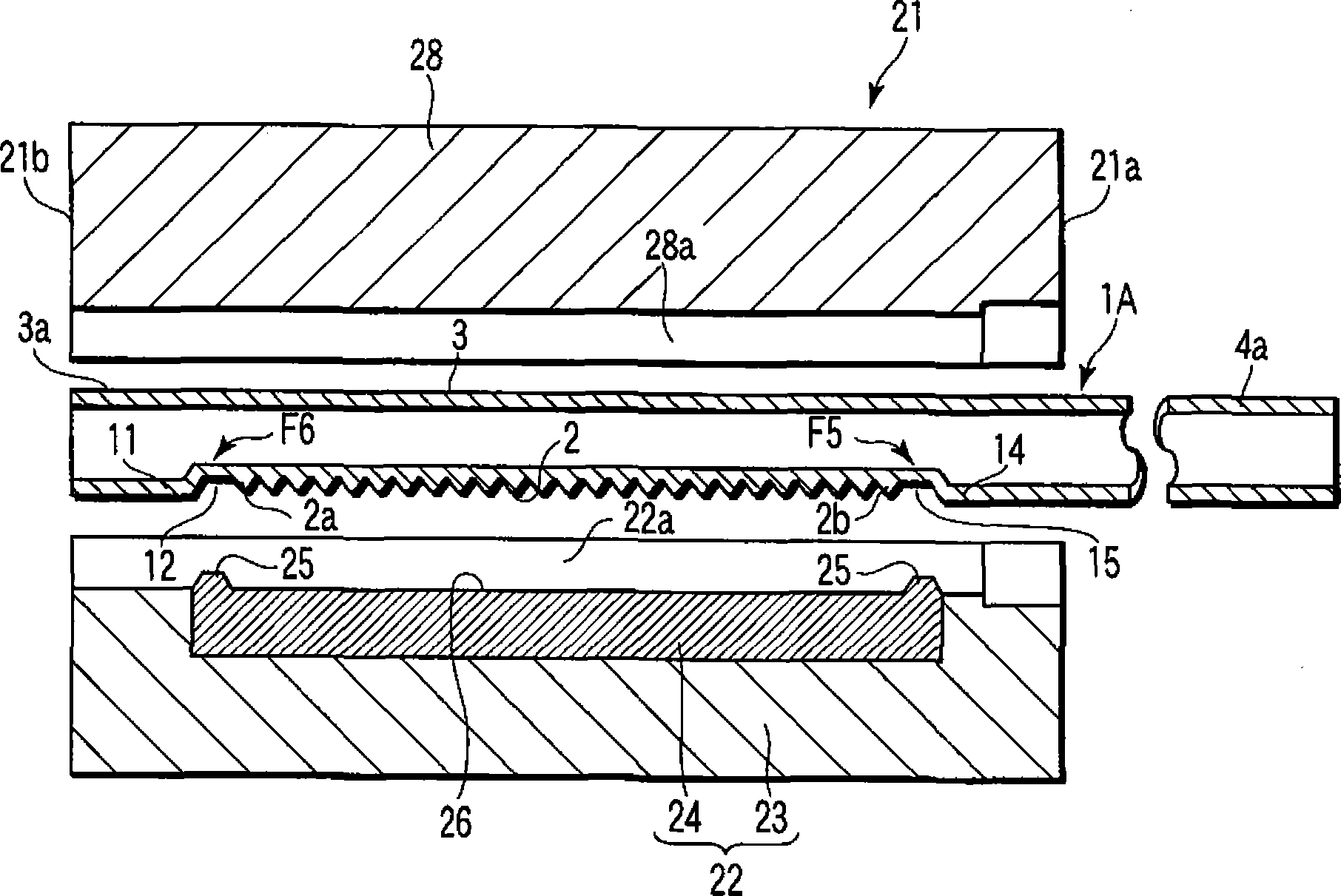

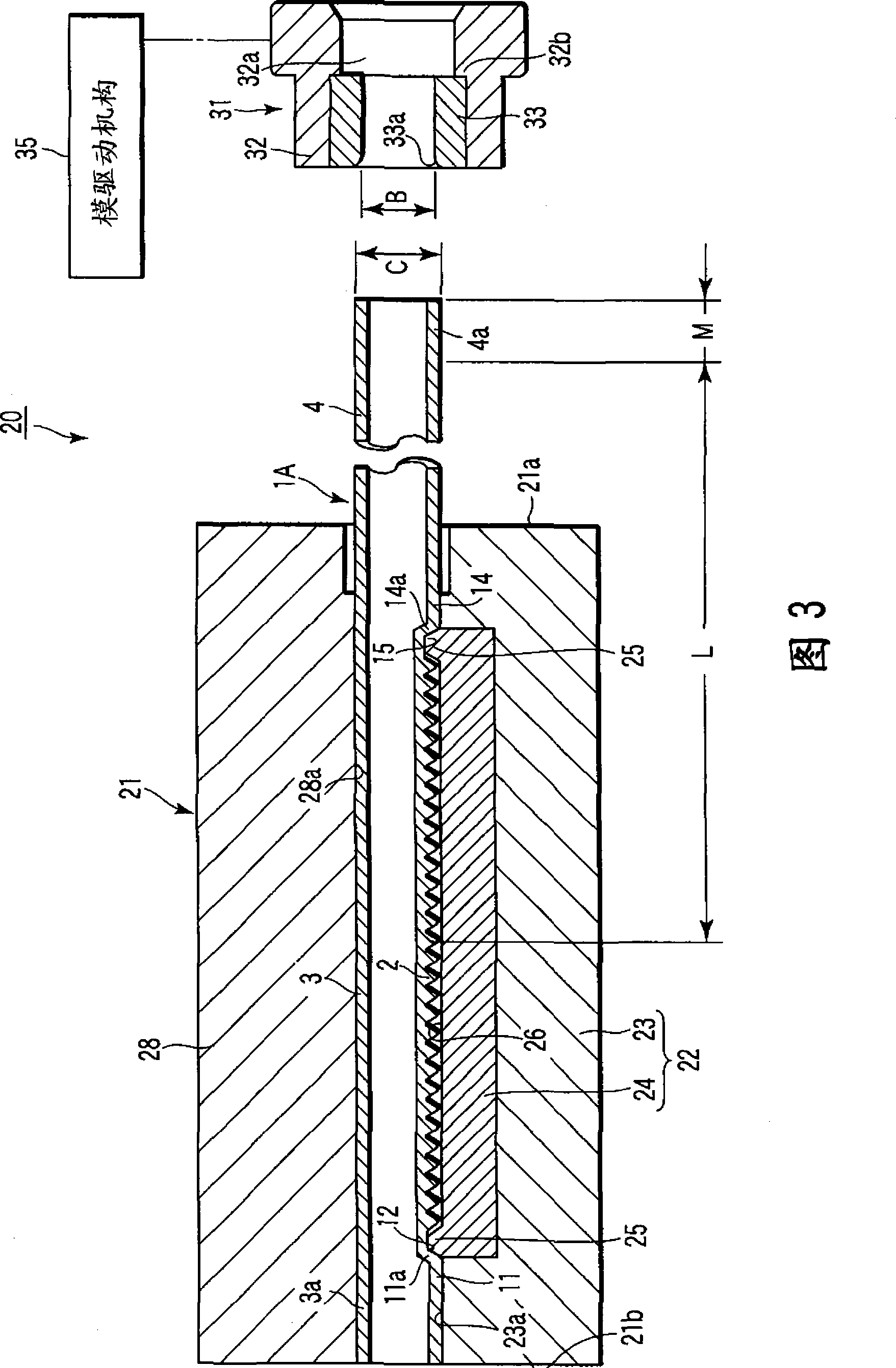

[0068] Figure 1 to Figure 8 It is a figure which shows 1st Embodiment of this invention. figure 1 Reference numeral 1 denotes a hollow rack (hereinafter referred to simply as a rack) used as a hollow steering pinion of an automobile power steering device. Both ends of the rack 1 in the direction in which the central axis extends (hereinafter referred to as the axial direction) are opened respectively.

[0069] A rack 2 is formed on the outer surface of the portion close to the opening at one end of the rack 1 . The rack 2 is formed by arranging a plurality of rack teeth along the axial direction of the rack 1 . The rack 2 is formed on the outer surface of a processed wall portion facing inwardly of the steel pipe so that the material of the rack 1, that is, a part of the pipe wall near the opening at one end of the steel pipe, becomes a flat surface by press working. Press to set. The rack 2 is formed by clamping one end portion of a steel pipe having a processed wall po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com