Skid protection stud and car tire provided with it

An anti-skid pin and pin technology, which is applied to tire parts, tire tread/tread pattern, vehicle parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

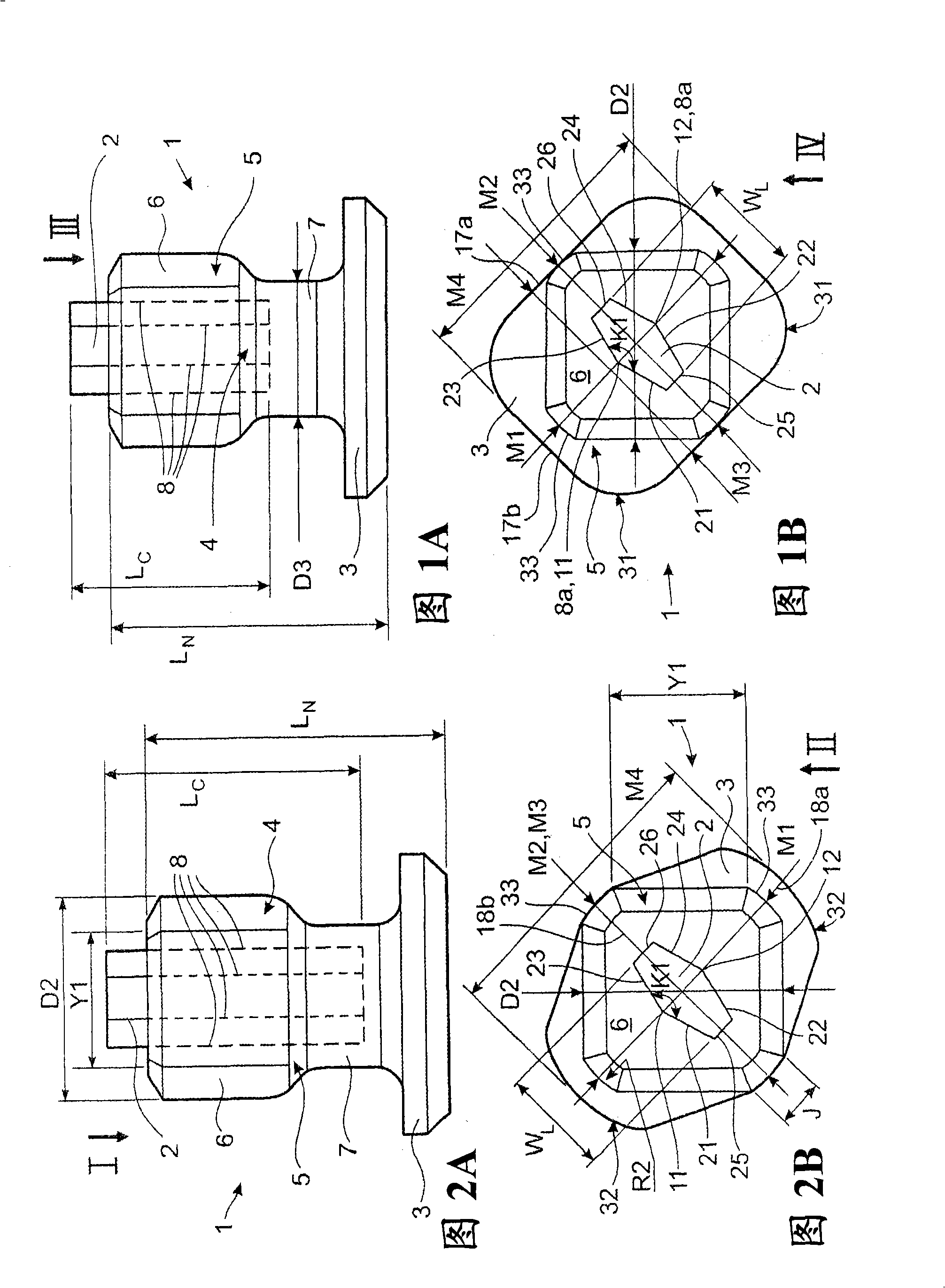

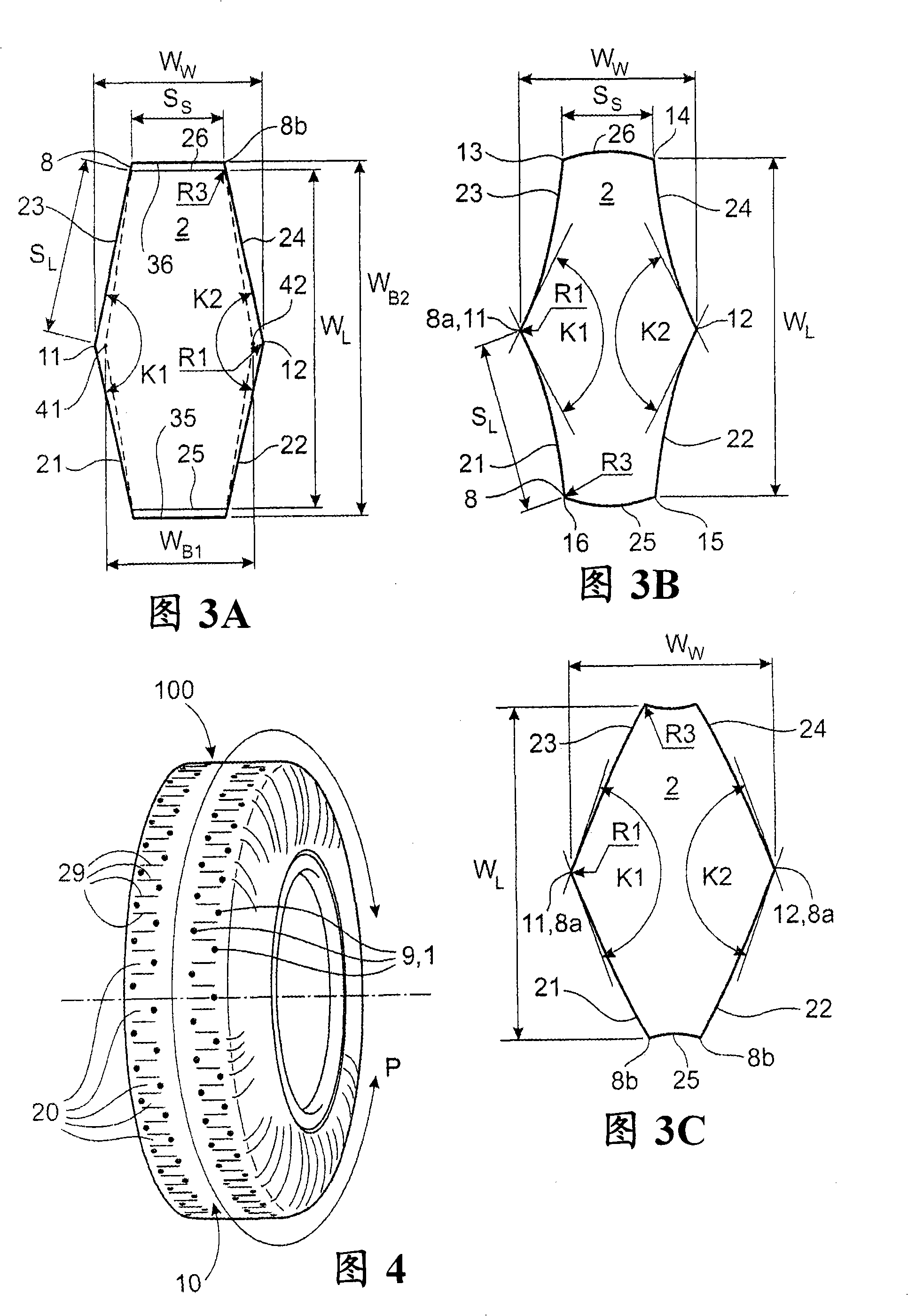

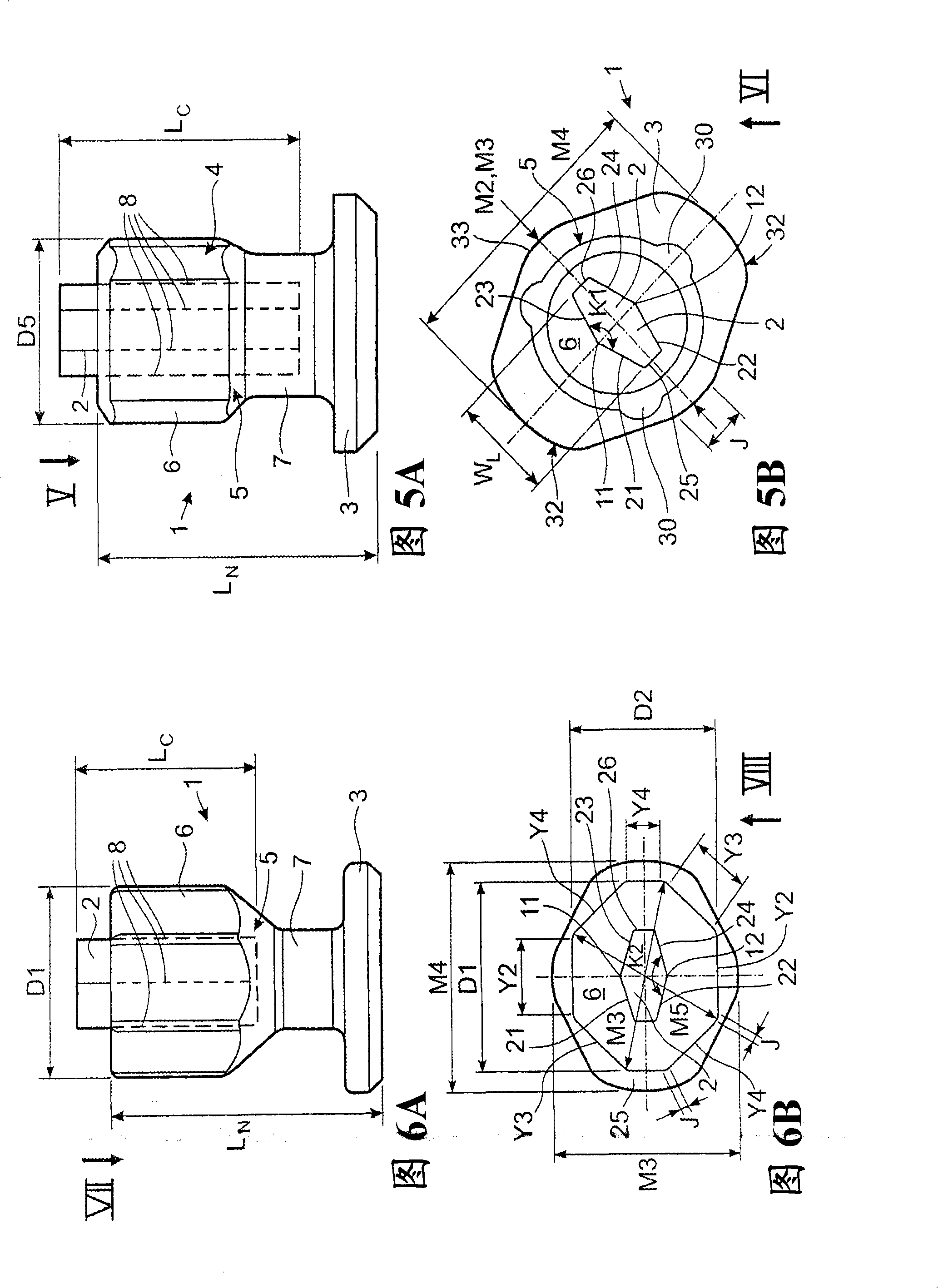

[0014] A vehicle tire 100 has a tread 10 provided with a plurality of at least circumferentially continuous pattern blocks 20 separated by grooves 29 and pin holes 9 prefabricated (i.e. made during a vulcanization process) therein . The cleats are installed after vulcanization in at least some of these pin holes, and generally in all of them, to maintain the intended tire characteristics. The anti-skid pin 1 of solid construction firstly comprises a body 5 made of a first material and presenting a pin length L N , and be provided with bottom plate 3 and rod 4, according to the shape of the rod and especially according to the shape of the upper bowl, the outer diameter of the rod 4 is D1, D2, D3, D4, D5. The body or first material may be steel, any suitable lightweight metal alloy, such as a suitable aluminum alloy, or any suitable type of plastic. The cleat 1 of solid construction also comprises a single elongated hard cermet piece 2 of a second material bonded to the body a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com