Method for processing electric discharge body of ozone generator

An ozone generator and processing method technology, applied in the direction of ozone preparation, etc., can solve the problems of low discharge body efficiency, high damage rate, low output and product qualification rate, etc., and achieve discharge rod reduction, high efficiency, and product qualification rate and the effect of improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

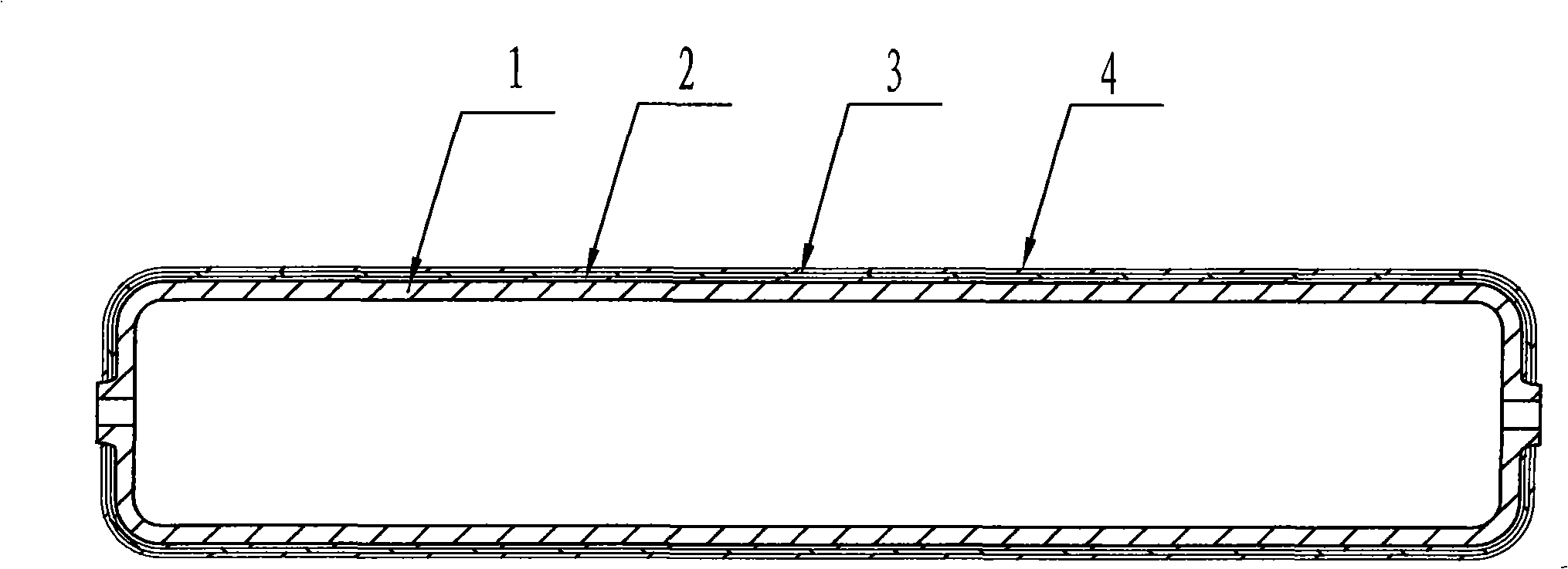

[0055] see figure 1 , An embodiment of the processing method of the discharge body of an ozone generator of the present invention includes the selection of the discharge body blank, the selection of the discharge body glaze, the processing of the tube blank in the discharge body, and the processing of the discharge body blank.

[0056] The blank material of the discharge body is selected from enamel steel, ferritic stainless steel, low carbon, micro carbon and ferritic steel.

[0057] The blank material processing of the inner tube of the discharge body uses a spinning forming process to process the selected blank body into a blank steel pipe with elliptic ends at both ends.

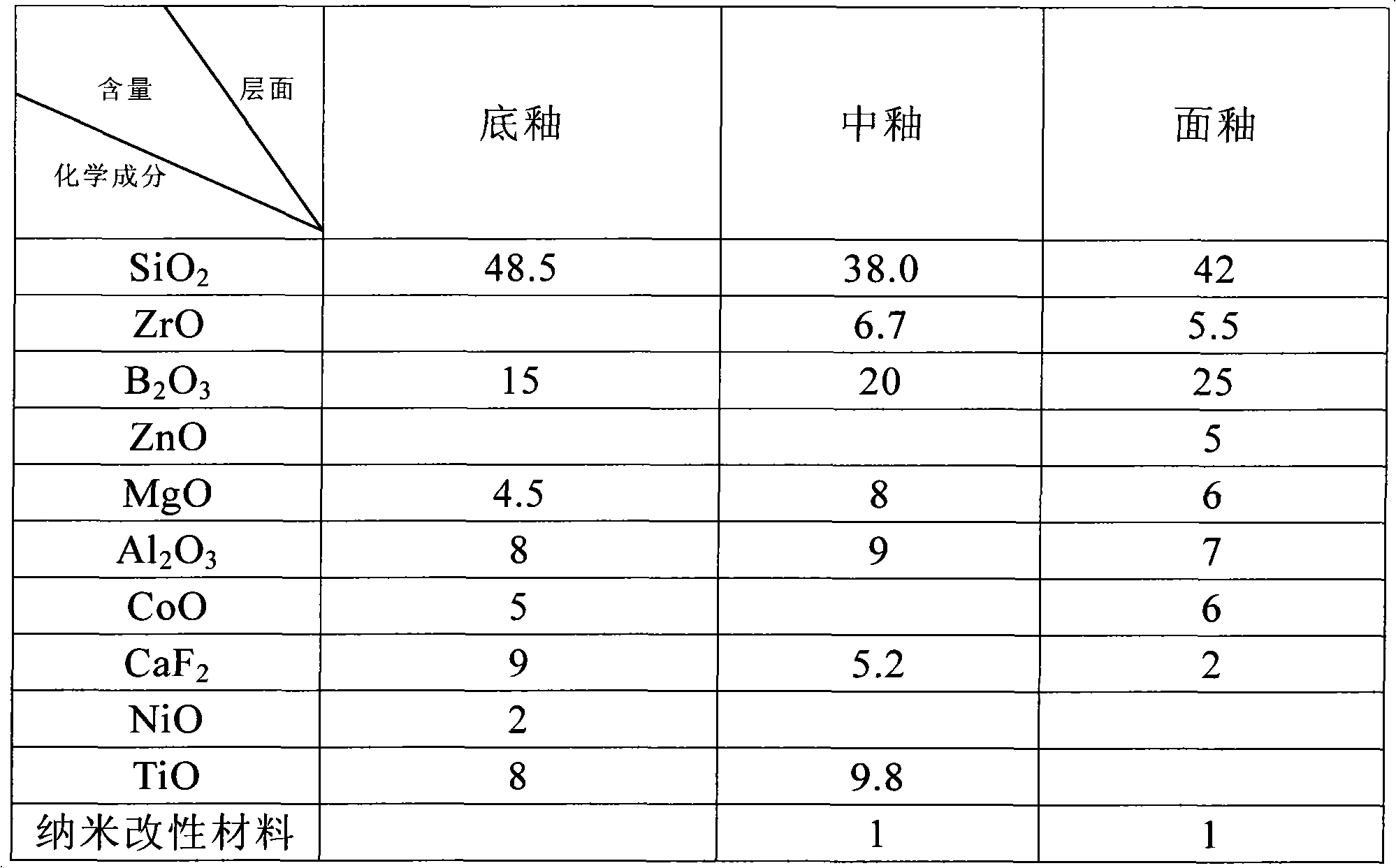

[0058] The processing of the discharge body body: the discharge body body 1 needs to be sprayed with three kinds of enamel media such as bottom glaze 2, middle glaze 3 and top glaze 4 to become a finished discharge body; the specific steps are as follows:

[0059] (1) Sandblasting on the green steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com