Optically detectable, floatable, arsenic- and antimony-free, ceramisable lithium-aluminium-silicate glass

A lithium aluminosilicate, optical detection technology, applied in the field of glass ceramics, can solve problems such as unfavorable enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

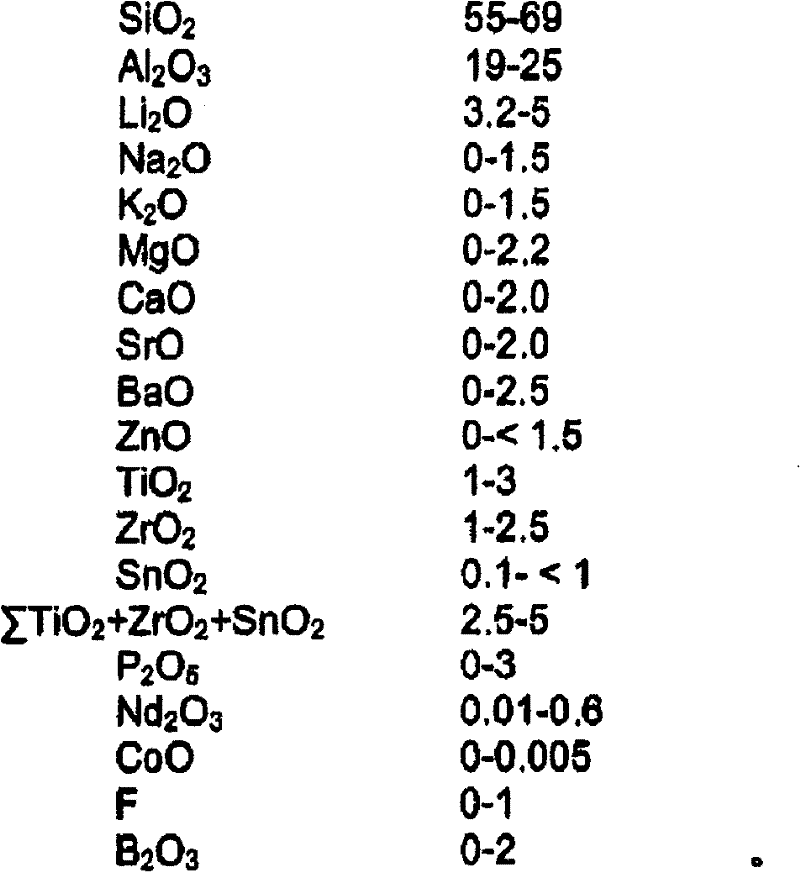

Method used

Image

Examples

Embodiment 2

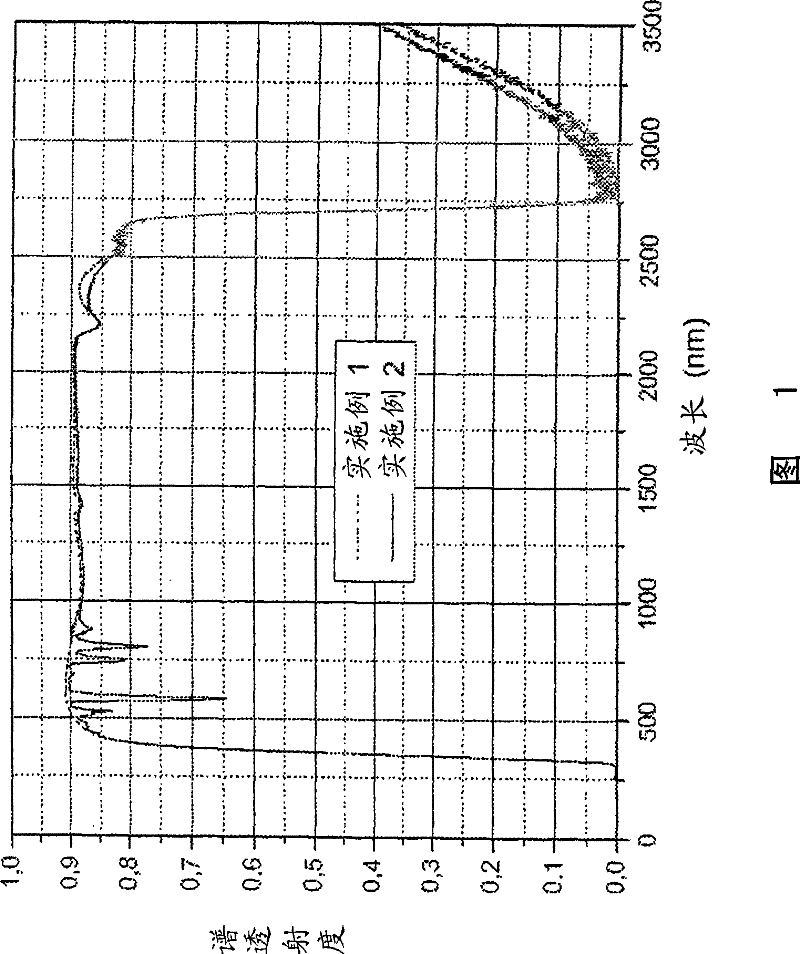

[0074] Example 20 shows the transmission spectrum of 4 mm thick pristine glass (Examples 1, 2). The characteristic absorption band of Nd ions which is particularly suitable for marking and recycling float flat glass according to the invention is seen in Example 2 of the invention.

Embodiment 19

[0079] Glass 2 in Table 1 was chemically prestressed by ion exchange in a sodium nitrate salt bath at 450°C for 22 hours. The thickness of the compressive stress layer is 1 mm, and the polished sample is measured by optical stress measurement before prestressing. The measured surface compressive stress is 7900 nm / cm, and the tensile stress inside the glass is 100 nm / cm. The thickness of the compressive stress region on the surface was 320 μm. The flat glass according to the invention exhibits excellent chemical prestressability due to its relatively high compressive stress values at the surface and the excellent compressive stress layer thickness.

Embodiment 20

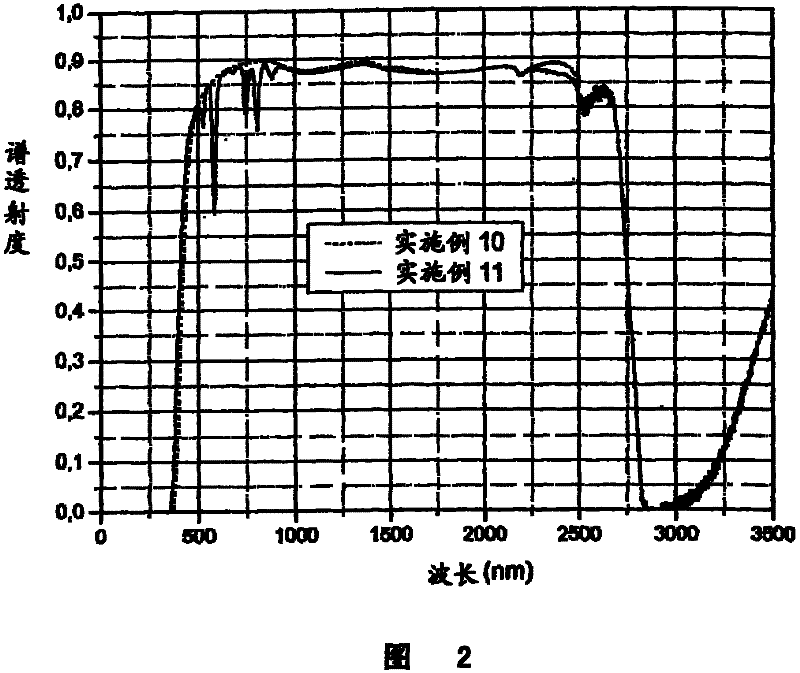

[0080] Example 20 shows a comparison of the transmission spectra of Glass 1 and Glass 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com