Foundation pit guard method for expansion construction from deep foundation pit to shallow foundation pit

A technology for foundation pit enclosure and deep foundation pit, which is applied in foundation structure engineering, excavation, sheet pile wall, etc. The effect of protecting the deformation is small and accelerating the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

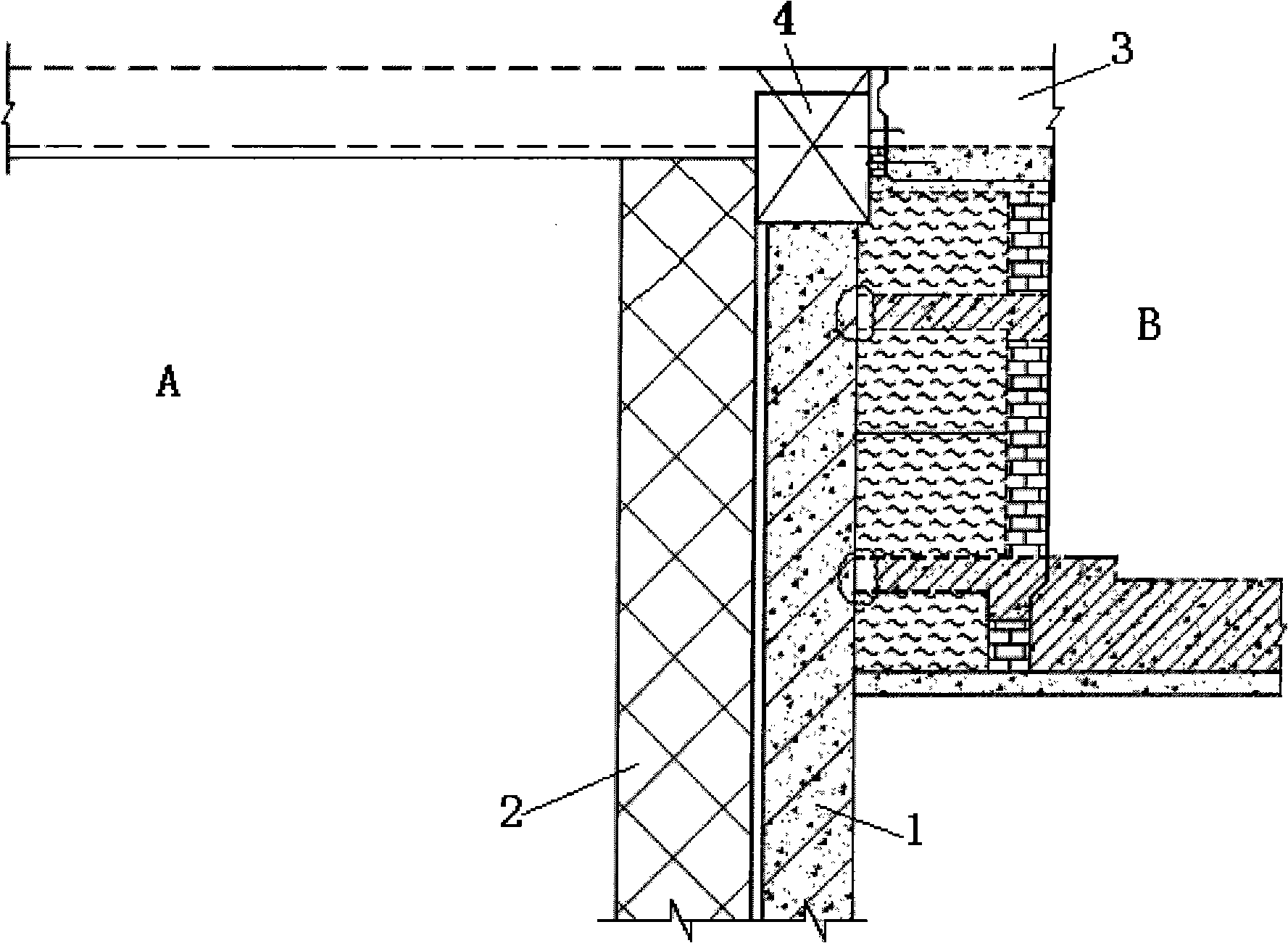

[0014] figure 1 It is a typical junction of deep and shallow foundation pits. Area A in the figure is the deep foundation pit area, and area B is the shallow foundation pit area.

[0015] A kind of foundation pit enclosing method that the deep foundation pit expands construction to shallow foundation pit of the present invention, comprises the following steps:

[0016] (1) At the junction of deep and shallow foundation pits, there is still a gap at the edge of the cap to install bored piles 1, and to install cement mixing water-stop curtains 2 on the outside. The water-stop curtains 2 are close to bored piles 1, and the distance between them should not be greater than 150m .

[0017] (2) For the prestressed pipe piles close to the enclosure structure, C30 plain concrete core filling is carried out, the core filling range is from the top of the first section pile to 1m below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com