Template early-dismantling device

A formwork and roof technology, applied in the field of formwork early dismantling device, can solve the problems of high construction labor intensity, failure to achieve high and low heights, time-consuming and laborious construction, etc., to speed up construction progress and work efficiency, easy installation and disassembly, and reduce material input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

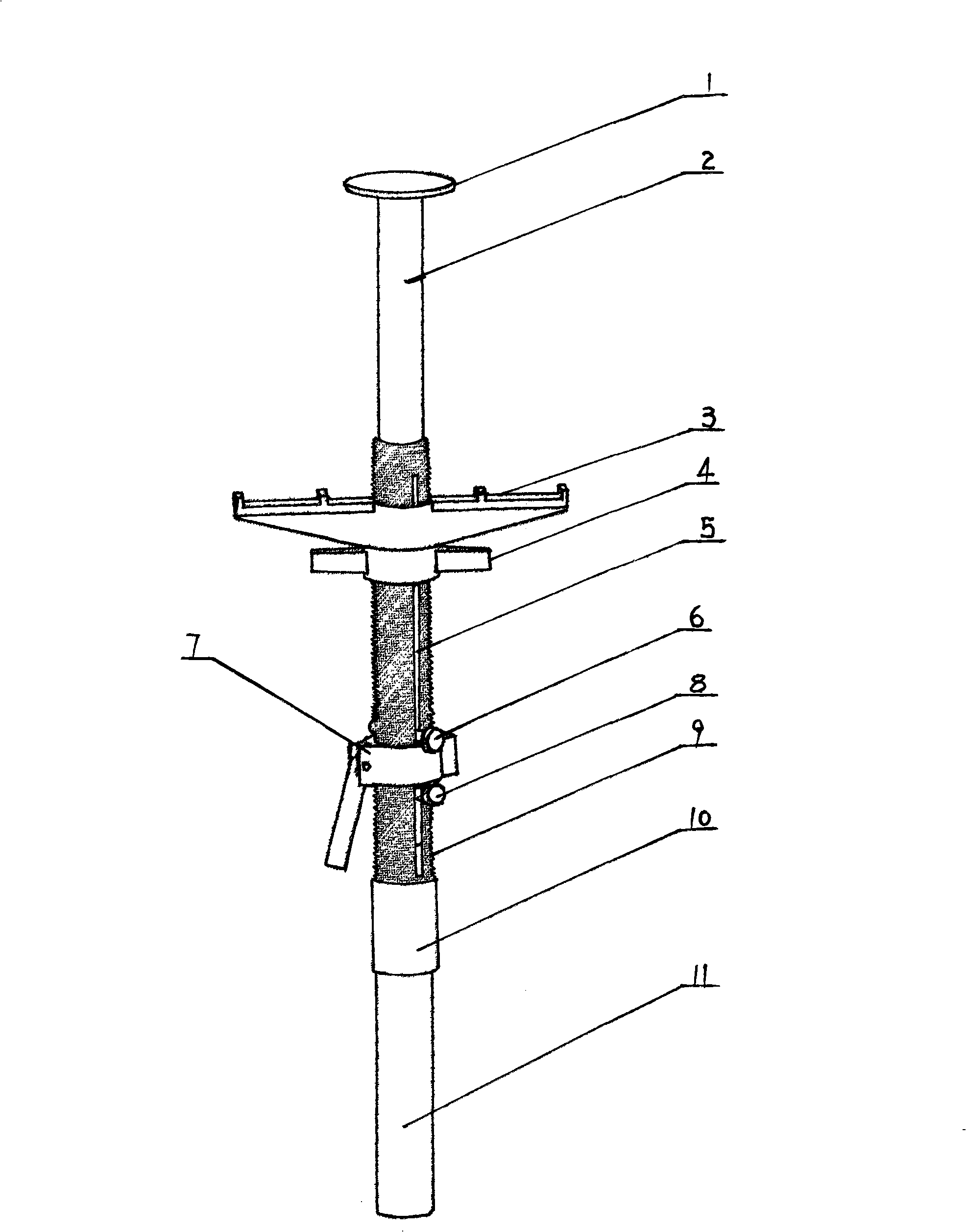

[0020] Such as Figure 1 to Figure 7 As shown, a formwork early removal device is mainly composed of an adjusting threaded pipe, a supporting plate and a supporting plate rod, including the following components:

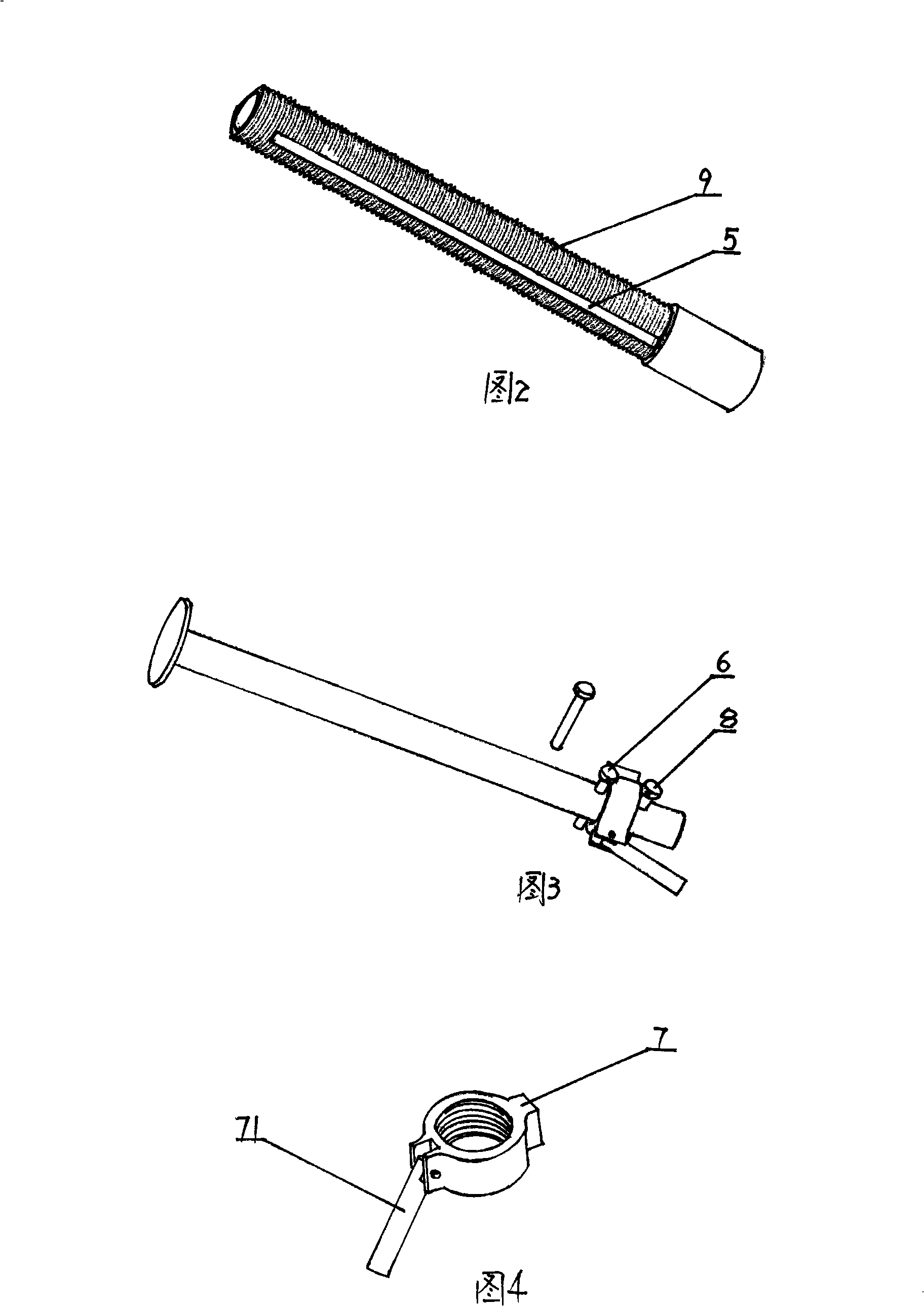

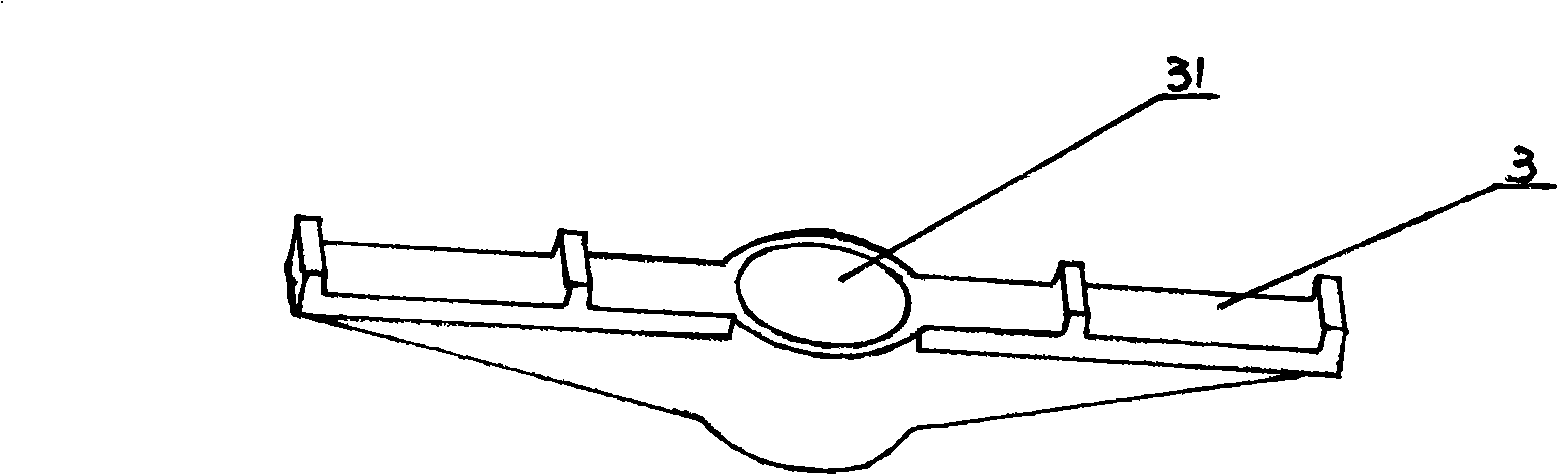

[0021] Adjusting the threaded pipe 9, the outer peripheral wall is an external thread that can be screwed for the bracket adjusting nut 4 and the top plate adjusting nut 7, and the side of the adjusting threaded pipe is provided with a through longitudinal guide groove 5, and the function of the guide groove is for the upper and lower bolts Moving along the guide groove, one end of the adjusting threaded pipe is provided with a socket 10 that can be inserted into the scaffolding pipe, and the external thread part is provided with a bracket 3, a bracket adjusting nut, an upper latch 6 and a top plate adjusting nut in sequence from top to bottom.

[0022] The supporting plate rod 2 is tubular, one end of which is inserted in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com