Internal coating continuous pipe with cooling trough flange and its connection method

A cooling tank and flange technology, applied in flange connections, non-detachable pipe connections, coatings, etc., can solve the problems of preferential corrosion, lack of effective equipment and methods for post-weld internal repair, leakage and shutdown, etc. The effect of ensuring integrity, avoiding damage, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Material preparation

[0057] (1) Select two sections of seamless steel pipe with a specification of Φ133×5 as the main pipe, and the surface of the butt joint of the two main pipes is processed into a bevel.

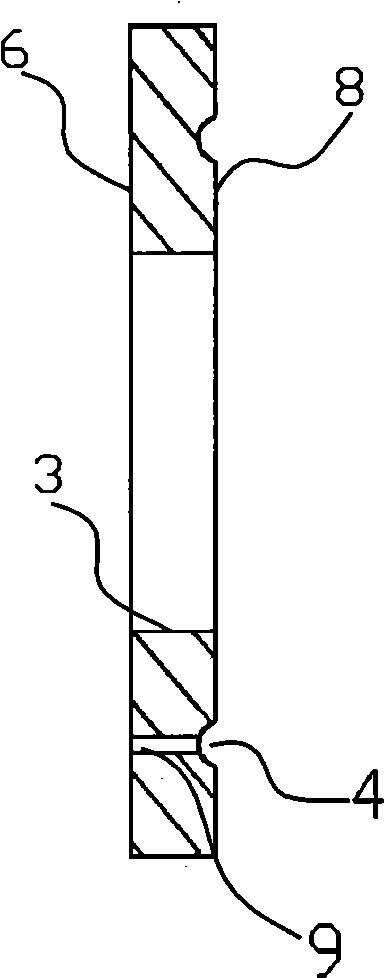

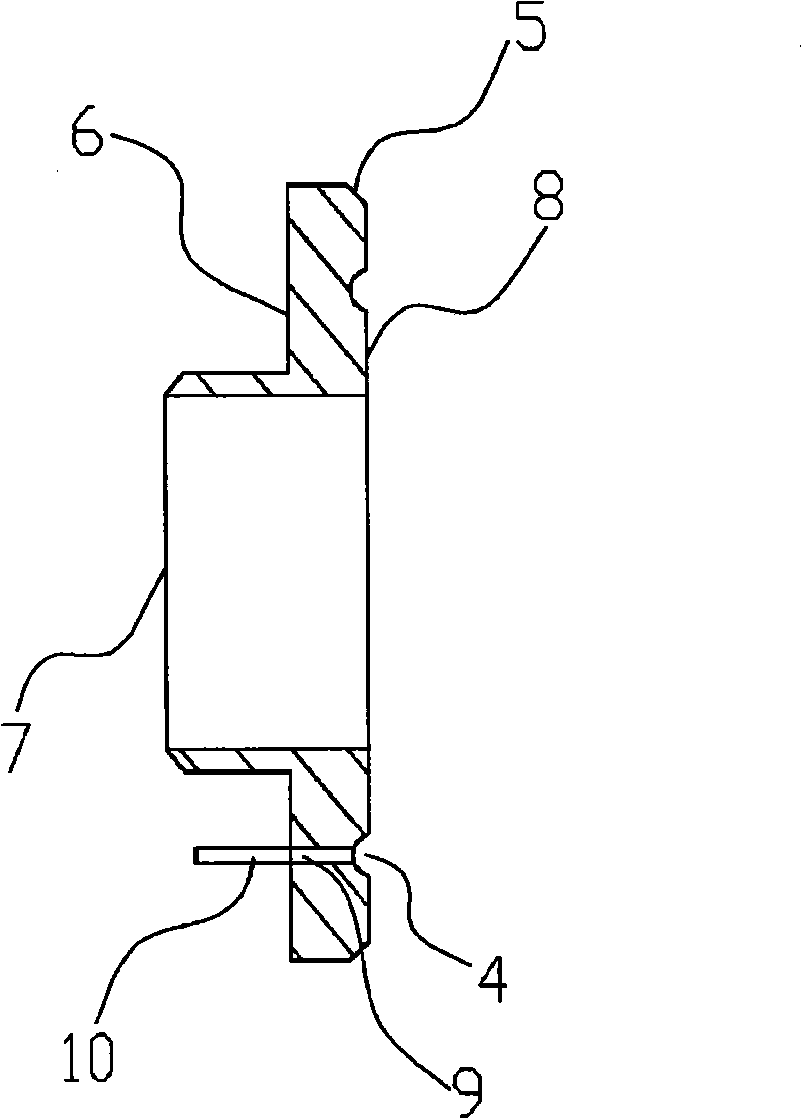

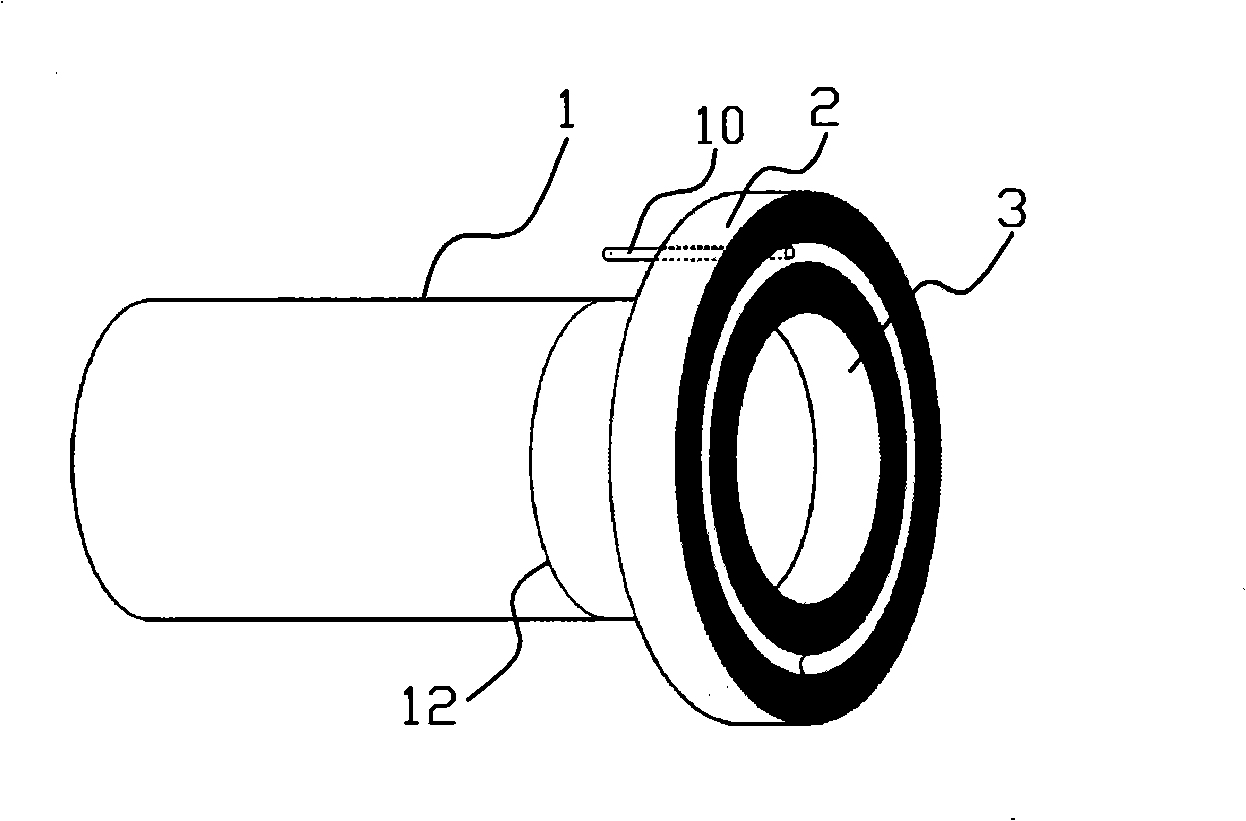

[0058] (2) if figure 2 As shown, make two identical butt weld neck flanges, the inner diameter of the flange is 123mm, the outer diameter is 250mm, and the flange thickness is 50mm. A bevel 5 is provided on the outer edge of the flange sealing surface 8 . The length of the neck pipe 7 of the flange is 100mm, the wall thickness of the neck pipe of the flange is 5mm, and the end of the neck pipe is provided with a bevel. The flange sealing surface 8 is planar. An annular cooling groove 4 is opened on the flange sealing surface 8, and its cross-sectional shape is semicircular. The cooling groove is 12mm wide and 6mm deep. The diameter of the cooling hole 9 connecting the cooling groove 4 and the flange back 6 is 4 mm. Weld a cooling pipe 10 with a length o...

Embodiment 2

[0077] see Figure 5 , This embodiment uses the flange of the present invention whose sealing surface is a concave-convex surface, and other parameters and operations are the same as in Embodiment 1. The advantage of this solution is that the main tube sealing ability is improved.

Embodiment 3

[0079] see Figure 6 , This embodiment uses the flange of the present invention whose sealing surface is a tongue-and-groove surface, and other parameters and operations are the same as in Embodiment 1. The advantage of this scheme is that the quality of the flange joint structure assembly is improved, and the sealing ability of the main pipe is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com