Process for producing latent catalyst and epoxy resin composition

一种制造方法、潜伏性的技术,应用在化学仪器和方法、物理/化学过程催化剂、有机化合物/氢化物/配位配合物催化剂等方向,能够解决难以获得高产率高纯度等问题,达到优异流动性的效果

Active Publication Date: 2011-01-19

SUMITOMO BAKELITE CO LTD

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This makes it difficult to obtain high-yield and high-purity target product phosphonium silicate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

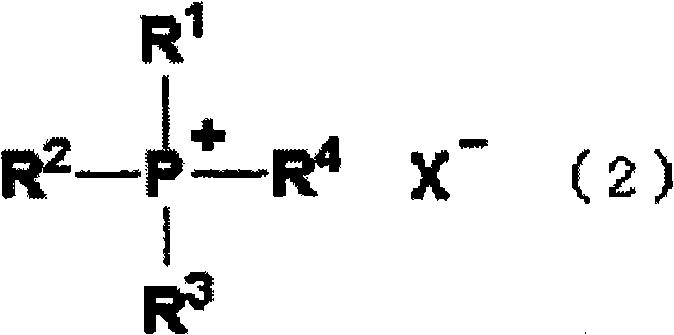

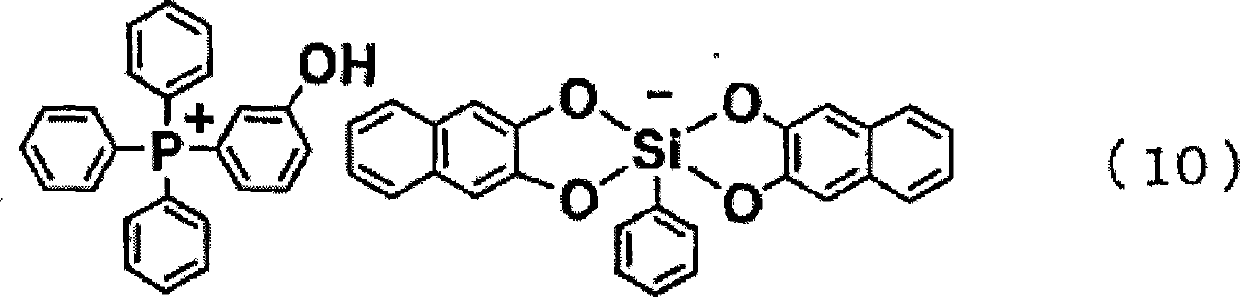

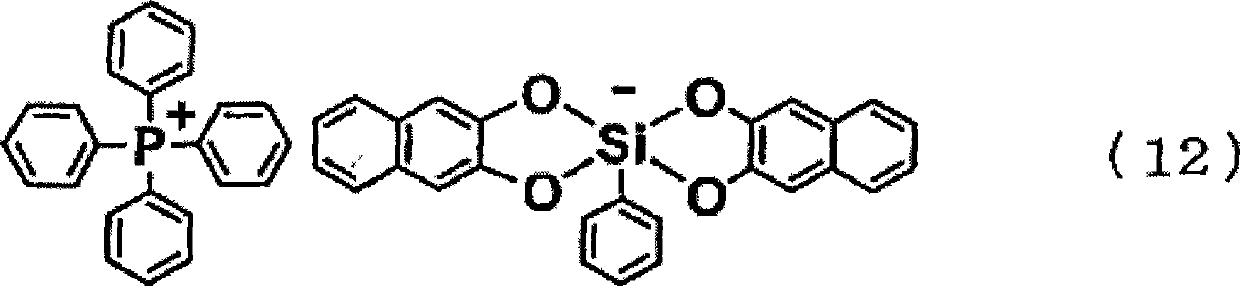

A process for producing a latent phosphonium silicate catalyst, characterized by reacting a proton donor (A) represented by the general formula (1), a trialkoxysilane compound (B), and a phosphonium salt compound (D) represented by the general formula (2) in the presence of a metal alkoxide compound (C).

Description

Technical field The invention relates to a method for manufacturing a latent catalyst, and also relates to an epoxy resin composition. Background technique As a method of encapsulating semiconductor devices (such as IC and LSI) to manufacture semiconductor devices, due to low cost and suitability for mass production, transfer molding methods using epoxy resin compositions are widely used. The characteristics and reliability of semiconductor devices are improved by improving epoxy resins or phenol resins as curing agents. However, with the current market trend toward small-size, light-weight, and high-performance electronic devices, the integration degree of semiconductors used in such devices has increased year by year, and the surface assembly of semiconductor devices has been promoted. In this case, there are very strict requirements for the epoxy resin composition used to encapsulate the semiconductor chip. So there are some problems that cannot be solved by traditional ep...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G59/68

CPCC08G59/688C08G59/68B01J31/00

Inventor 乡义幸

Owner SUMITOMO BAKELITE CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com