Double bottom cultivating pool of breeding blue crab

A technology of cultivation pond and double bottom, applied in the field of cultivation pond, can solve the problems of bacterial reproduction, time-consuming, disturbing breeding crabs, etc., and achieve the effects of increasing the survival rate of cultivation, increasing the proportion of gain, and improving the conditions of oxygen supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

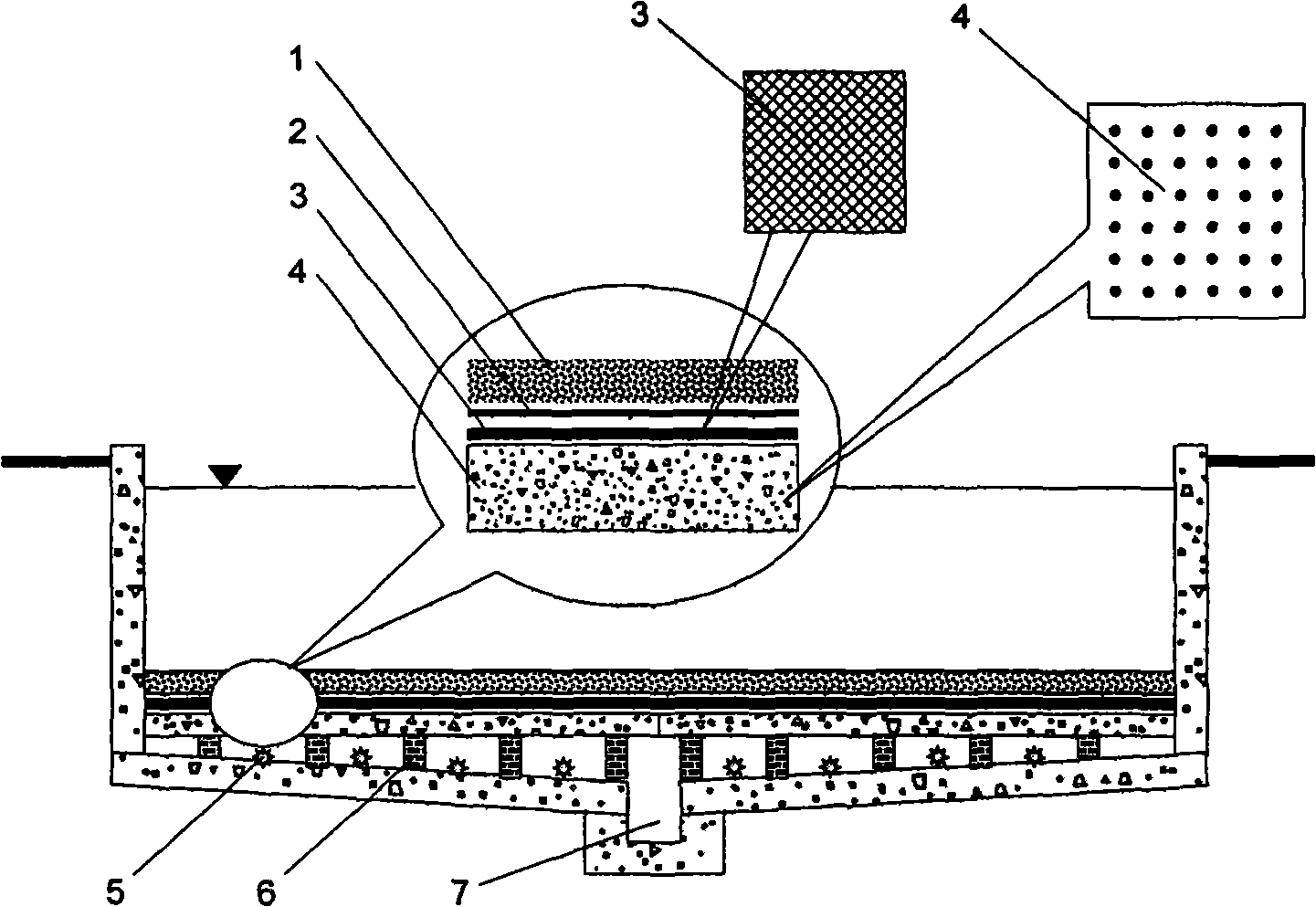

[0009] The bottom of the cultivation pond adopted by the present invention is provided with a drain outlet 7, and a layer of dividing plate 4 is added at a height of 10 cm from the bottom of the cultivation pond. The dividing plate 4 preferably adopts a cement dividing plate with a thickness of 6 cm to 8 cm. There are strip-shaped beams or block support bodies 6, and through-holes with a diameter of 3 cm to 5 cm are arranged on the surface of the cement partition 4 at a distance of 30 cm. Two layers of nets are laid on the top of the cement partition, and the lower layer (the net next to the partition 4) is The hard PVC net 3 of mesh size 20mm, the upper layer (the net stacked on the upper side of the hard PVC net 3) is a 60 order / square inch nylon screen 2, and the effect of the nylon screen 2 is mainly to prevent the loss of sea sand, so Its four sides are higher than the sea sand layer, which has a good effect. The sea sand 1 with a particle size of 0.074 mm to 0.106 mm is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com