Dried-to-raisin grapes washing device

A flushing device and raisin technology, which can be used in applications, food processing, food science, etc., and can solve problems such as sticking dust, pollution, and high labor intensity for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

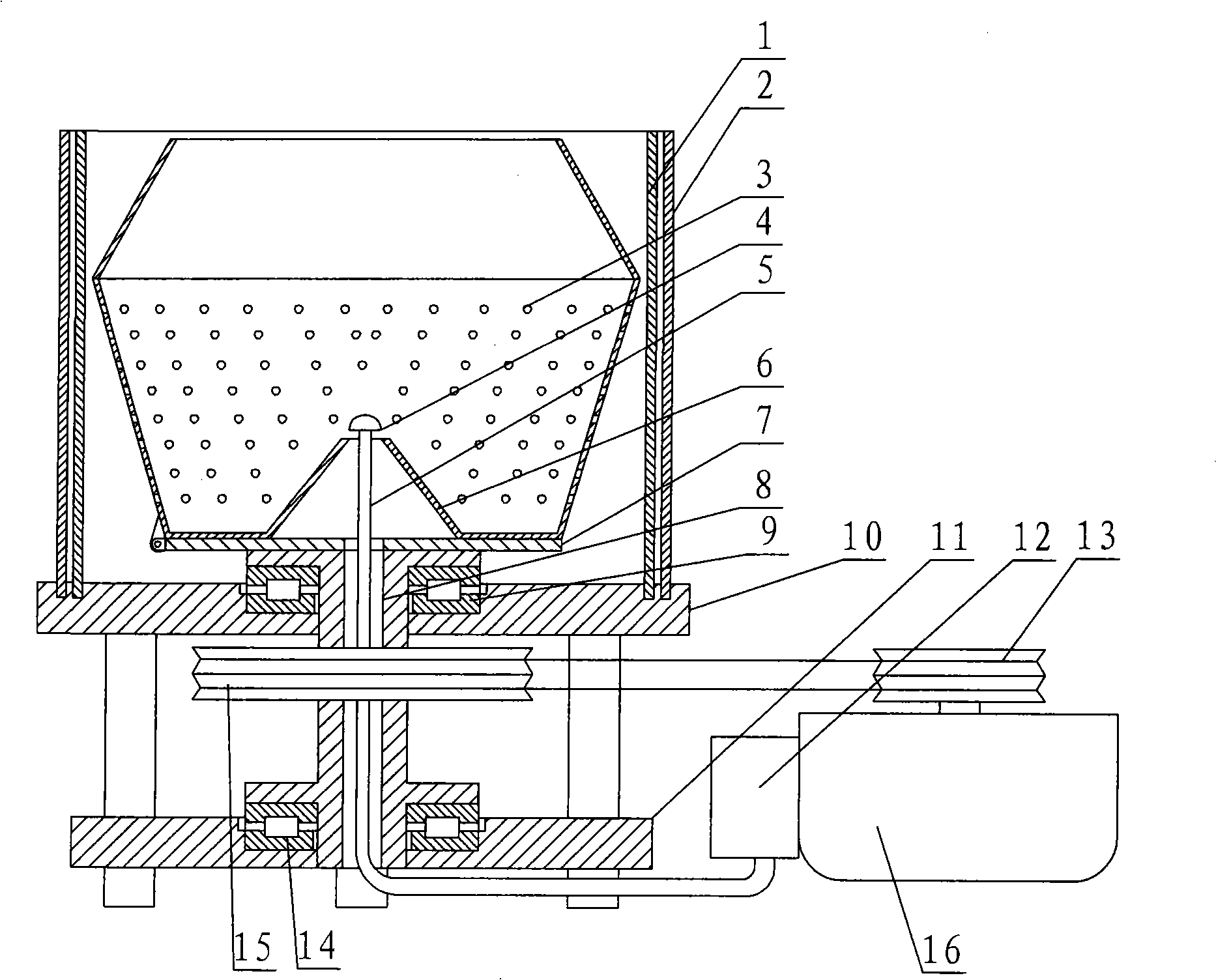

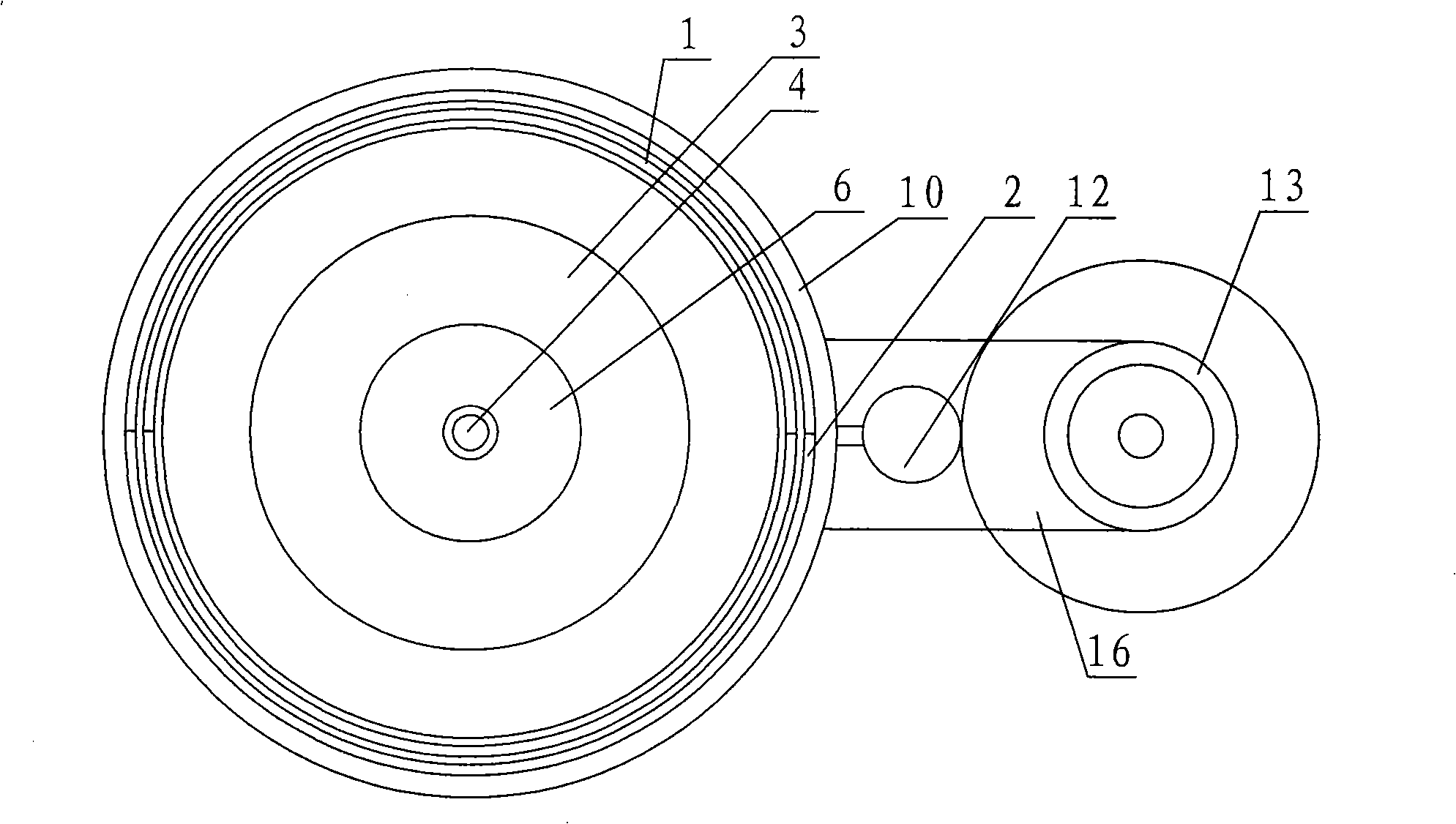

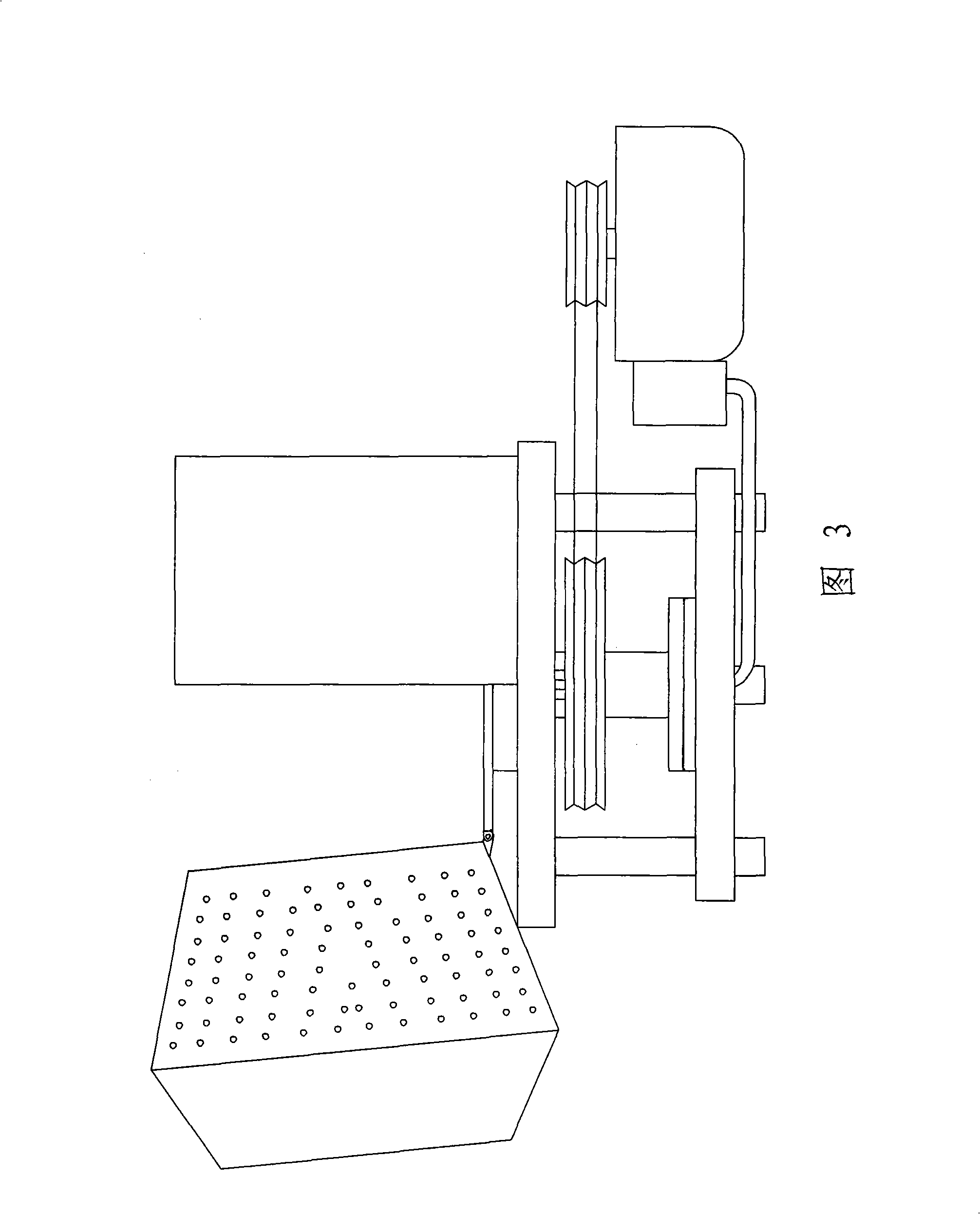

[0010] A raisin washing device, such as figure 1 , figure 2 , shown in Fig. 3, comprise frame and motor 16, upper and lower parts of the frame are respectively provided with upper and lower bases 10,11 horizontally, and upper and lower bases 10,11 centers are respectively provided with upper and lower thrust bearings 9, 14, upper and lower thrust bearings 9 and 14 are thrust roller bearings. A hollow main shaft 8 is vertically arranged between the upper and lower thrust bearings 9 and 14, the middle part of the main shaft 8 is fixedly connected with the driven transmission wheel 15 driven by the motor 16, and the rotating shaft of the motor 16 is fixedly connected with the driving transmission wheel 13. Wheel 13 is connected with driven transmission wheel 15 by belt. The electric motor 16 is a variable-frequency speed-regulating electric motor, so that its rotating speed can be adjusted conveniently and realizes positive and negative rotation control. The top of the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com