Anti-loose mechanism for locking knife tool used in cutting machine

A cutting machine, anti-loosening technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of reduced tool locking reliability, increased thread fit clearance, hidden safety hazards, etc., to reduce thread clearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

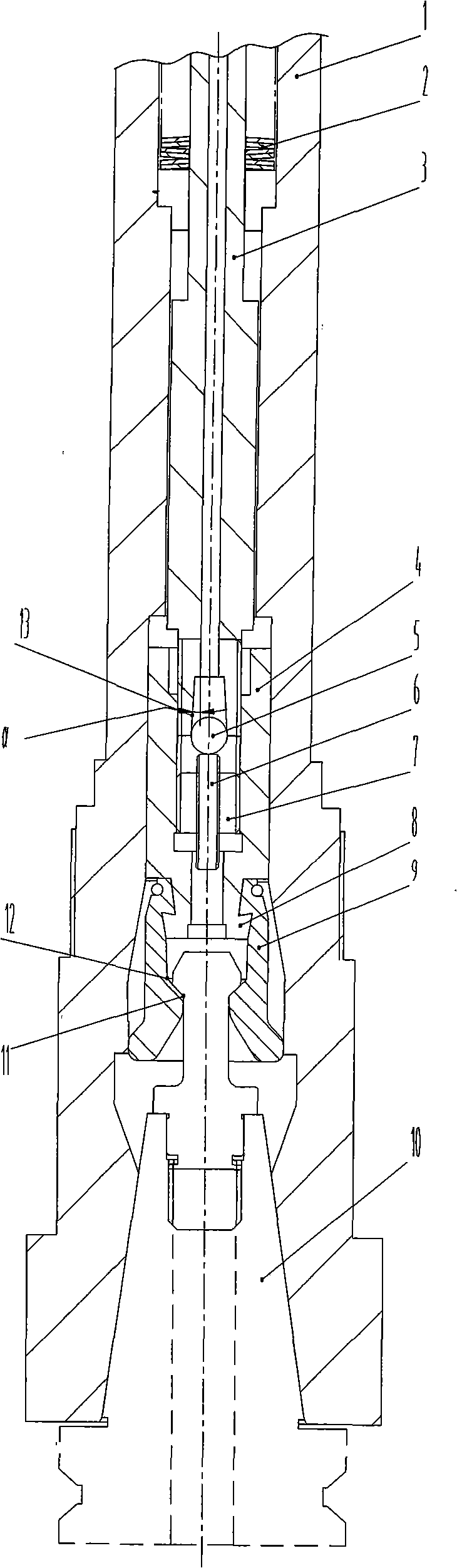

[0012] As shown in the figure, the present invention includes a butterfly spring 2, a pull rod 3, a sliding sleeve 4, a knife claw 9, and a handle 10 arranged in sequence in the machine tool spindle 1. One end of the pull rod is connected to the butterfly spring 2, and the other end is threaded. Connect the sliding sleeve 4, the other end of the sliding sleeve 4 is hooked with the broach claw 9 through the hook teeth 8 on the outer edge, and the handle 10 is snapped on the inside of the broach claw 9 through the boss 11 at the end. Inside the broach claw, a cylindrical taper hole 13 with a large diameter facing outward is provided at the end of the pull rod 3 connected to the sliding sleeve 4. The taper hole is equipped with a steel ball 5 tangent to the taper hole, and a top-facing The anti-loosening screw 6 of the steel ball, the anti-loosening screw 6 is assembled in the anti-loosening nut seat 7, and the anti-loosening nut seat 7 is installed in the inner cavity of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com