Lubricating oil composition and lubricating system using the composition

A technology of lubricant composition and lubrication system, which is applied in the direction of lubrication composition, additives, petroleum industry, etc., can solve the problems of polluting the surrounding area, prolonging the life of the leakage mechanical system, and inability to exert initial performance, etc., and achieve high dynamic friction coefficient, high Effects of Extreme Pressure and Coefficient of Kinetic Friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

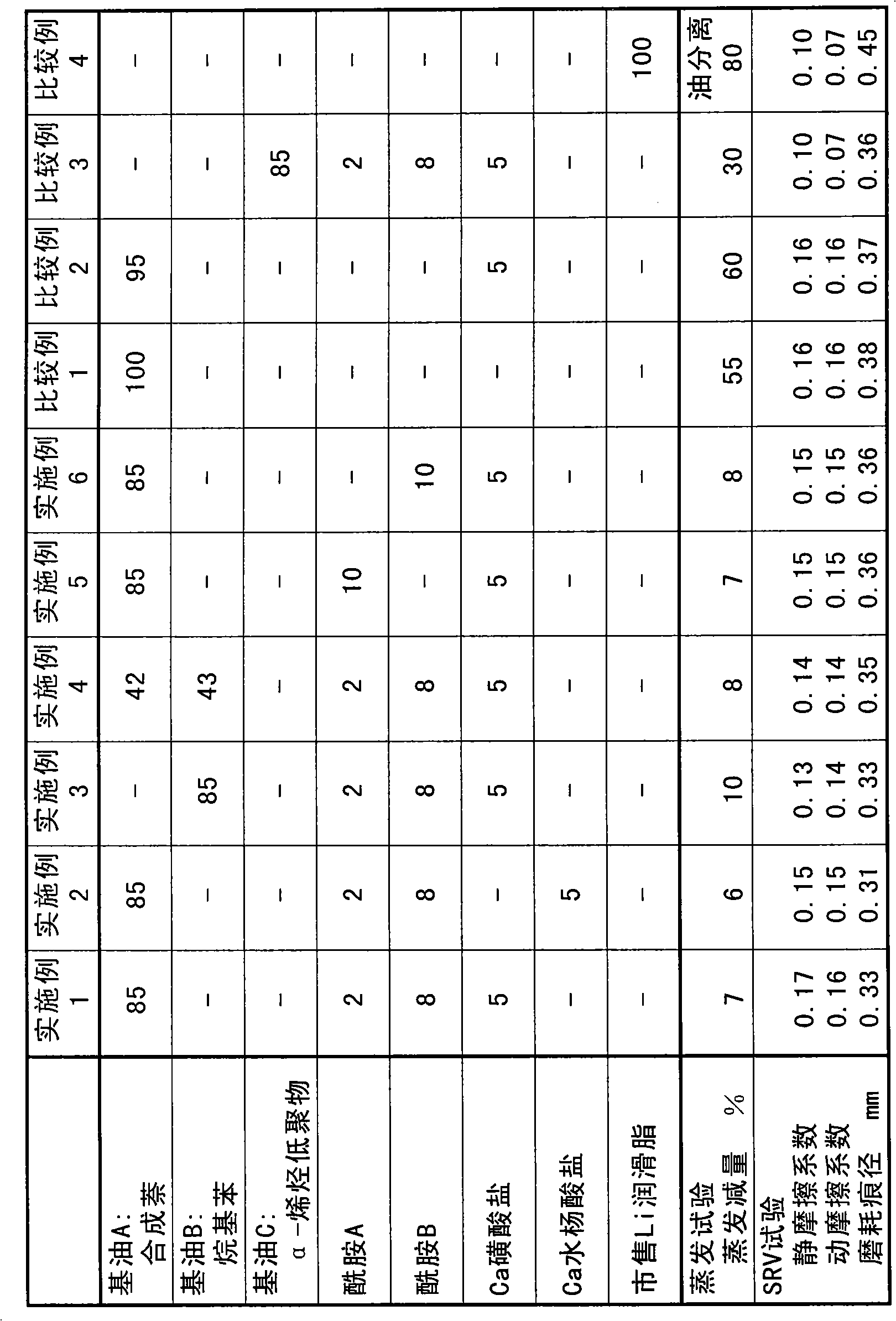

[0058] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited thereto.

[0059] [Liquid base oil]

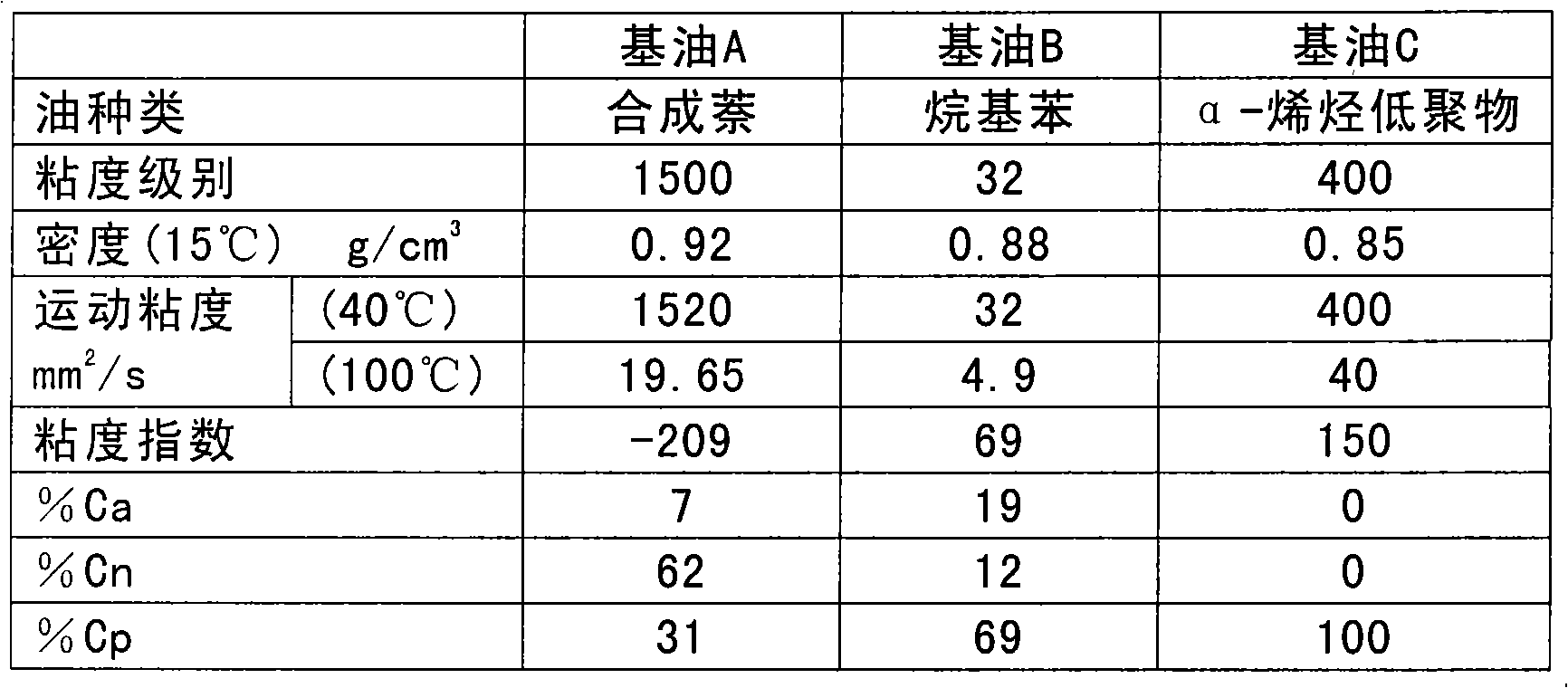

[0060] In order to prepare the lubricant compositions used in Examples and Comparative Examples, the following three types of liquid base oils were used.

[0061] Base oil A: Synthetic naphthalene (Techtrac M3Conc manufactured by Techchem Corporation)

[0062]Base oil B: soft alkylbenzene (kinematic viscosity (40°C): 32mm 2 / s)

[0063] Base oil C: α-olefin oligomer (SHF-400 manufactured by Mobil Corporation)

[0064] Table 1 shows the physical properties of these three liquid base oils. In addition, these liquid lubricating base oils contain predetermined amounts of additives such as antioxidants and anti-wear agents in advance, and have basic properties (anti-oxidation, anti-wear, etc.) as lubricating oils.

[0065] [Table 1]

[0066]

[0067] [amide compound]

[0068] In order to mix with liquid b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Total base number | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com