Temperature distribution measuring method for high speed rotating permanent magnetism synchronous electric machine rotor

A technology of permanent magnet synchronous motor and measurement method, applied in radiation pyrometry, measurement device, optical radiation measurement, etc., can solve problems such as difficulty in ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A three-phase permanent magnet synchronous motor with a rated power of 30kW, a rated voltage of 380V, a rated current of 49.5A and a rated speed of 1500r / min was selected as the measurement object. The infrared temperature sensor used for control and temperature measurement is the μIRt / c infrared temperature sensor produced by EXERGEN Company, and its response frequency is 20Hz.

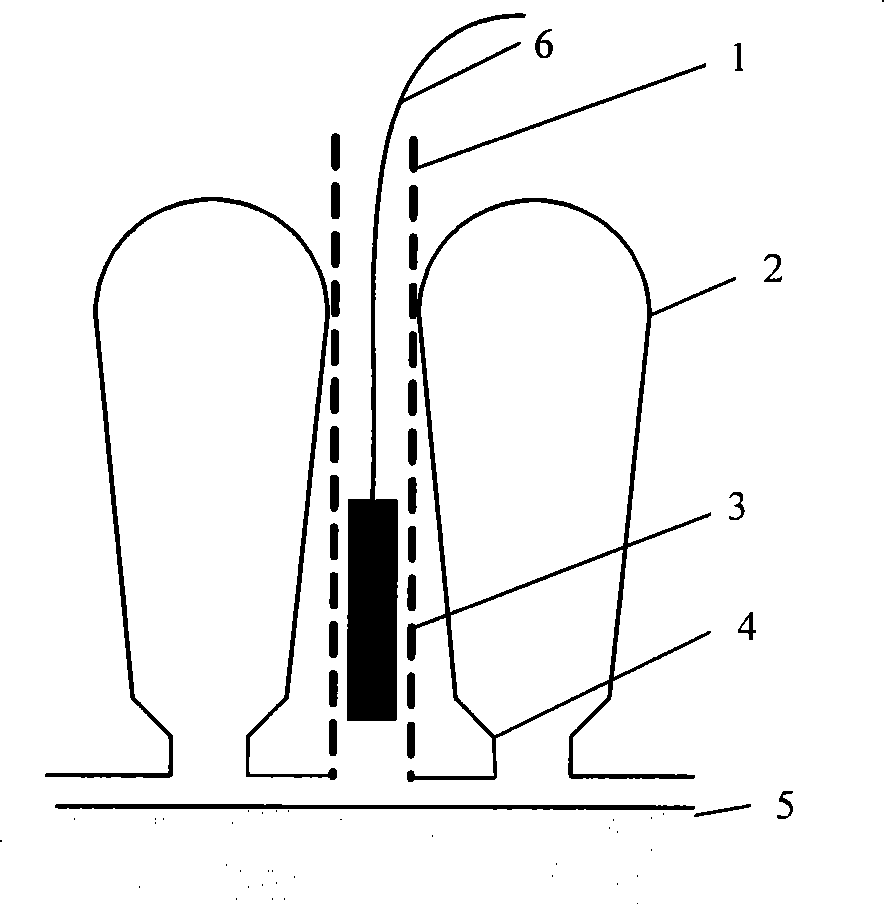

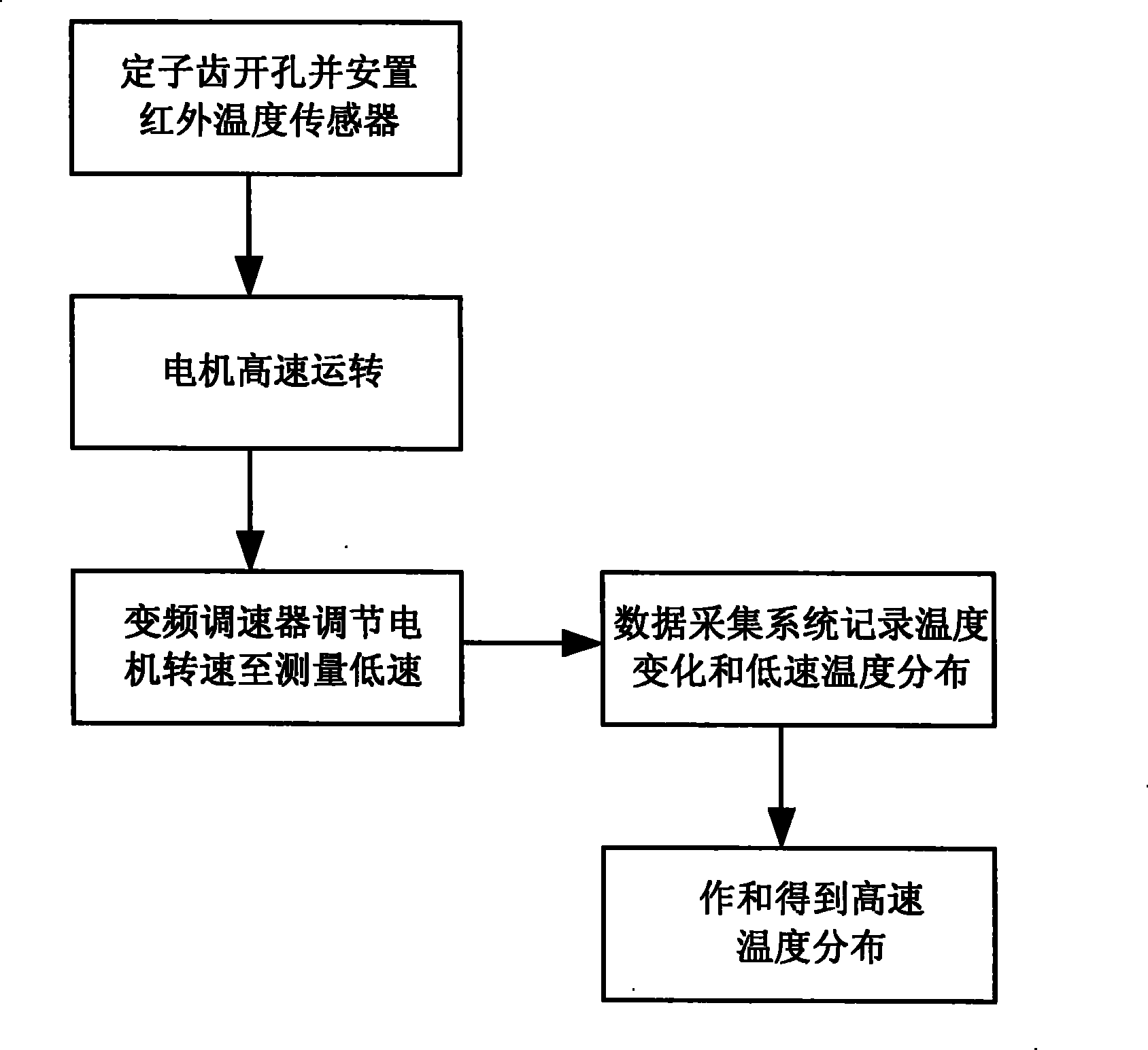

[0025] A hole is opened on a stator tooth of a permanent magnet synchronous motor, and a μIRt / c infrared temperature sensor is placed in the hole so that the sensor probe is directly opposite to the surface of the permanent magnet rotor. The output end of the μIRt / c infrared temperature sensor is connected to the data acquisition system. The data acquisition system in this embodiment consists of a data acquisition card and a computer.

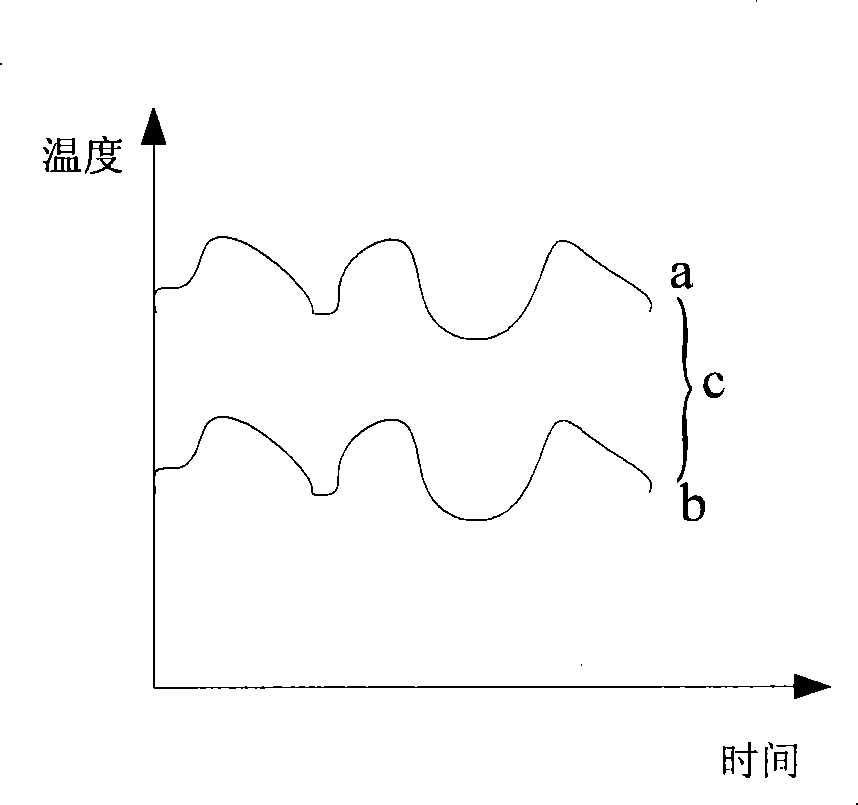

[0026] Now measure the temperature distribution of the rotor surface of the permanent magnet synchronous motor after running for 2 hours at the rated speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com