Hot-wire anemometer calibration apparatus and method in acoustic field

A technology of hot wire anemometer and calibration device, which is applied in the direction of electric power measurement and series vibration meter by thermal method, which can solve the problems of limiting the calibration range, increasing the difficulty and uncertainty of calibration, and achieving a large speed range and accurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

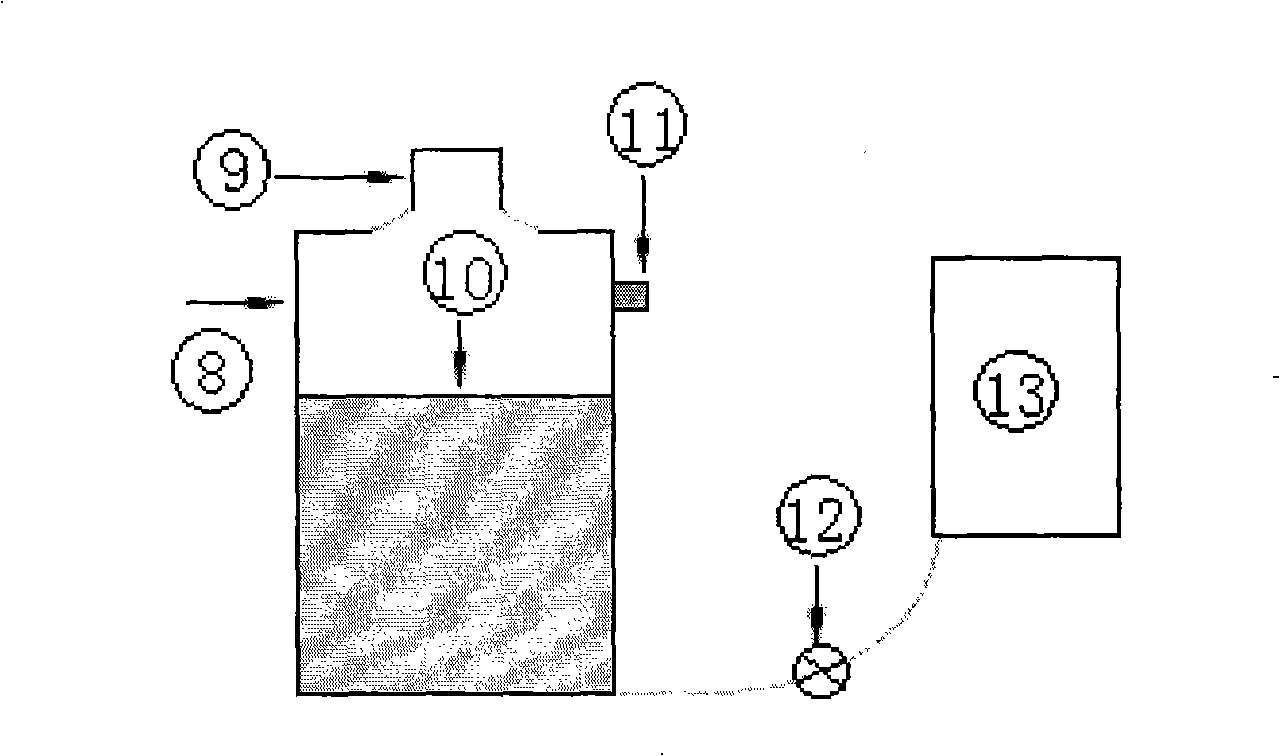

[0043] Such as Figure 4 As shown, the hot wire anemometer in the sound field of the present invention is a device using a moving probe calibration method, mainly comprising: a pressure-bearing airtight container 14 with a fluid working medium input valve and an output valve; The hot-wire probe 4 of the hot-wire anemometer is a driving device 16 that moves in the airtight container, and the driving device 16 fixes and drives the probe 4 to move through a guide rod device 15 thereon; it is used to sense the reciprocating motion of the probe 4 The displacement sensor installed on the driving device for speed; the pressure sensor and temperature sensor installed on the airtight container to measure the pressure and temperature of the working medium in the airtight container.

[0044] In addition to designing the size of the airtight container 14 according to the volume of the parts placed in the container, it is also necessary to take into account the disturbance of the moving pa...

Embodiment 2

[0051] Such as Figure 5 As shown, the hot-wire anemometer in the sound field of the present invention is a device using a moving probe calibration method, which is different from Embodiment 1 in that: Figure 5 As shown, the present embodiment is semi-closed, and the driving device 16 is placed outside the sealed container 14, and the hot wire probe 4 is placed in the sealed cavity 14 through the guide rod 15. Dynamic sealing is performed, for example, by means of a dynamic sealing mechanism 18 . The advantage of the semi-closed type is that the moving parts in the closed chamber are only the probe and the guide rod device, so the volume is small, but the requirements for dynamic sealing are increased, and when the container is filled with high pressure, the drive mechanism is increased. differential pressure load. In Embodiments 1 and 2, both the pressure sensor and the temperature sensor can be installed on the wall of the airtight container. Others are the same as embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com