Novel structure gas barbecue stove

A barbecue stove and a technology with a new structure, which are applied in the directions of burners, combustion methods, and the combination of multiple burners, can solve the problems of poor barbecue effect, waste of gas resources, unreasonable structure, etc., and achieve convenient ignition and start, The effect of reducing heat loss and increasing the temperature in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

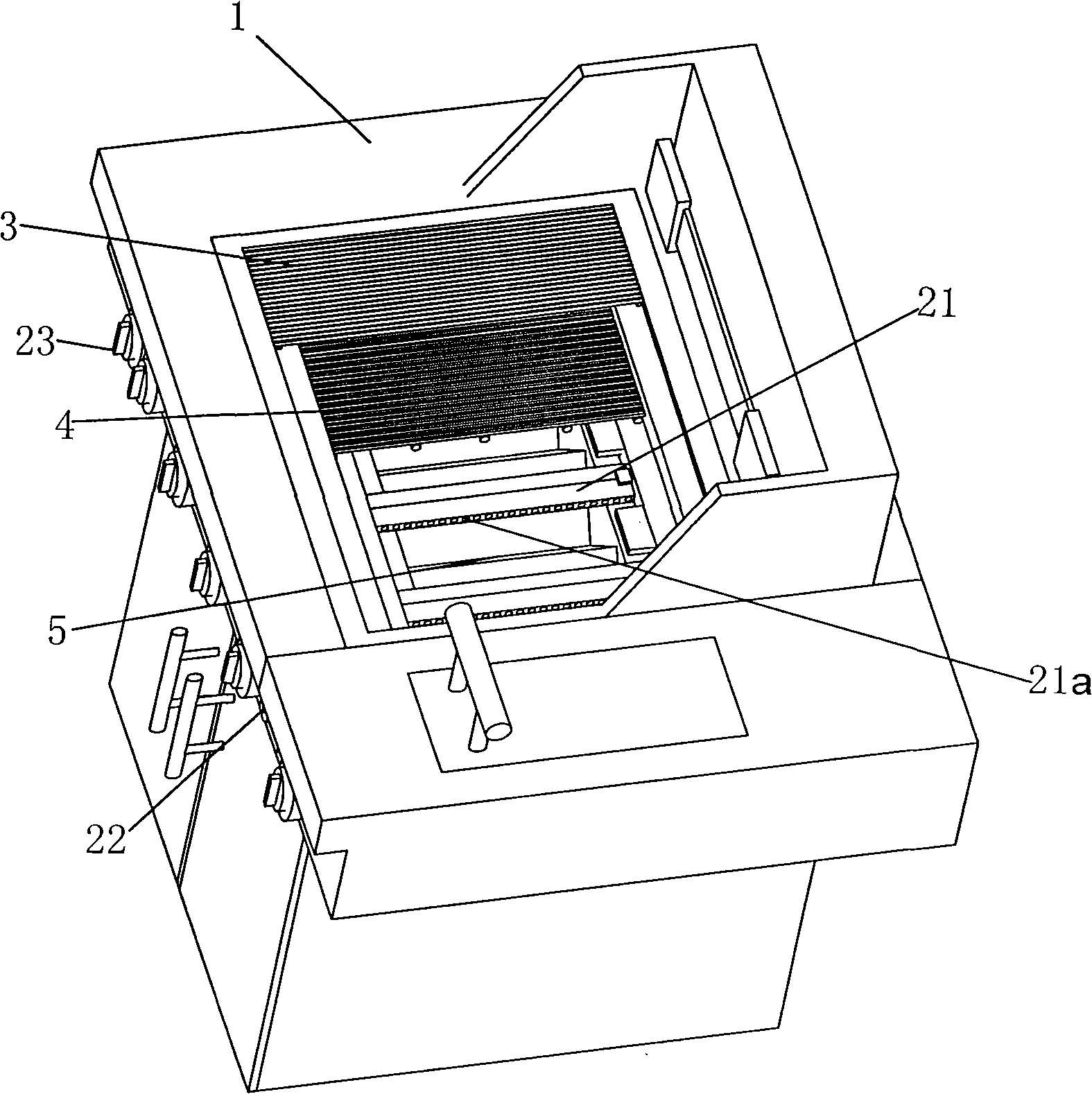

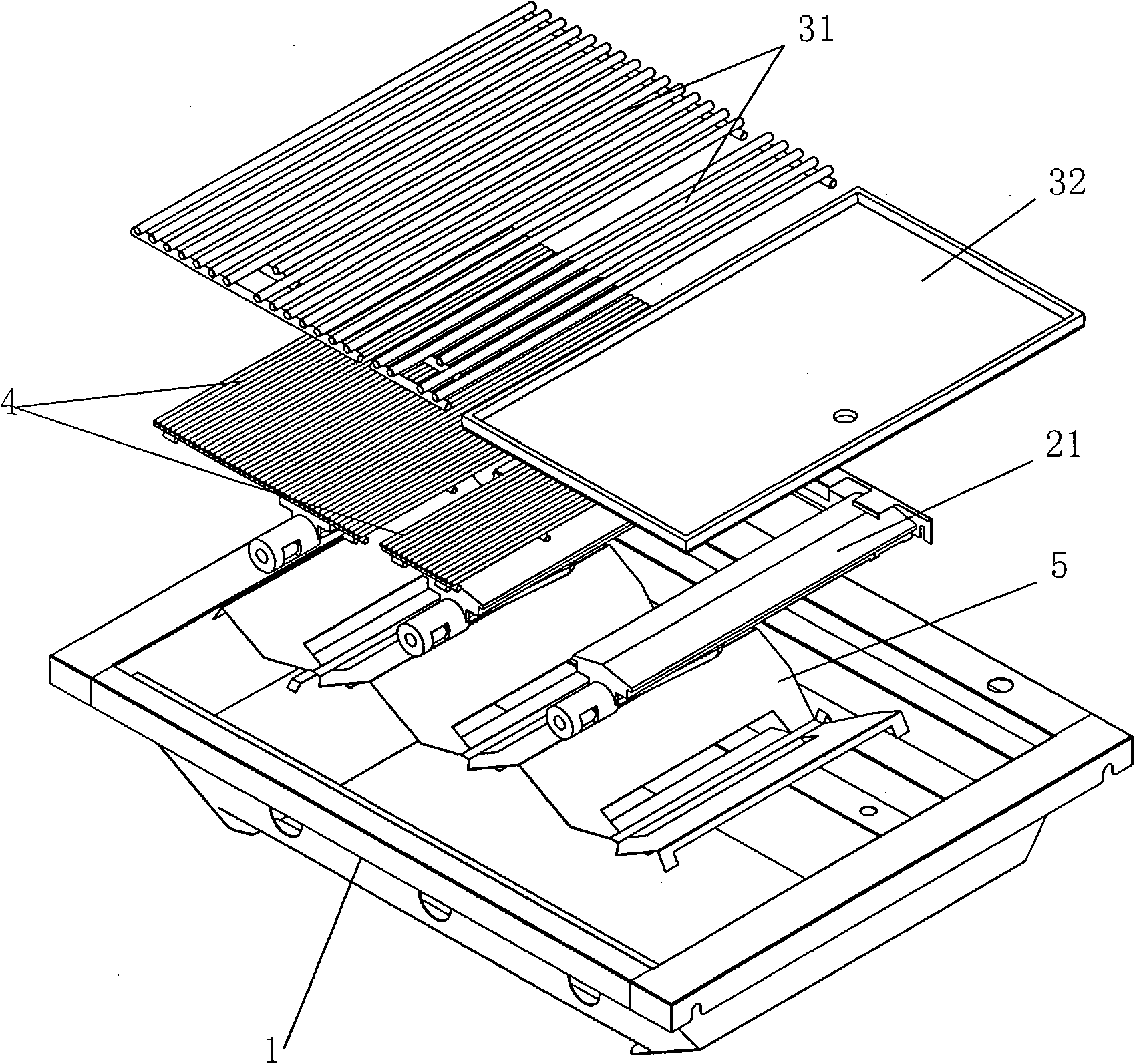

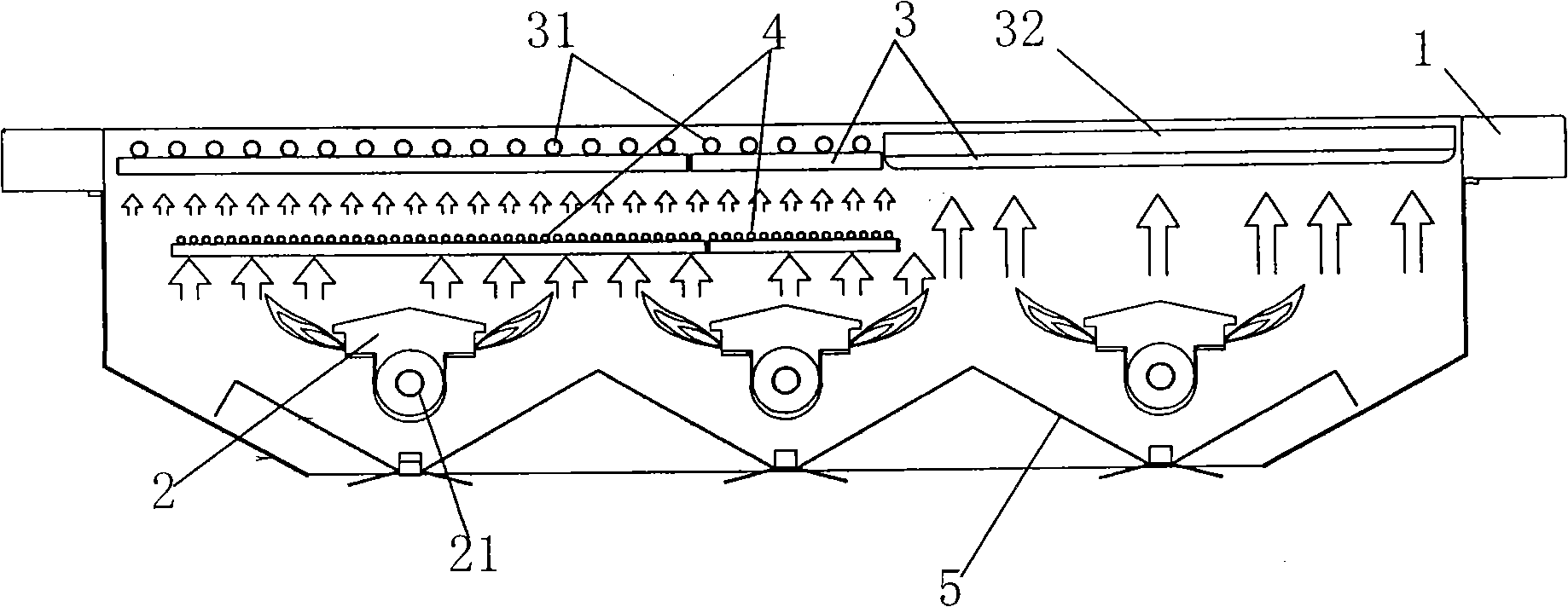

[0018] see figure 1 , figure 2 with image 3 , the present embodiment includes a furnace body 1, a gas burner 2 positioned in the furnace body, and a barbecue layer 3, and the barbecue layer 3 is arranged above the burner head 21 of the gas burner; A net-type thermostat 4, the thermostat 4 is welded by a plurality of stainless steel bars; the burner head 21 is strip-shaped, and a row of horizontally arranged fire holes 21a are respectively arranged on both sides of the burner head 21 .

[0019] In this example:

[0020] The thermostat 4 is welded by circular stainless steel strips, and the strip-shaped through holes formed between the circular stainless steel strips are in the shape of "○○", which can change flames from different directions into vertical upward flames. The intervals of the grids of the thermostat 4 are reasonably set according to the position of the burner 21 , and placed within an appropriate distance above the burner 21 . Since the fire holes 21a of the...

specific Embodiment 2

[0026] The characteristics of this embodiment are: the thermostat 4 is made of stainless steel plate and has a grid-like plane surface formed by a plurality of circular stainless steel strips, and the formed strip-shaped through-holes are in the shape of "○○". Others are the same as in Example 1.

specific Embodiment 3

[0027] The characteristics of this embodiment are: the thermostat 4 is made of a stainless steel plate processed into a plurality of strip-shaped through-holes, and the shape of the formed strip-shaped through-holes can be in the shape of "○○" or oval or other shape. Or the thermostat 4 is formed by processing a metal plate into a plurality of evenly distributed through holes. Others are the same as in Example 1.

[0028] Other examples:

[0029] In other embodiments of the present invention: the furnace body 1, the gas burner 2, the barbecue layer 3, the burner 21 and the grid-type thermostat 4 can be made of stainless steel, alloy steel, stainless iron or other metal materials constitute. One or more furnace heads 21 can be arranged in the furnace body, and correspondingly, a single reflector 5 is provided under each furnace head 21 or a reflector 5 with integrally formed structure is arranged under all the furnace heads 21 . The quantity of the thermostat 4 can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com