Magnetron sputtering target having magnetic field enhancing and adjusting functions

A magnetron sputtering, functional technology, applied in the field of magnetron sputtering targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

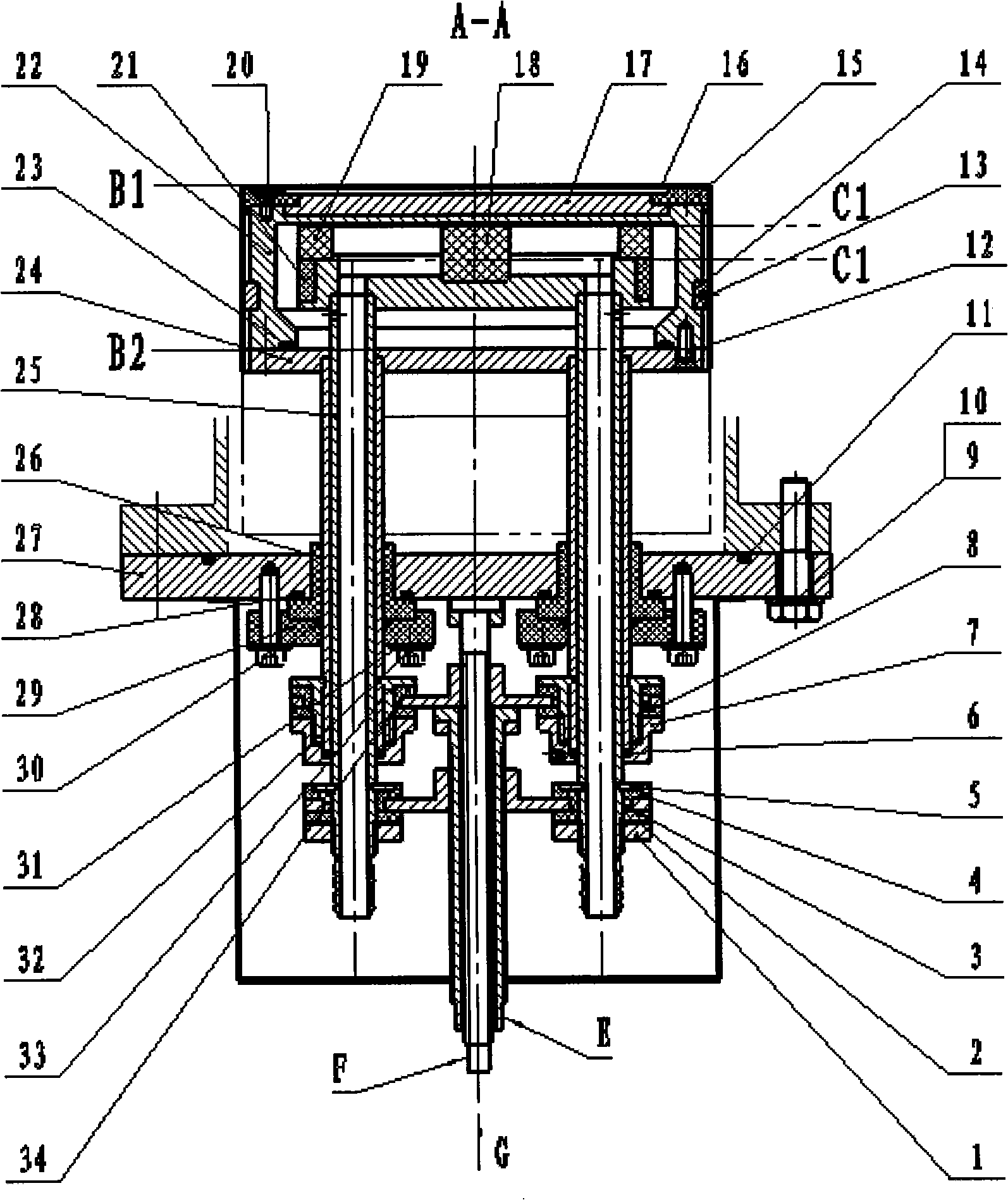

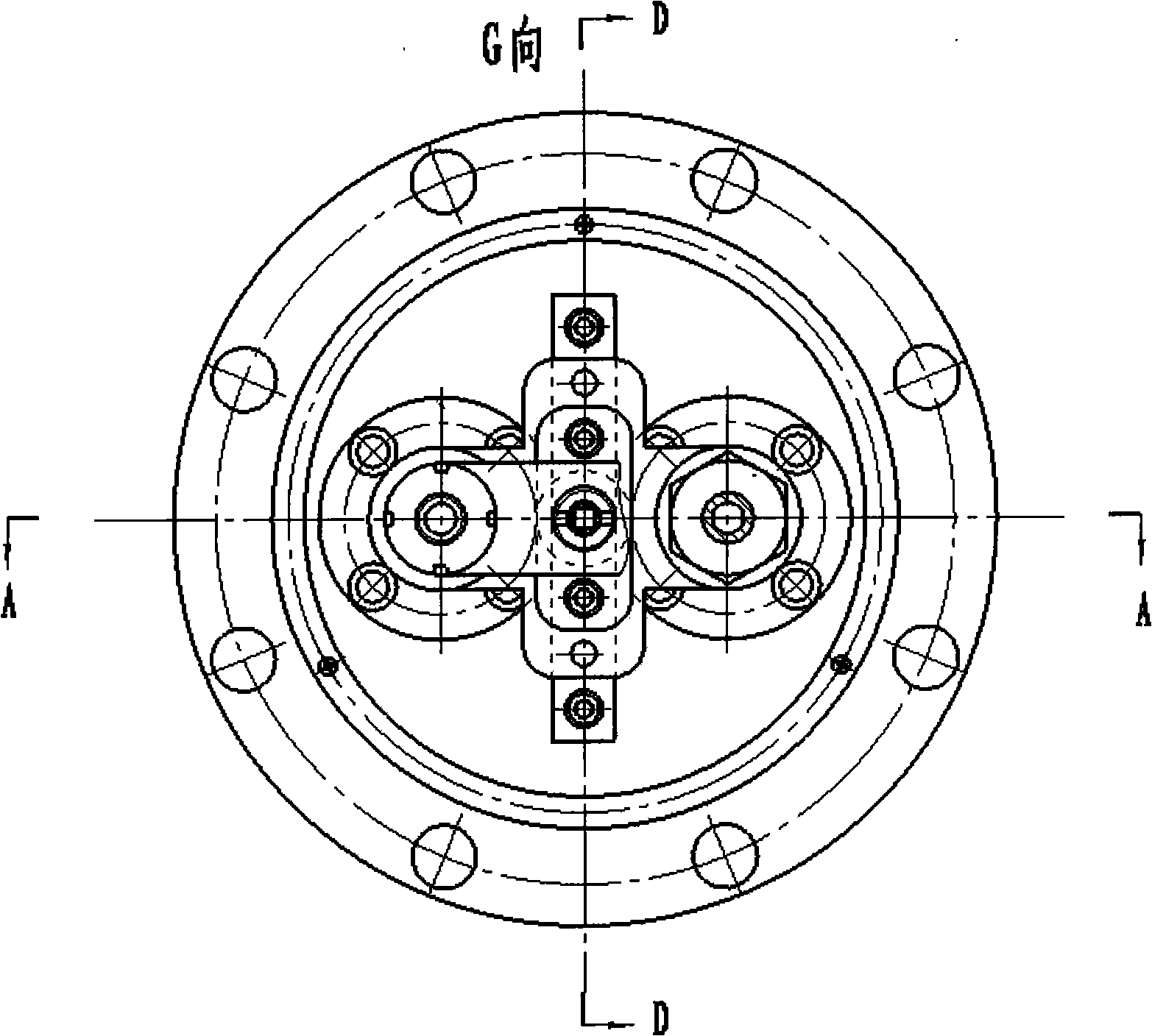

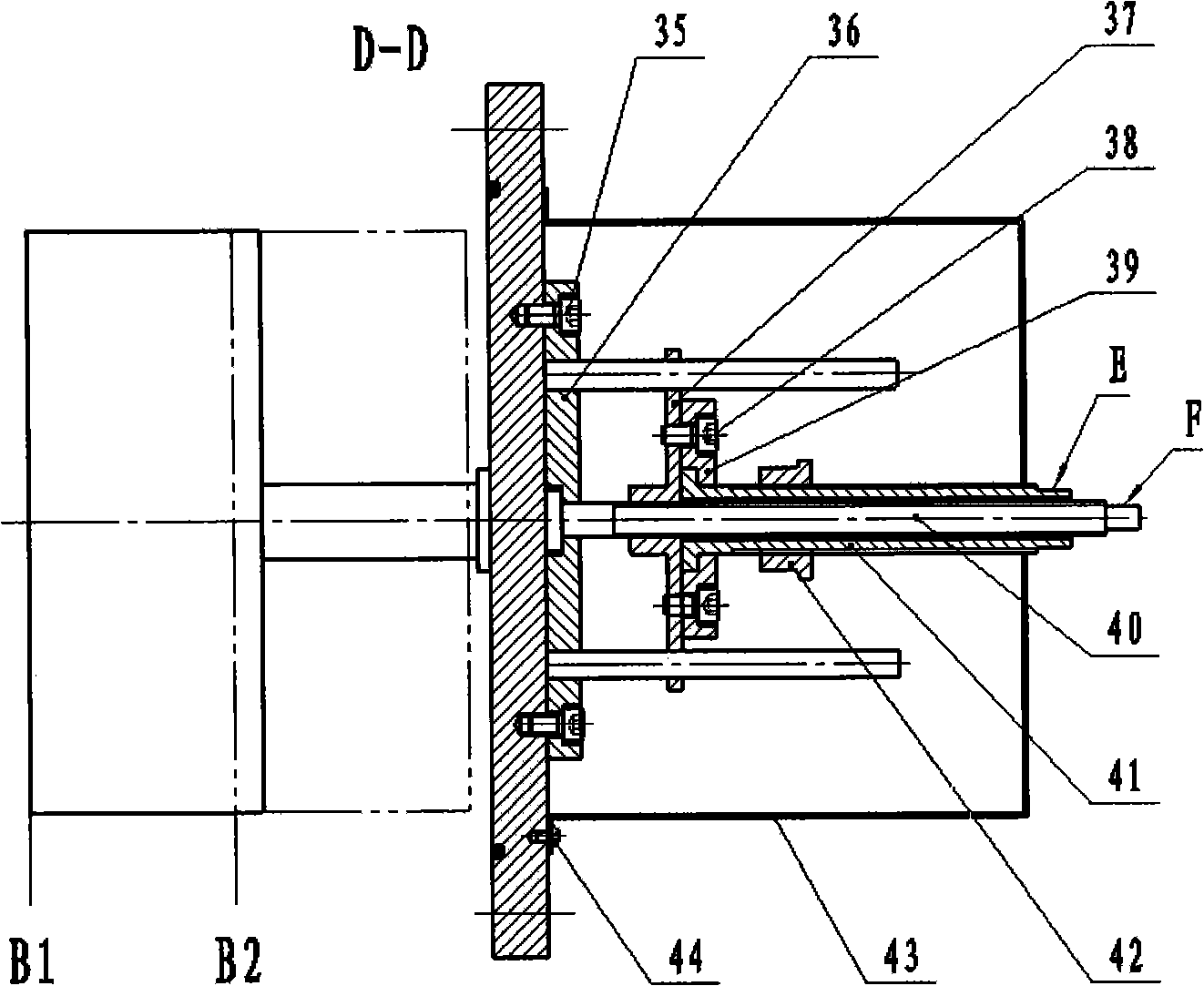

[0018] The composition of this embodiment is as figure 1 As shown: the target shell 22 and the target base 24 constitute the target body, the target material 17 is fixed on the target shell 22 through the pressure ring and the screw IV20, the central magnetic column 18, the positive magnetic ring 19, the side magnetic ring 21 and the magnetic yoke iron 25 form the internal magnetic circuit. Outside the magnetically permeable yoke where the rear part of the positive magnetic ring 19 meets the magnetically permeable yoke 25 , a radially magnetized side magnetic ring 21 is arranged. The axial height of the side magnetic ring 21 is equal to or slightly smaller than the side height of the magnetic yoke iron 25 ; the radial thickness of the side magnetic ring 21 is 1 / 2-1 / 3 of the radial thickness of the positive magnetic ring 19 . The magnetization direction and assembly relationship of the central magnetic column 18, the positive magnetic ring 19 and the side magnetic ring 21 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com