Magnetic anomaly pigging monitoring and blocking positioning method for buried oil and gas transmission pipeline cleaner

A technology for conveying pipelines and positioning methods, which is applied in chemical instruments and methods, cleaning methods and utensils, and the size/direction of magnetic fields, etc., can solve the problem of failure to realize the monitoring of buried pipelines through balls, and failure to solve the problem of pig blocking and positioning. , increase the cost of monitoring equipment and other issues, to avoid affecting the health of employees, to achieve remote monitoring and control, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

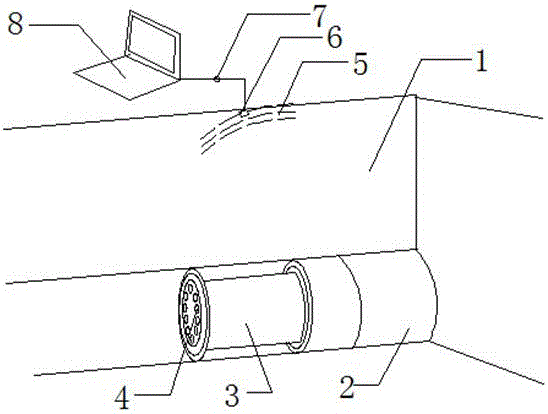

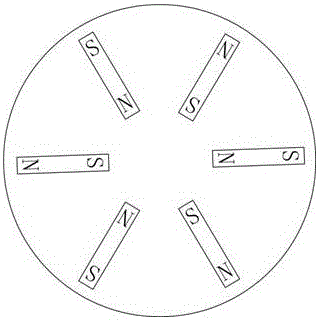

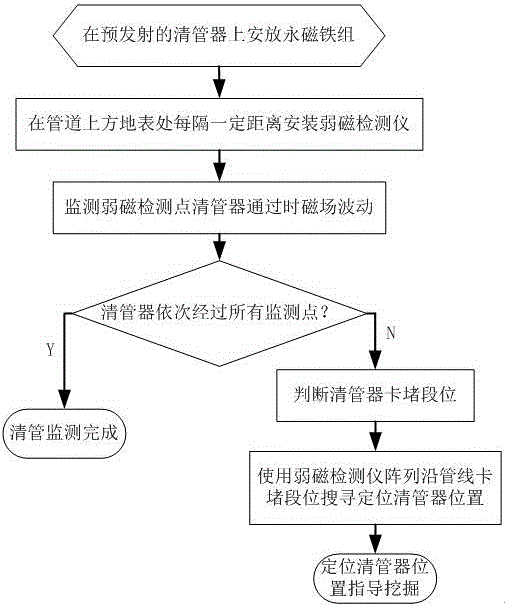

[0033] Such as figure 1 As shown, a buried pipeline 2 is provided under the soil 1, and a pig 3 is arranged in the buried pipeline 2. During the working process of the pig 3, six cylindrical aluminum-iron-boron pipes with a length of 12 cm and a diameter of 5 cm Strong magnetic permanent magnet (the surface magnetic induction is greater than 1.5T), such as figure 2 As shown, the magnetic source 4 of the radial permanent magnet group is fixed and arranged radially in the metal aluminum disc. The magnetic source is installed at the tail end of the pig 3 and advances with the pig; the weak magnetic detector 6 uses a single-axis fluxgate The sensor is used as a magnetic field detection probe, and the magnetic field weakening detector 6 is fixed in a plastic sleeve and buried in the surface soil 1. The magnetic field sensitive direction of the sensor is parallel to the direction of the magnetic force line when the magnetic field is the largest when the pig 3 passes through; the di...

Embodiment 2

[0038]A buried oil and gas transmission pipeline pig magnetic abnormal ball monitoring and jamming positioning method, the magnetic field weakening detector array is: after the pig is jammed, the single-axis magnetic flux used for ball ball detection is collected The gate weak magnetic detector is installed on the magnetic anomaly detection bracket to form a detection array, which is used for the detection of magnetic anomalies above the pig.

[0039] In this embodiment, the single-axis fluxgate magnetic field weakening detector directly collected and used for passing ball detection is installed on the magnetic anomaly detection bracket to form a detection array, so that the single-axis fluxgate magnetic field weakening detector can be reused, reducing the cost of the instrument. Preparation costs.

[0040] The invention installs a disk magnetic source composed of permanent magnet radial arrangement at the rear end of the pig, and uses a single-axis fluxgate weak magnetic dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com