Method and rock drilling rig for hole drilling

A technology for rock drilling and equipment, which is used in the field of drilling and rock drilling equipment, and can solve the problems of heavy base and large static force of rotary drilling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

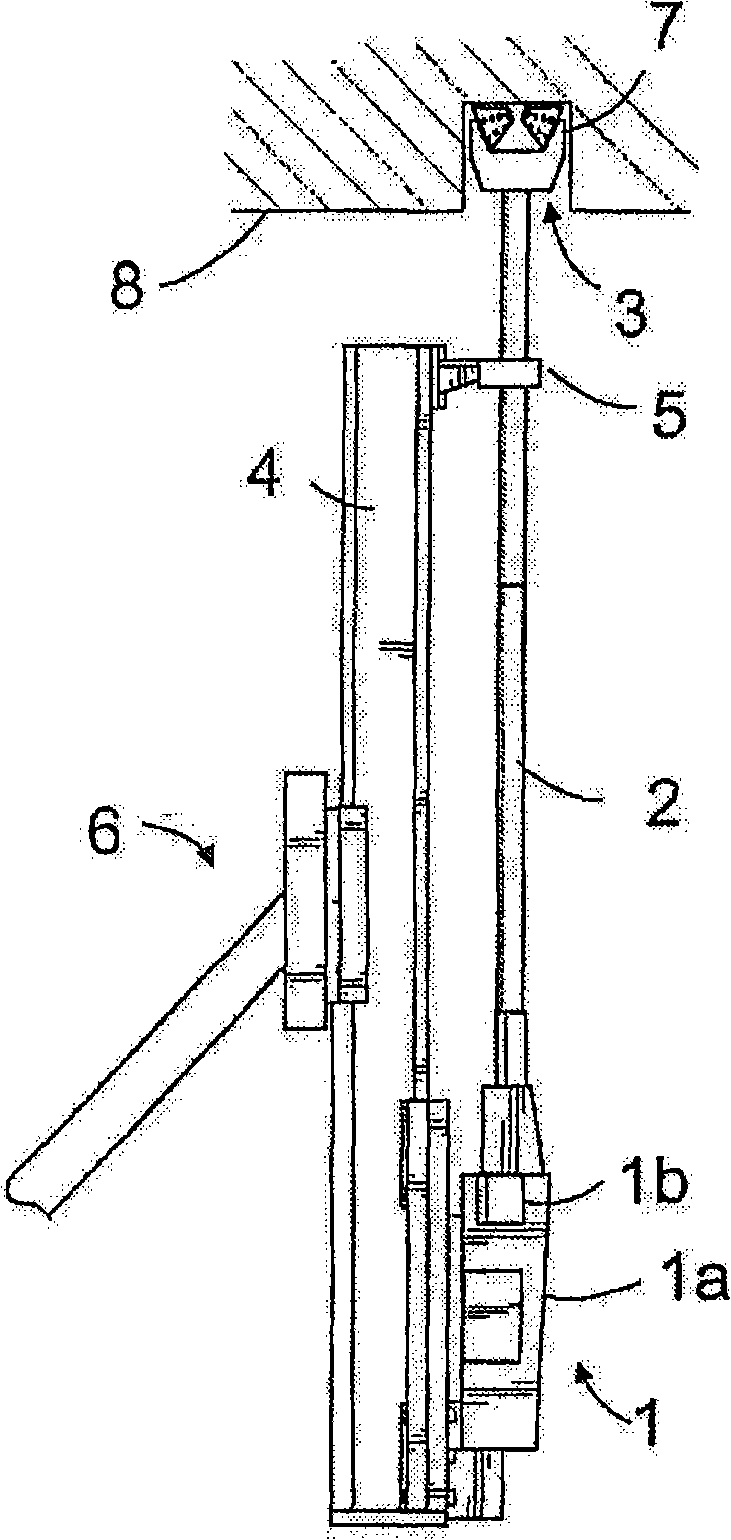

[0014] The figures show a tophammer rock drilling apparatus comprising a rock drilling machine 1 , a drill rod 2 connected to the rock drilling machine and a conical roller cone bit 3 connected at the end of the drill rod. The rock drilling machine 1 includes a percussion device 1a and a rotary motor 1b. The impact device 1a transmits impact to the cone bit 3 via the drill rod 2, and accordingly, the rotary motor 1b rotates the drill rod and the cone bit 3 together therewith. Their structure and operation are known per se, so a more detailed description of them is not required.

[0015] Generally, the percussion device is moved along the feed beam 4 in a manner known per se and by means of a feed mechanism known per se, at the end of which there is usually a drilling guide 5, which Serves to guide the drill rod and thus the drill bit during drilling. The feed beam 4 is in turn usually connected to the base of the rock drilling rig (not shown) together with a boom 6 or the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com