Treatment system and technology for fermented antibiotics wastewater

A technology of antibiotic wastewater and treatment process, which is applied in the direction of biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of complex treatment process, high content of suspended solids, and imbalance of carbon and nitrogen nutrition ratio, and achieve Improve the removal efficiency, simplify the treatment process, and increase the effect of volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

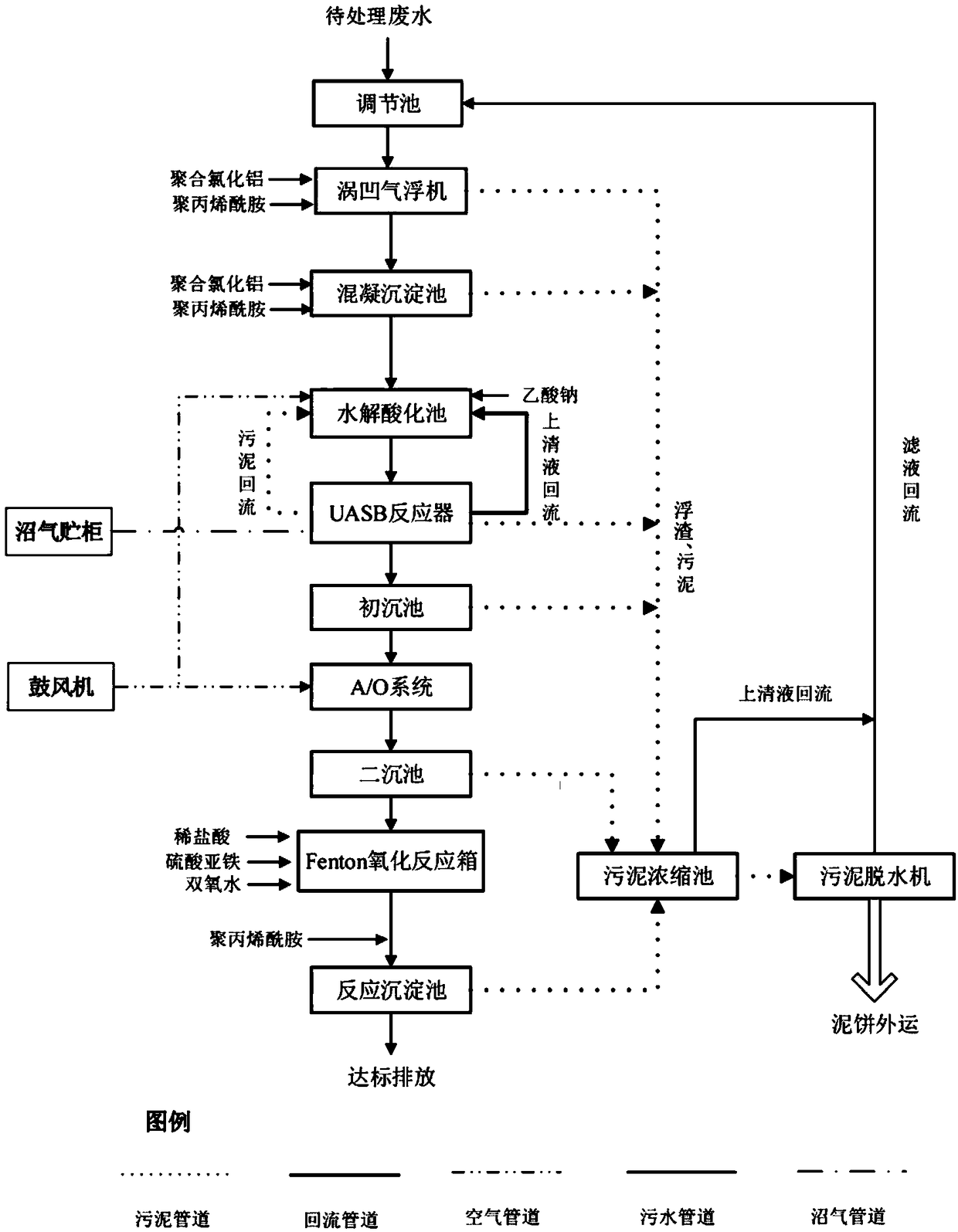

[0041] A treatment system for fermented antibiotic wastewater, such as figure 1 As shown, including regulating tank, vortex concave air flotation machine, coagulation sedimentation tank, hydrolysis acidification tank, UASB reactor, primary sedimentation tank, A / O system, secondary sedimentation tank, Fenton oxidation reaction box, reaction sedimentation tank, sludge concentration pool.

[0042] A submersible mixer is installed in the adjustment tank to achieve the purpose of balancing water quality and quantity, prevent the accumulation of sediment at the bottom of the adjustment tank, and ensure the stable operation of the subsequent treatment section. The coagulation sedimentation tank has a mixing area and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com