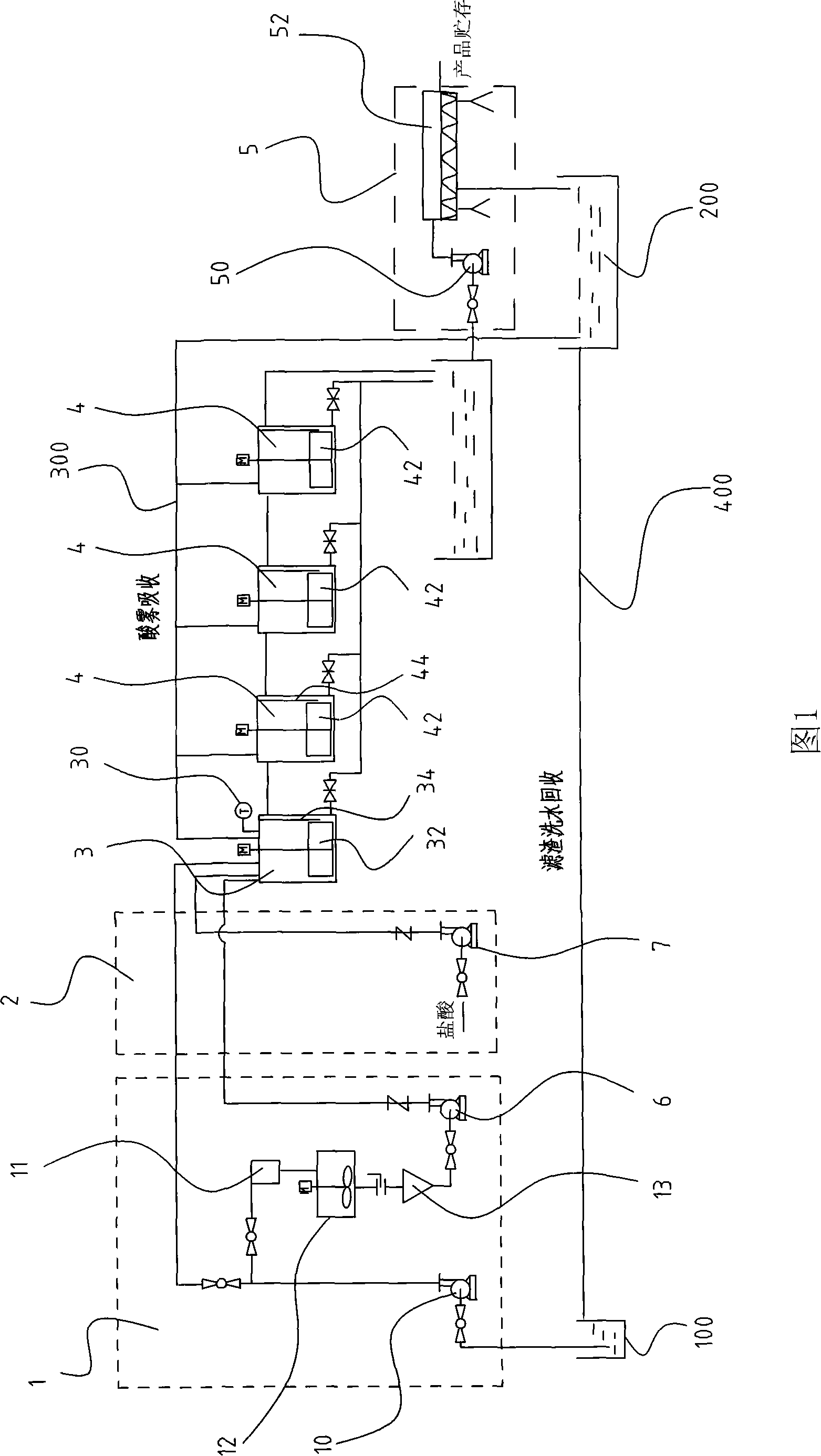

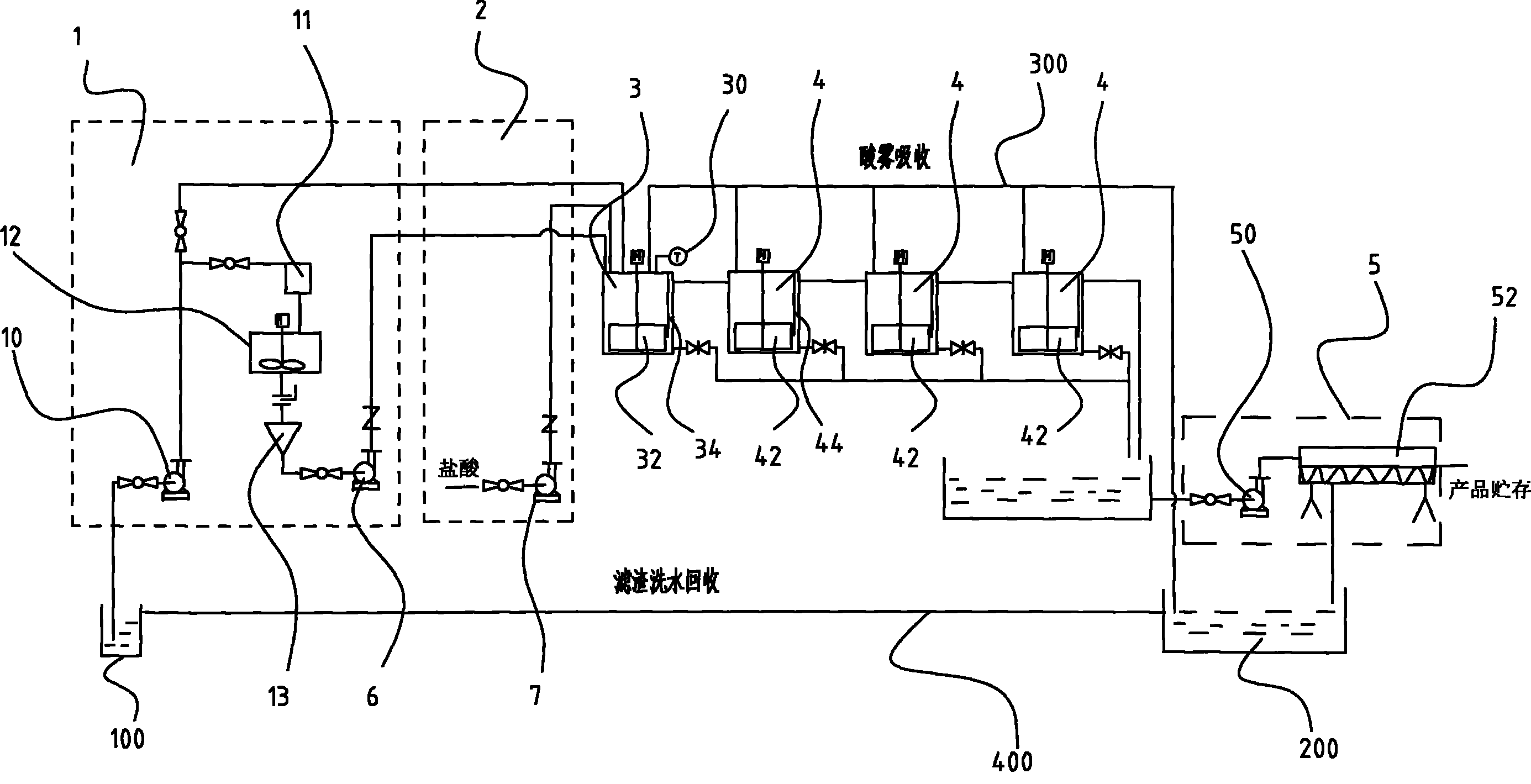

Continuous production process for polyaluminium chloride and production equipment

A technology of polyaluminum chloride and production equipment, which is applied in the directions of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc. High operational safety, low energy and material losses, improved mixing reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the concentration of industrial concentrated hydrochloric acid, a certain amount of water (or waste acid) is added in proportion to the hydrochloric acid pool and mixed so that the concentration of HCl% in the hydrochloric acid is 14%, and it is used after stirring evenly.

[0033] Put calcium aluminate powder and water into the slurry mixer at a ratio of 7:3 (mass ratio) each time, stir until the slurry becomes paste, open the discharge door and put the slurry into the slurry funnel. After the slurry in the slurry mixer is completely put into the slurry funnel, add calcium aluminate powder and water in proportion in time to ensure that there is enough slurry in the slurry funnel to be continuously pumped into the reaction kettle.

[0034] Use the hydrochloric acid metering pump to pump hydrochloric acid at 800L / h and the slurry metering pump to pump the slurry at a speed of 148L / h into the reaction kettle at the same time, control the stirring speed at 63rp...

Embodiment 2

[0036]According to the concentration of industrial concentrated hydrochloric acid, a certain amount of water (or waste acid) is added in proportion to the hydrochloric acid pool and mixed so that the concentration of HCl% in the hydrochloric acid is 16%, and it is used after stirring evenly.

[0037] Put calcium aluminate powder and water into the slurry mixer at a ratio of 7:3 (mass ratio) each time, stir until the slurry becomes paste, open the discharge door and put the slurry into the slurry funnel. After the slurry in the slurry mixer is completely put into the slurry funnel, add calcium aluminate powder and water in proportion in time to ensure that there is enough slurry in the slurry funnel to be continuously pumped into the reaction kettle.

[0038] Use the hydrochloric acid metering pump to pump hydrochloric acid at 1000L / h and the slurry metering pump to pump the slurry at a speed of 195L / h into the reaction kettle at the same time, control the stirring speed at 63rp...

Embodiment 3

[0040] According to the concentration of industrial concentrated hydrochloric acid, a certain amount of water (or waste acid) is added in proportion to the hydrochloric acid pool and mixed so that the concentration of HCl% in the hydrochloric acid is 16%, and it is used after stirring evenly.

[0041] Put calcium aluminate powder and water into the slurry mixer at a ratio of 7:3 (mass ratio) each time, stir until the slurry becomes paste, open the discharge door and put the slurry into the slurry funnel. After the slurry in the slurry mixer is completely put into the slurry funnel, add calcium aluminate powder and water in proportion in time to ensure that there is enough slurry in the slurry funnel to be continuously pumped into the reaction kettle.

[0042] Use a hydrochloric acid metering pump to pump hydrochloric acid at 600L / h and a slurry metering pump to pump the slurry at a speed of 120L / h into the reaction kettle at the same time, control the stirring speed at 63rpm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com