Method and device for preparing superfine amorphousn cefuroxime axetil

A cefuroxime axetil and amorphous technology, which is applied in the field of preparation of ultrafine amorphous cefuroxime axetil, can solve the problems of high solvent cost, small particle size, and narrow particle size distribution, and achieve high reaction efficiency and narrow particle size distribution , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of superfine amorphous cefuroxime axetil of the present invention, it comprises the following steps:

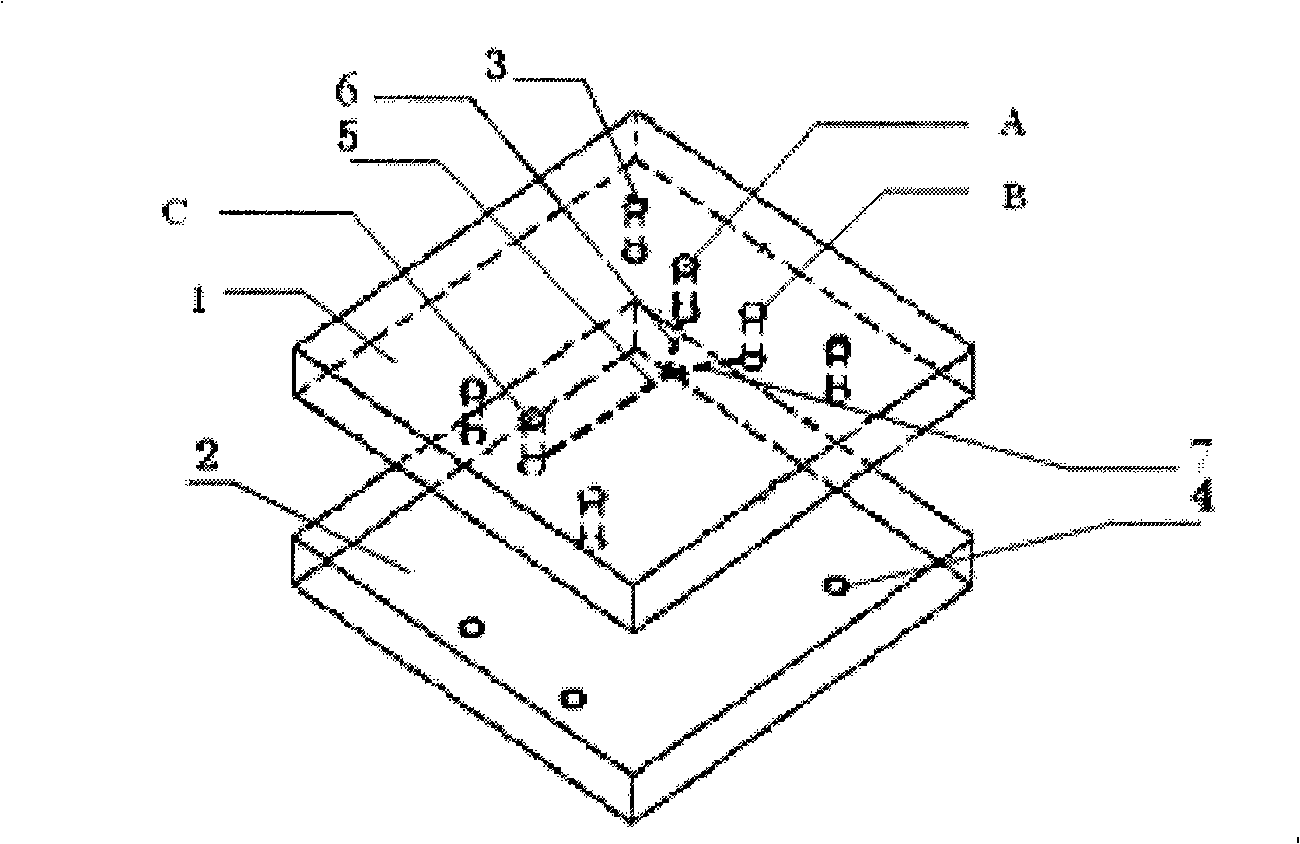

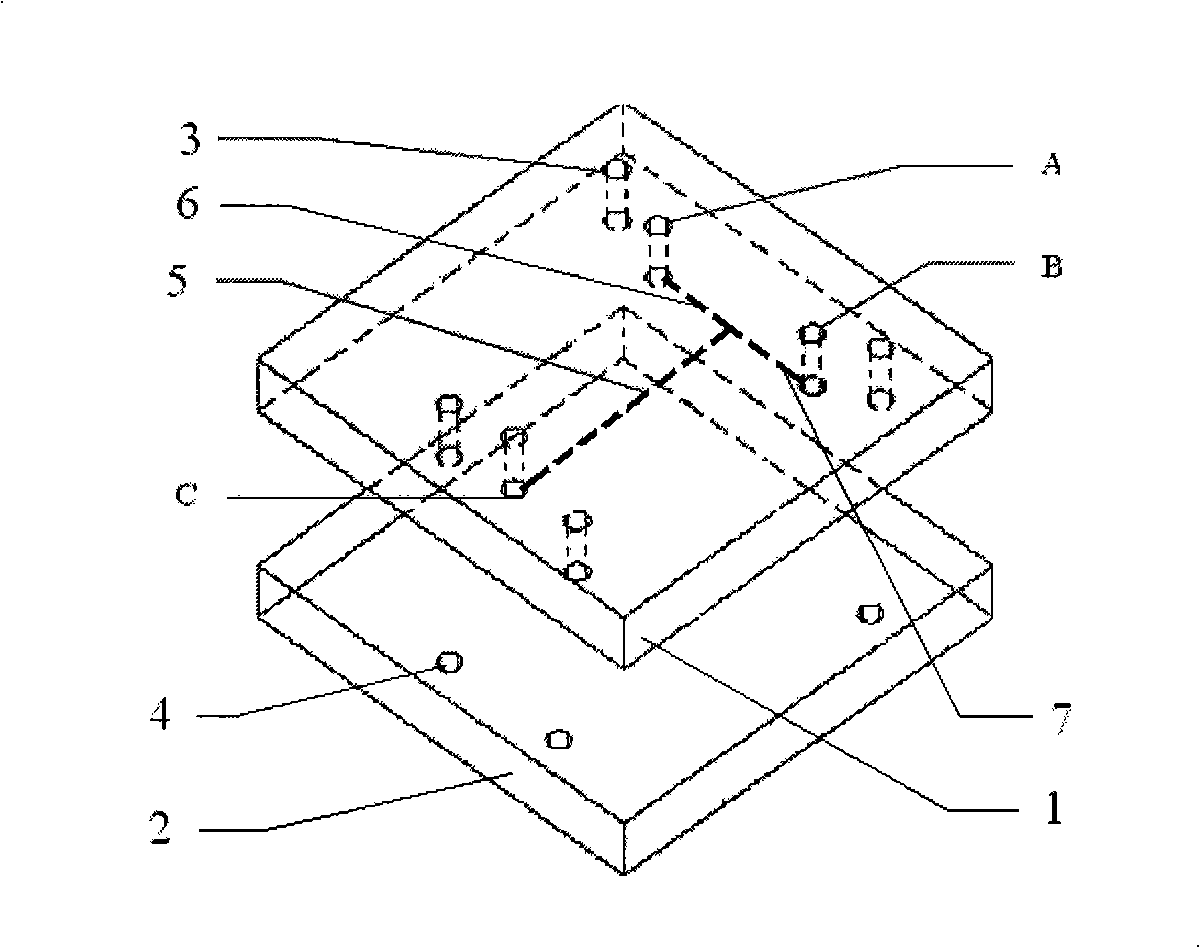

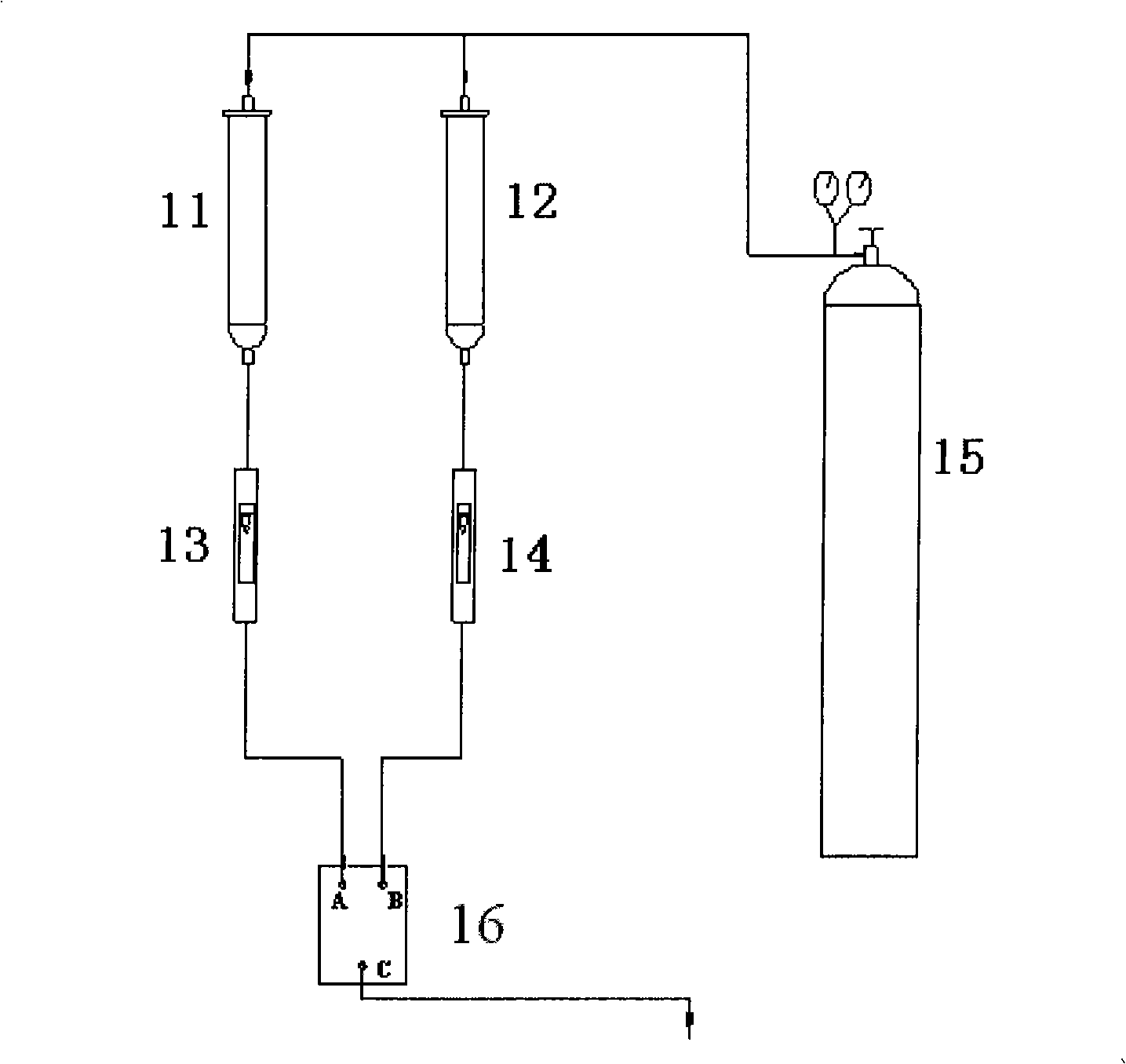

[0030] Dissolve crystalline cefuroxime axetil in an acetone solvent, wherein the concentration of the solution containing cefuroxime axetil is 1% (w / v) to 20% (w / v) to obtain a cefuroxime axetil solution, and place in storage Tank 11; measure deionized water and place it in storage tank 12, the type of storage tank 12 and storage tank 11 can be the same, the volume ratio of cefuroxime axetil solution to deionized water is: 1:5~1:50, at the reaction temperature At -25°C to 70°C, unscrew the nitrogen valve of the nitrogen tank 15 to adjust the pressure to 0.2MPa, and the two liquids in the storage tank 11 and the storage tank 12 pass through the rotameters 13 and 14 respectively through the solvent feed port A and the The anti-solvent feed port B enters the microreactor 16, and after rapid contact and efficient mixing, a white cefuroxime axet...

Embodiment 1

[0038] Take by weighing crystalline cefuroxime axetil 100g, be dissolved in acetone, obtain cefuroxime axetil solution 100ml, place storage tank 11, measure deionized water 1000ml and place storage tank 12, cefuroxime axetil solution and deionized water The volume ratio is 1:10. At room temperature, two streams of liquid enter from the feed port A and B of the "Y" microreactor respectively. Mix to generate white cefuroxime axetil precipitate, which is discharged from outlet C, filtered, washed, and dried to obtain ultrafine amorphous cefuroxime axetil particles.

[0039] Figure 4 It is the XRD spectrum of crystalline cefuroxime axetil.

[0040] Figure 5 It is the XRD spectrum of the amorphous cefuroxime axetil obtained according to Example 1 of the present invention.

Embodiment 2

[0042] Take by weighing crystalline cefuroxime axetil 100g, be dissolved in acetone, obtain cefuroxime axetil solution 100ml, place storage tank 11, measure deionized water 2000ml and place storage tank 12, cefuroxime axetil solution and deionized water The volume ratio is 1:20. At room temperature, the two streams of liquid enter from the inlets A and B of the "T" microreactor respectively. Mix to generate white cefuroxime axetil precipitate, which is discharged from outlet C, filtered, washed, and dried to obtain ultrafine amorphous cefuroxime axetil particles. From Figure 6 It can be seen from the scanning electron microscope photos that the average particle size is about 400nm, and at least 80% of the particles have a particle size of 300-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com