Remote control submarine pipeline coupler

A submarine pipeline and remote control technology, applied in the direction of couplings, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems such as use restrictions, achieve improved stress conditions, easy disassembly and replacement, and clear mechanism movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

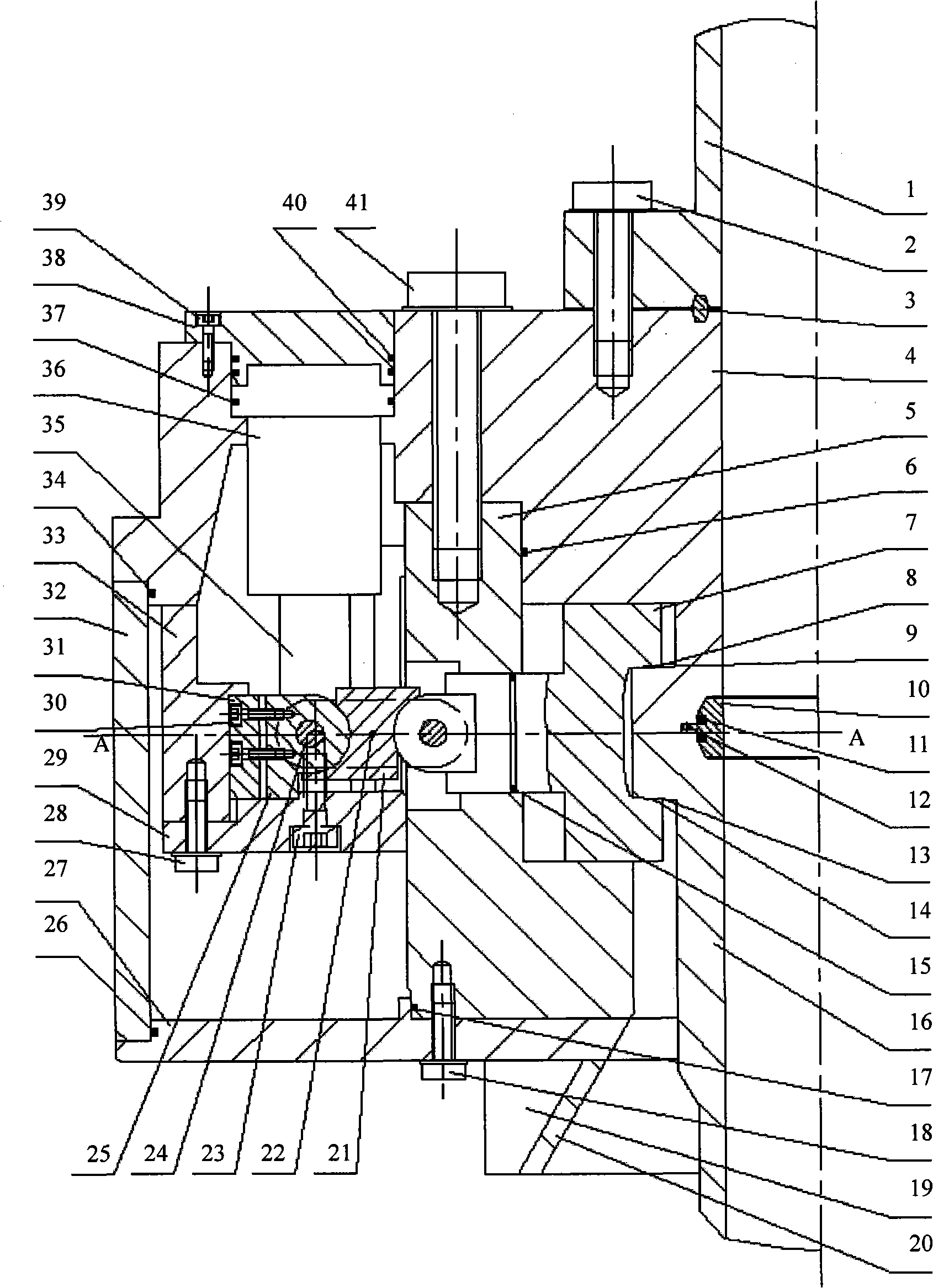

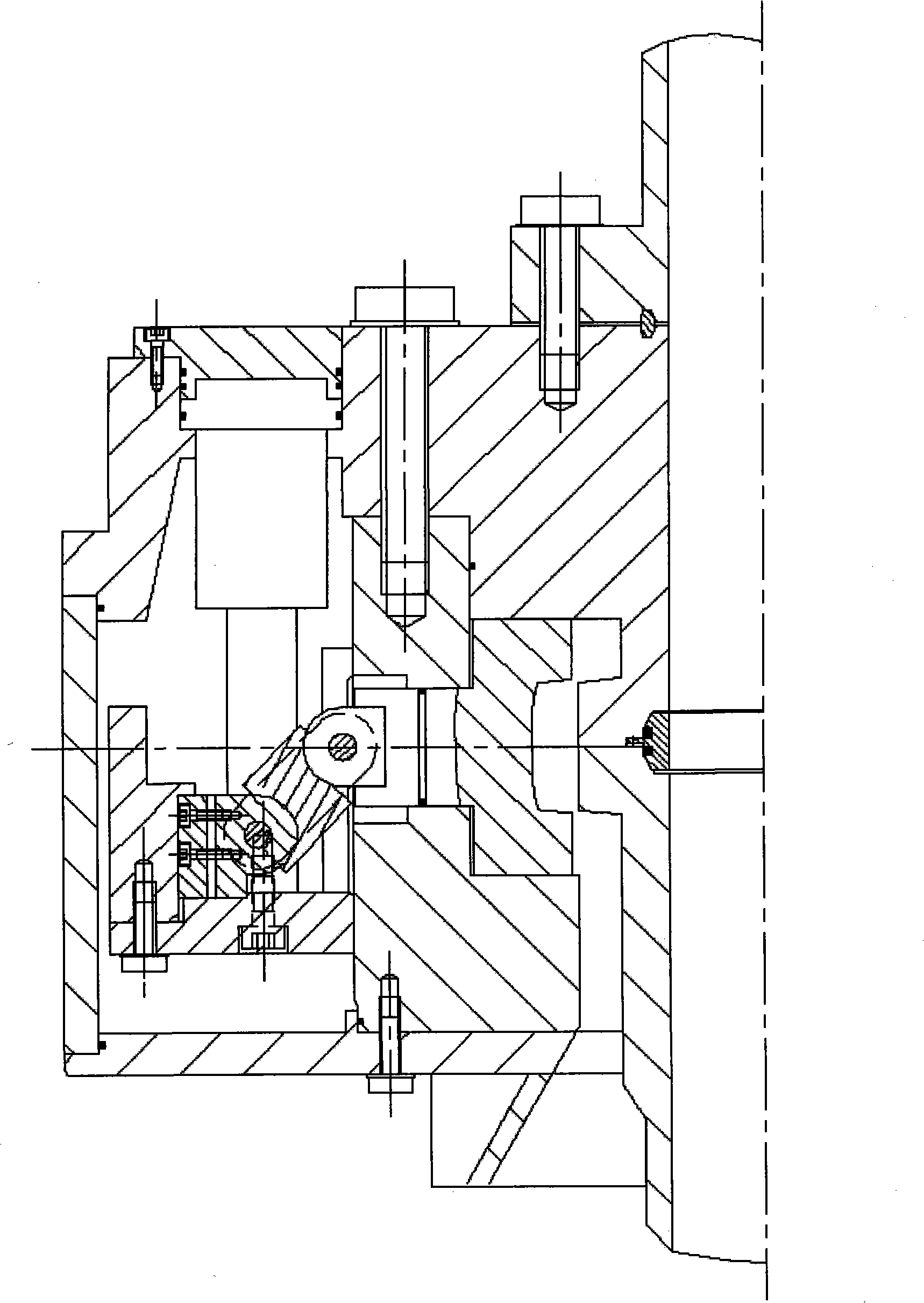

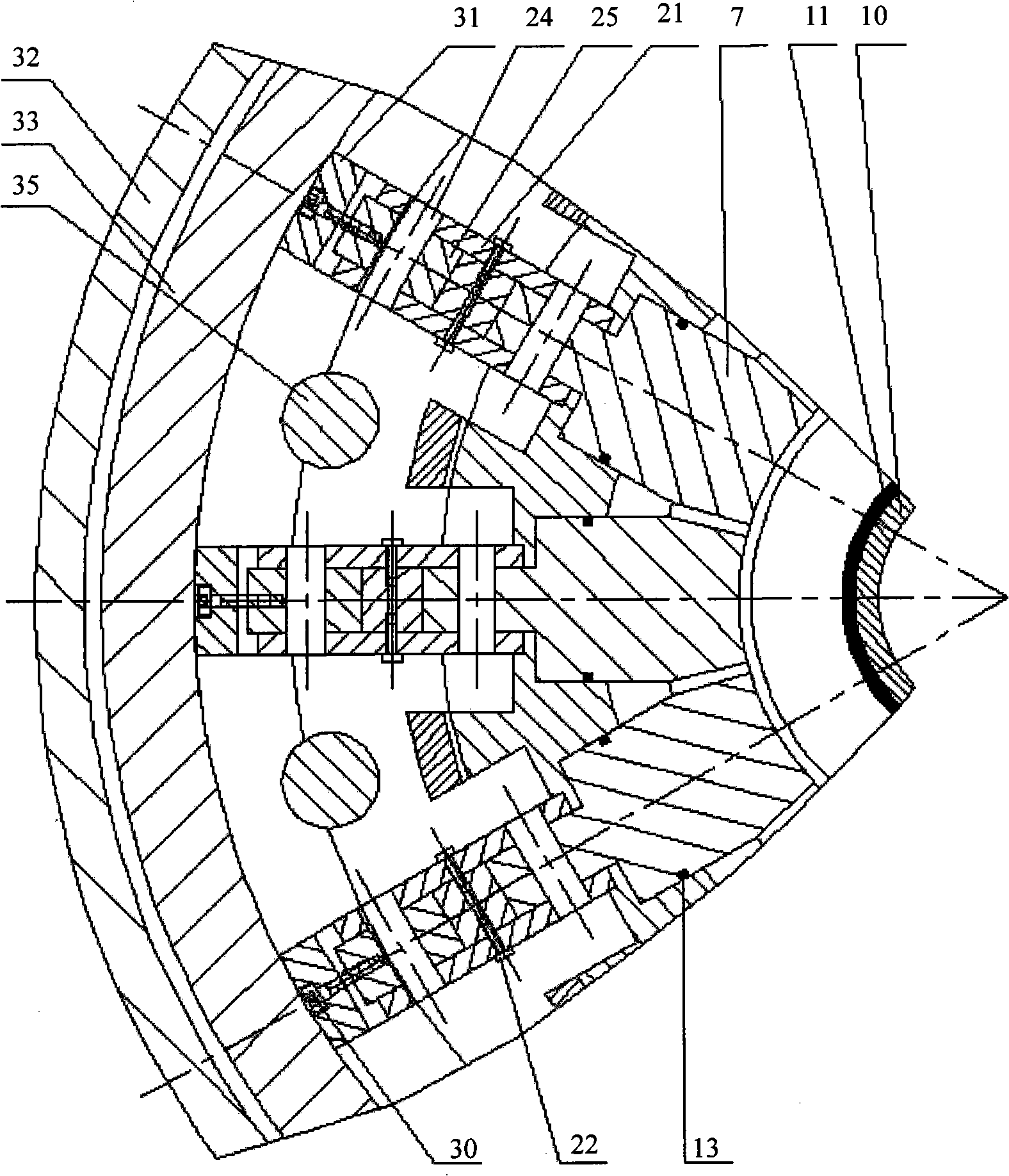

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0025] combine Figure 1 to Figure 4 , the main components include: pipe to be connected 1, bolt 2, metal octagonal or oval pad 3, pipe joint 4, support 5, O-ring 6, sliding claw 7, pipe joint matching taper 8, The upper part of the claw fits the taper hole 9, the lens pad body 10, the O-ring 11, the screw 12, the submarine pipe fits the taper surface 13, the lower part of the claw fits the taper hole 14, the O-ring 15, the submarine pipe 16, the O-ring 17, Bolt 18, guide cone 19, reinforcing rib 20, connecting rod 21, bolt 22, screw 23, pin shaft 24, bearing journal 25, O-ring 26, bottom plate 27, bolt 28, sliding ring plate 29, screw 30 , connecting block 31, barrel member 32, positioning ring 33, O-ring 34, double-acting piston 35, hydraulic cylinder 36, O-ring 37, gland 38, screw 39, O-ring 40, bolt 41, ring Shaft 42, ring hole 43, adapter 44, screw 45, pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com