Ring shell and tube type heat exchanger possessing commutation function

A heat exchanger and annular tube technology, which is applied in the field of heat exchange devices and annular shell-and-tube heat exchangers, can solve the problems of destroying the performance of the temperature field, and the constant temperature tank cannot be used continuously, so as to improve the performance of the temperature field and facilitate the internal uniformity. The effect of heat exchange and promotion of horizontal stirring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

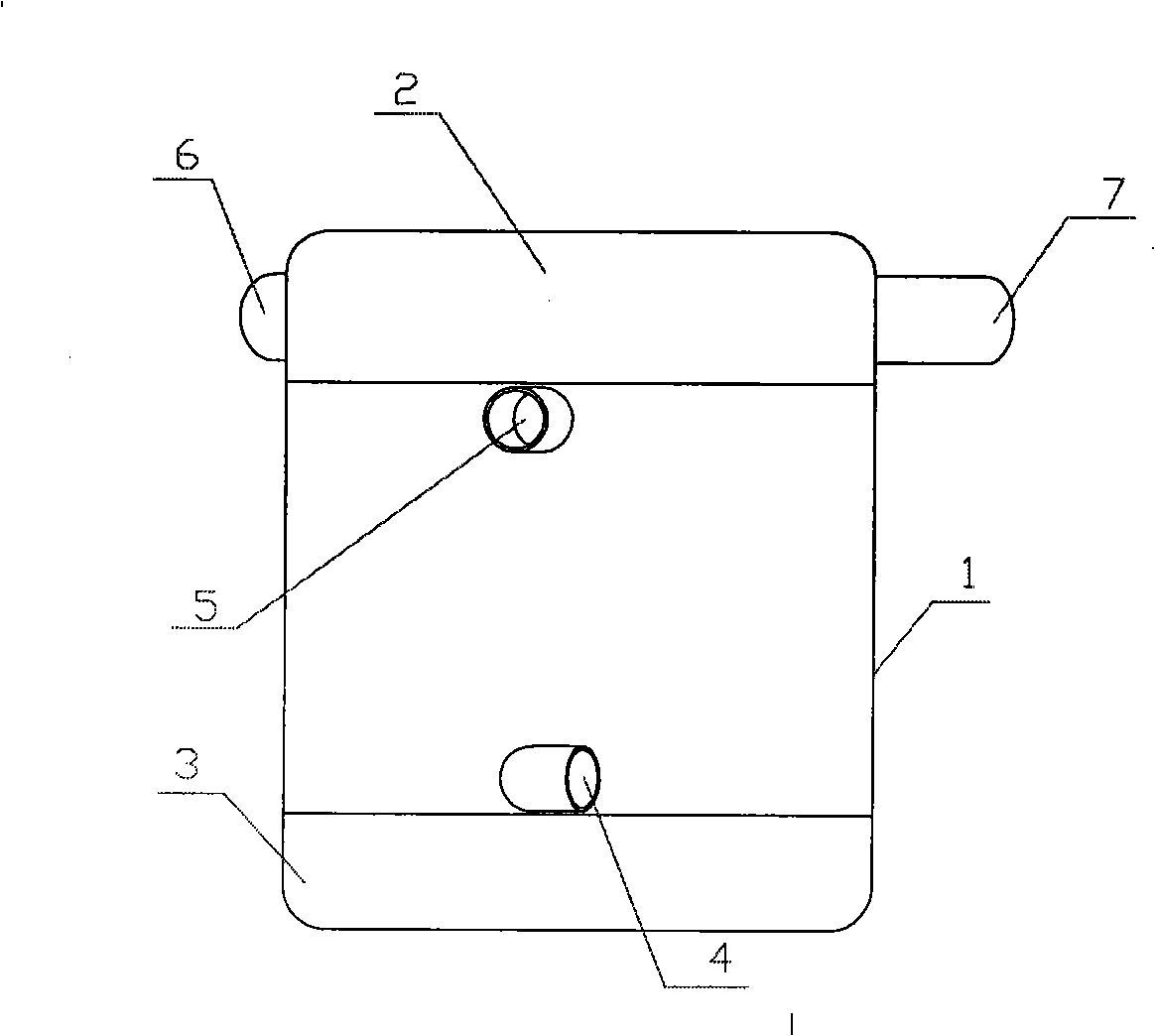

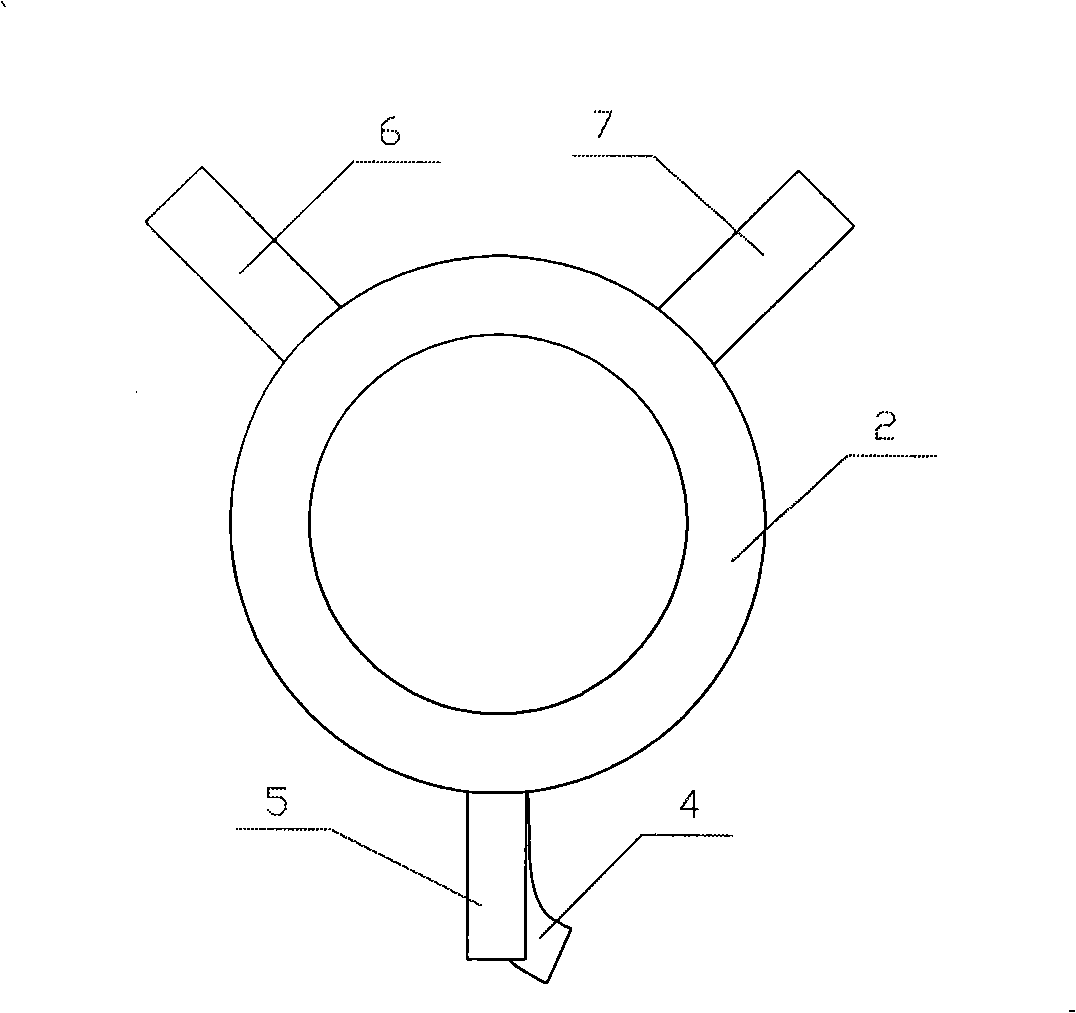

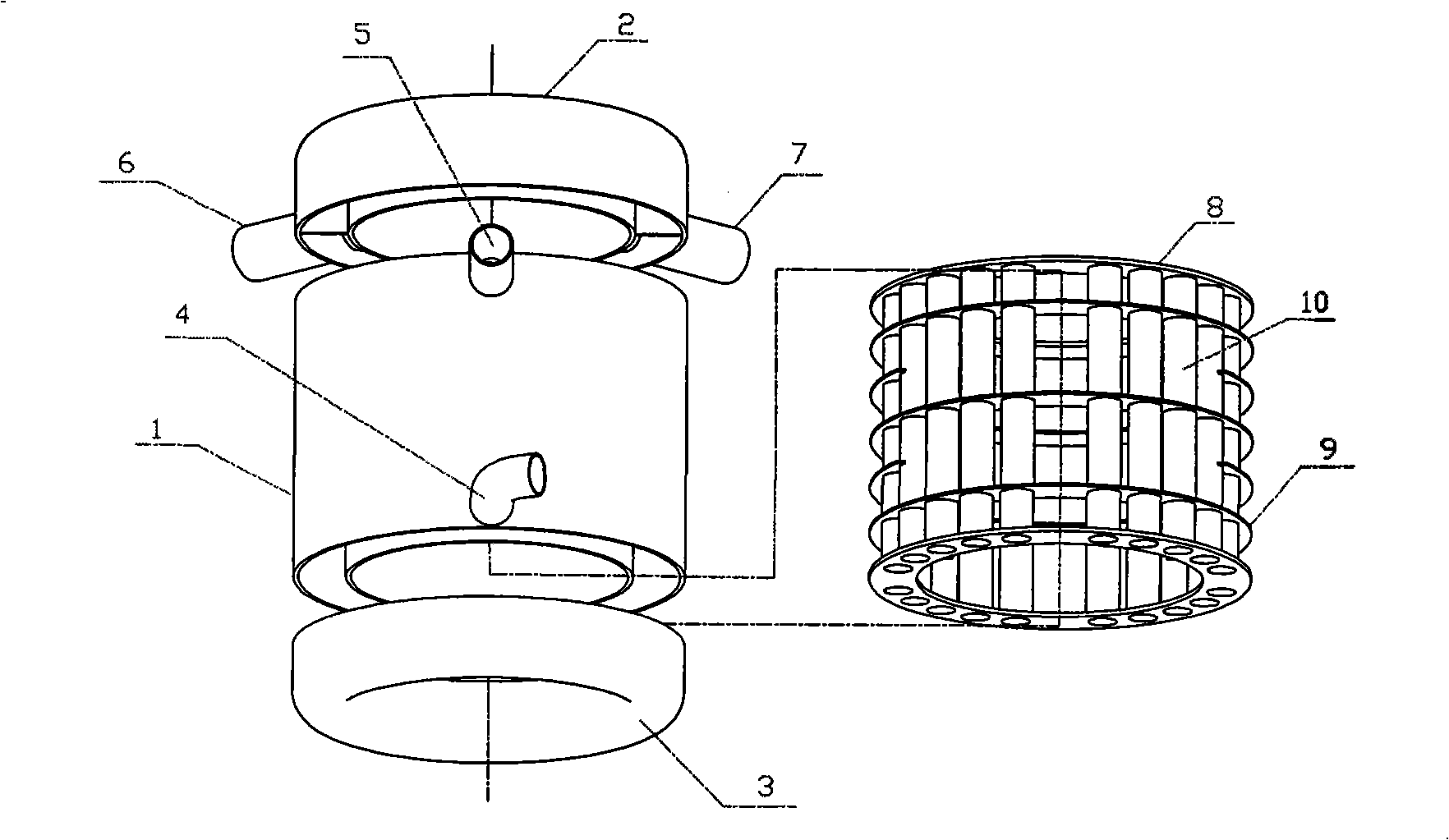

[0030] Please refer to Figure 1 to Image 6 , the present invention is a ring-shaped shell-and-tube heat exchanger with a rectification function, which is a ring-shaped vertical structure as a whole, and the interior is hollow. 1. Constant temperature liquid input pipeline 4, constant temperature liquid output pipeline 5, heat exchange medium input pipeline 6, heat exchange medium output pipeline 7 and core body. The housing 1 is a hollow barrel-shaped interlayer structure. The outer lower part of the housing 1 has a constant temperature liquid input pipe 4 that gradually transitions from a straight line to a circular arc and extends horizontally. Constant temperature liquid output pipeline 5. The upper cover body 2 is an annular groove-shaped structure matched with the shell, with a separator 11 for controlling the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com