Multi-grating programmable full color spectrometer and monitoring method facing to foodstuff safety monitoring

A food safety and spectrometer technology, applied in the field of instrument analysis, can solve the problems of complex MEMS process, difficult quality assurance, weak food safety monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

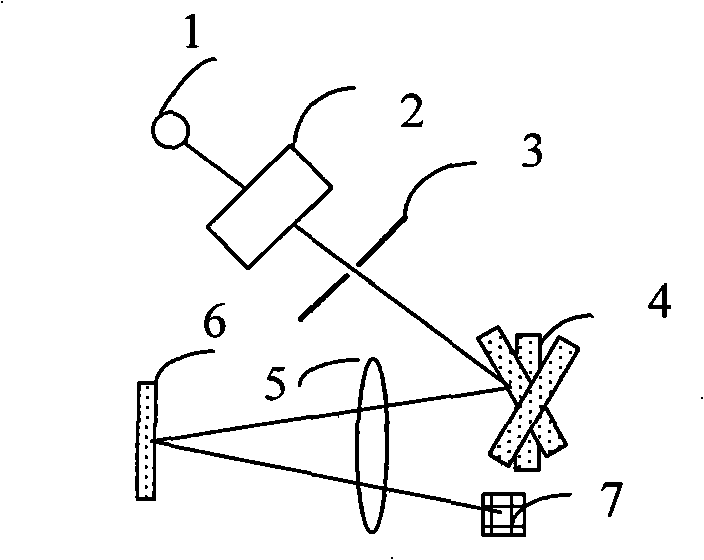

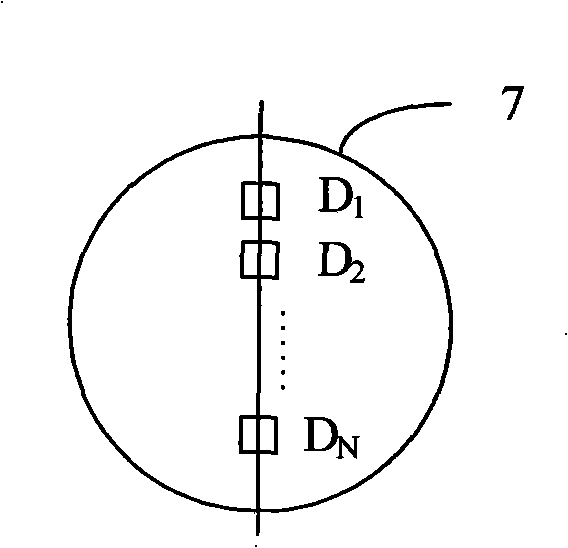

[0059] Such as figure 1 As shown, the sample cell 2 is set between the light source 1 and the dispersive element 4, and a slit 3 is set between the sample cell 2 and the dispersive element 4, and a programmable MOMES spatial light modulator is set on the optical diffraction line of the dispersive element 4 Area array 6 (may also adopt linear array stitching), and an imaging lens 5 is arranged between the dispersive element 4 and the programmable MOMES spatial light modulator area array 6, and the programmable MOMES spatial light modulator area array 6 is controlled by applying a driving voltage Modulation is performed, and several separate single detectors 7 for different wavebands are set at the focal plane of the imaging lens 5 (in conjunction with referring to Figure 1A , as required by the detector D 1 、D 2 ......D N Composition, respectively corresponding to a plurality of dispersion elements). When working, the light emitted by the light source 1 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com