Radiating unit and semiconductor package having the same

A heat dissipation unit and package technology, applied in semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve problems such as uneven flat parts, crushing chip 12 circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

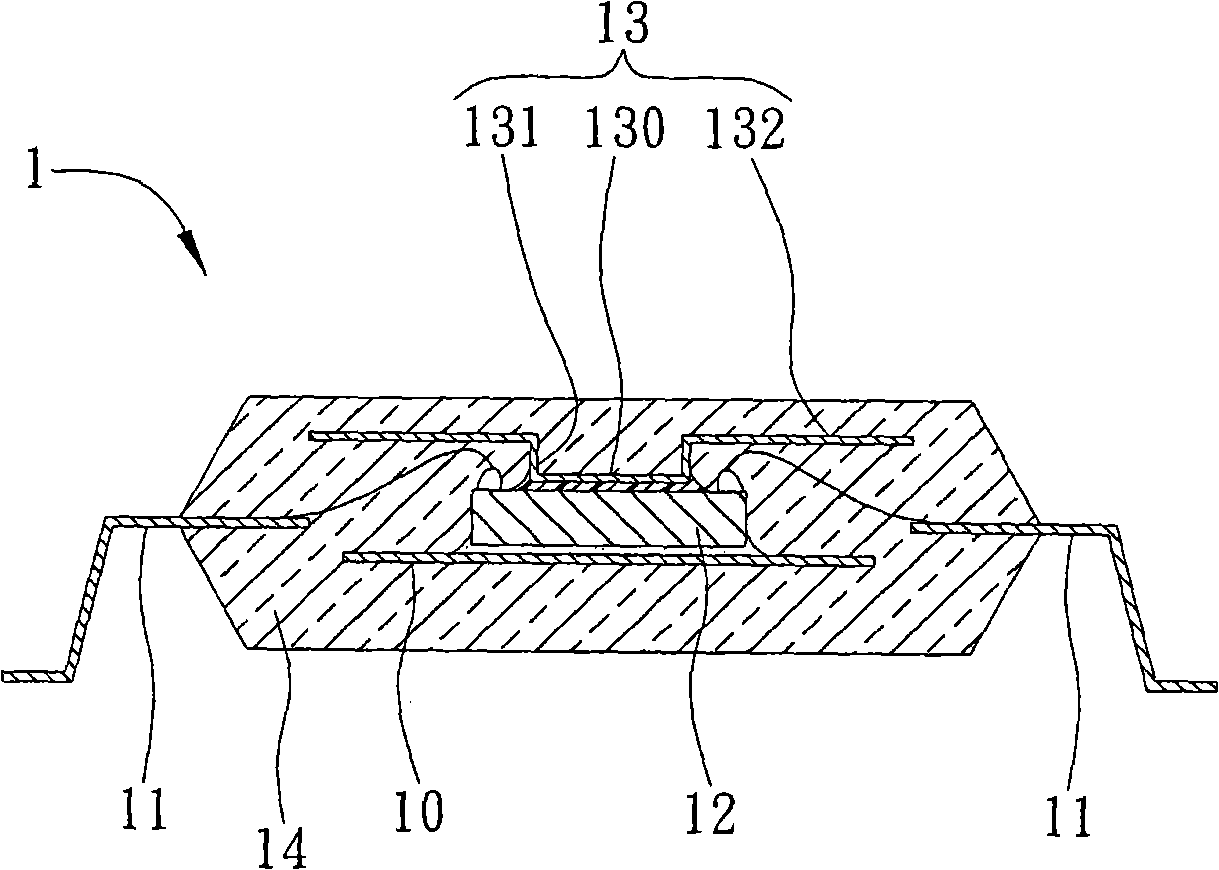

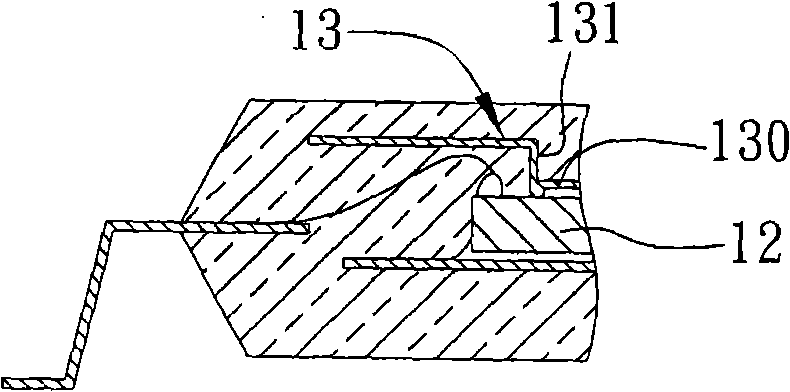

[0047] Please refer to Figure 2A to Figure 2D , is a schematic diagram showing the first embodiment of the heat dissipation unit and the semiconductor package of the present invention.

[0048] Please refer to FIG. 2A , an electronic component 21 is placed and electrically connected on the carrier 20 to form a package semi-finished product, wherein the carrier 20 can be a substrate or a lead frame, and the electronic component 21 generates high heat during operation. The chips are electrically connected to the carrier 20 by bonding wires.

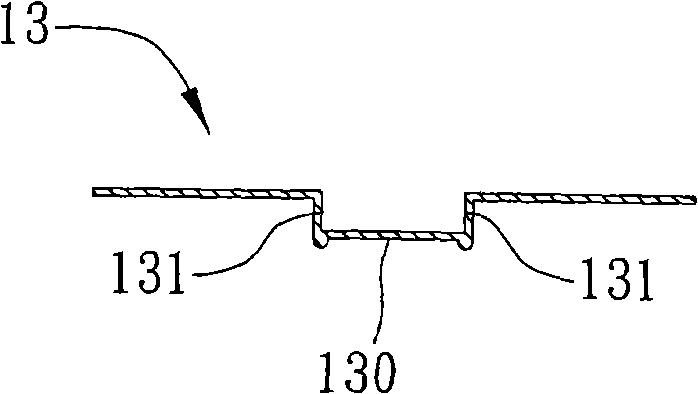

[0049] Please refer to FIG. 2B, the central area of the electronic component 21 can be connected with a heat dissipation unit 22, the heat dissipation unit 22 includes a flat part 220 attached to the top of the electronic component 21, connected to the side of the flat part 220 and facing An extension 221 extending away from the electronic component 21, and a heat dissipation portion 222 connected to the extension 221 and extending outw...

no. 2 example

[0058] see Figure 3A and Figure 3B , is a three-dimensional schematic diagram showing the second embodiment of the heat dissipation unit of the present invention. This embodiment is substantially the same as the previous embodiment, but the difference is that the stress relief part 223 of this embodiment is a mausoleum located at the junction of any two extension parts 221 The line extends to the strip-shaped slot at the corner end of the mausoleum line to prevent the stress from concentrating on the mausoleum line and deform the mausoleum line, so as to ensure that the flat portion 220 of the heat dissipation unit 22 remains flat.

[0059] Compared with the prior art where the chip is electrically connected to the substrate by wire bonding, a heat transfer element must be used to connect the heat sink exposed to the encapsulant, which increases the cost of the manufacturing process and may damage the chip during the molding process. Risk, the heat dissipation unit 22 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com