Controlled stamper machine

A stamping machine and stamping technology, applied in printing, electrical program control, program control in sequence/logic controllers, etc., can solve the problems of inability to use steel stamps, slow printing speed, and high cost, and achieve fast stamping speed, Simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

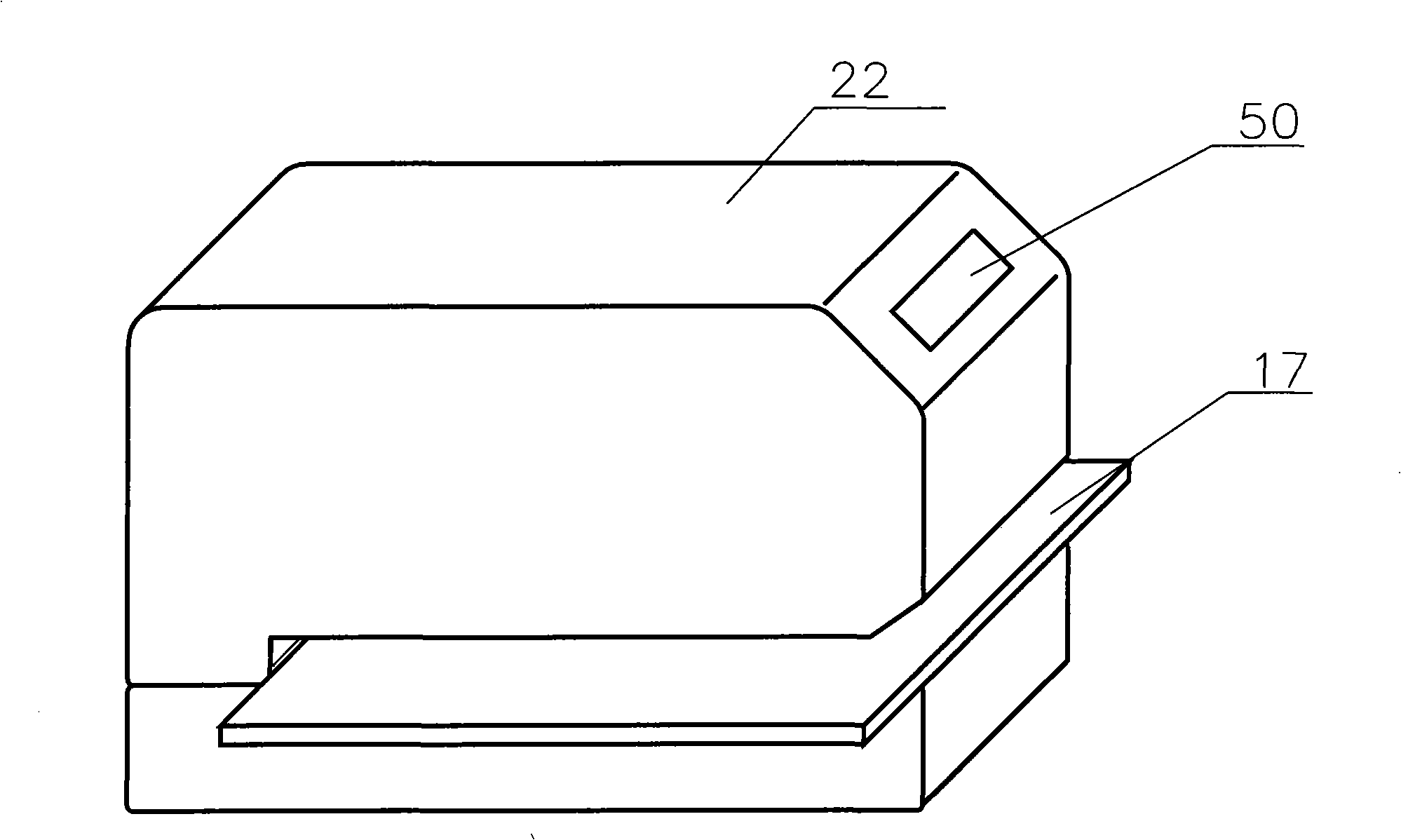

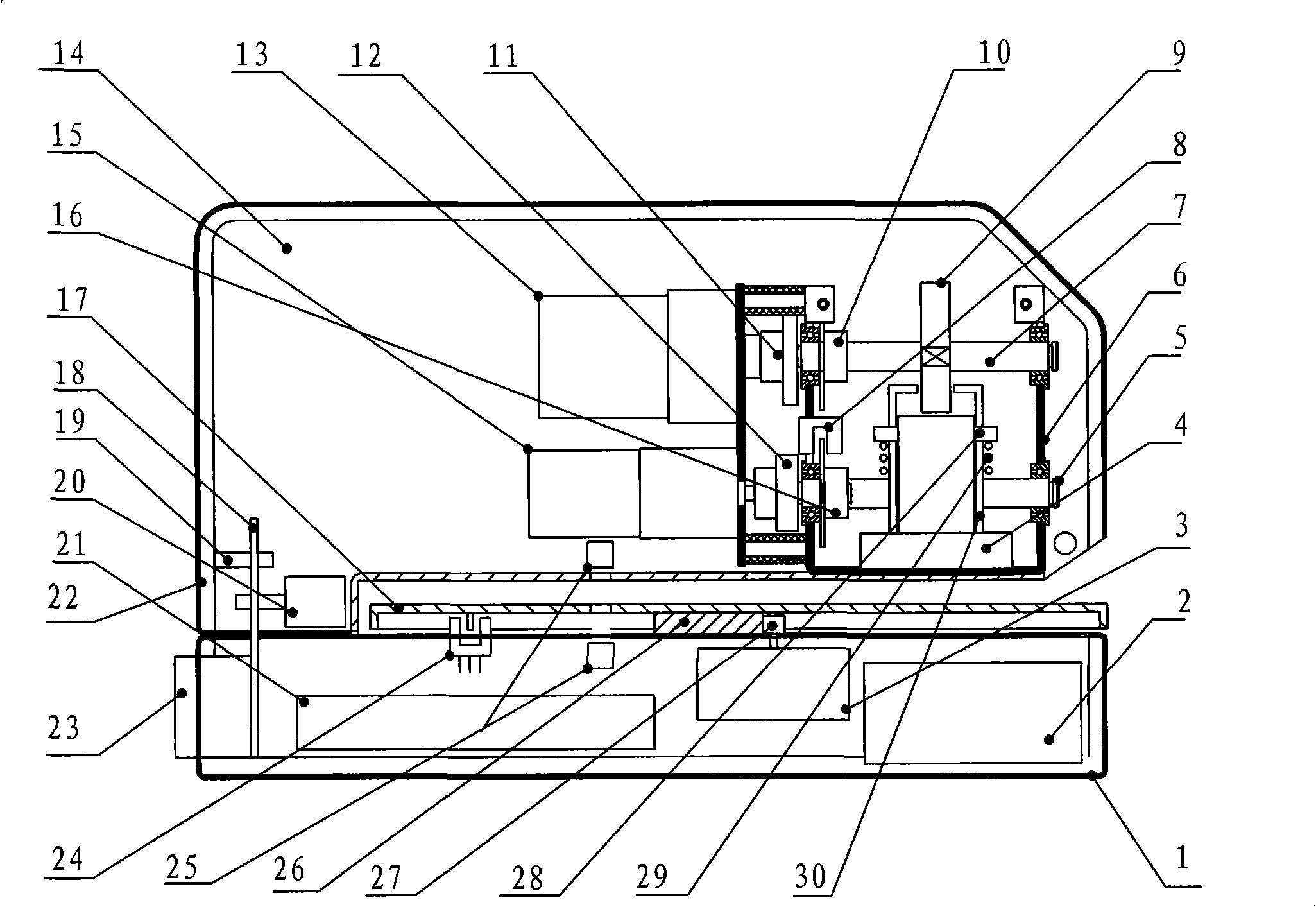

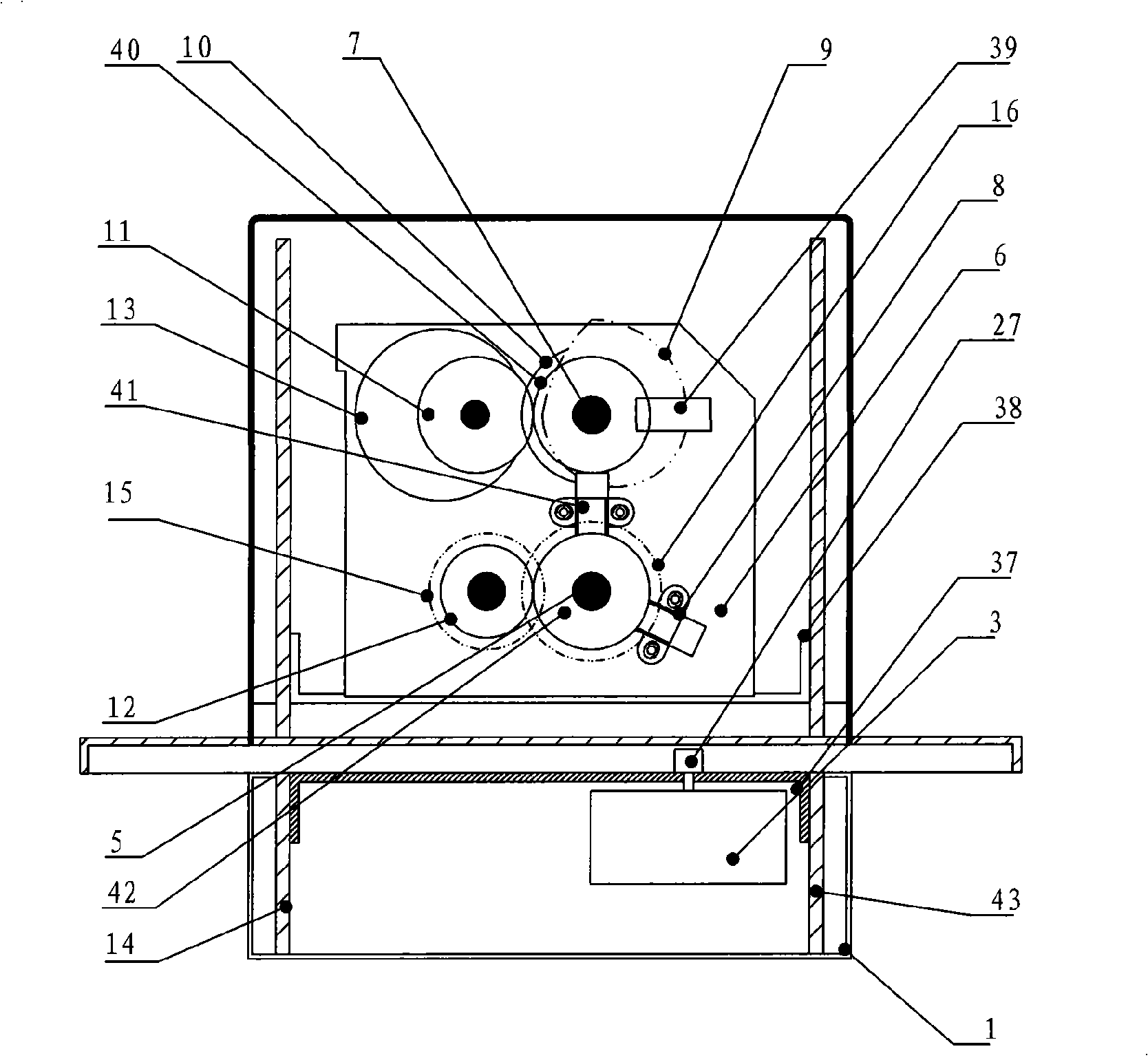

[0033] Referring to the attached picture:

[0034] Controlled seal of the present invention comprises a totally enclosed cabinet (casing is made up of upper cover 1, base 2,) has in the cabinet:

[0035] A control main board 21 containing a central processing unit, which has an interface connected to an external PC;

[0036] The electronic door lock 23 of the cabinet, the door lock 23 includes an electromagnet 20 that controls the door lock switch, and the electromagnet 20 is controlled by the central processing unit 21;

[0037] A frame is made up of side plates 14,43 support plates 37,38, and a seal movement is installed on the frame;

[0038] There is a stamp assembly driving mechanism controlled by the central processing unit 21 on the frame;

[0039] A ink-on mechanism controlled by the central processing unit 21;

[0040] A file input mechanism controlled by the central processing unit 21;

[0041] The motor 15 and the gear transmission mechanism that provide power f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com