Double-acting elastic side bearing

A double-acting, elastic technology, applied in the direction of the device that moves relatively laterally between the undercarriage and the bogie, can solve problems such as poor serpentine instability, excessive sliding friction and turning resistance torque, and affecting vehicle curve passing performance, etc. Achieve the effects of improving wear resistance, improving frictional rotation constraint, improving critical speed and running stability

Inactive Publication Date: 2008-10-22

CRRC HARBIN VEHICLES CO LTD

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the upper and lower side bearings of the rigid sliding side bearings contact, it will cause excessive sliding friction turning resistance moment between the bogie and the car body, which will seriously affect the curve passing performance of the vehicle

Although the slewing resistance of the bogie with rigid roller side bearings is much smaller than the slewing resistance moment of the bogie equipped with rigid sliding side bearings, the side bearings have poor resistance to serpentine instability when the vehicle running speed increases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

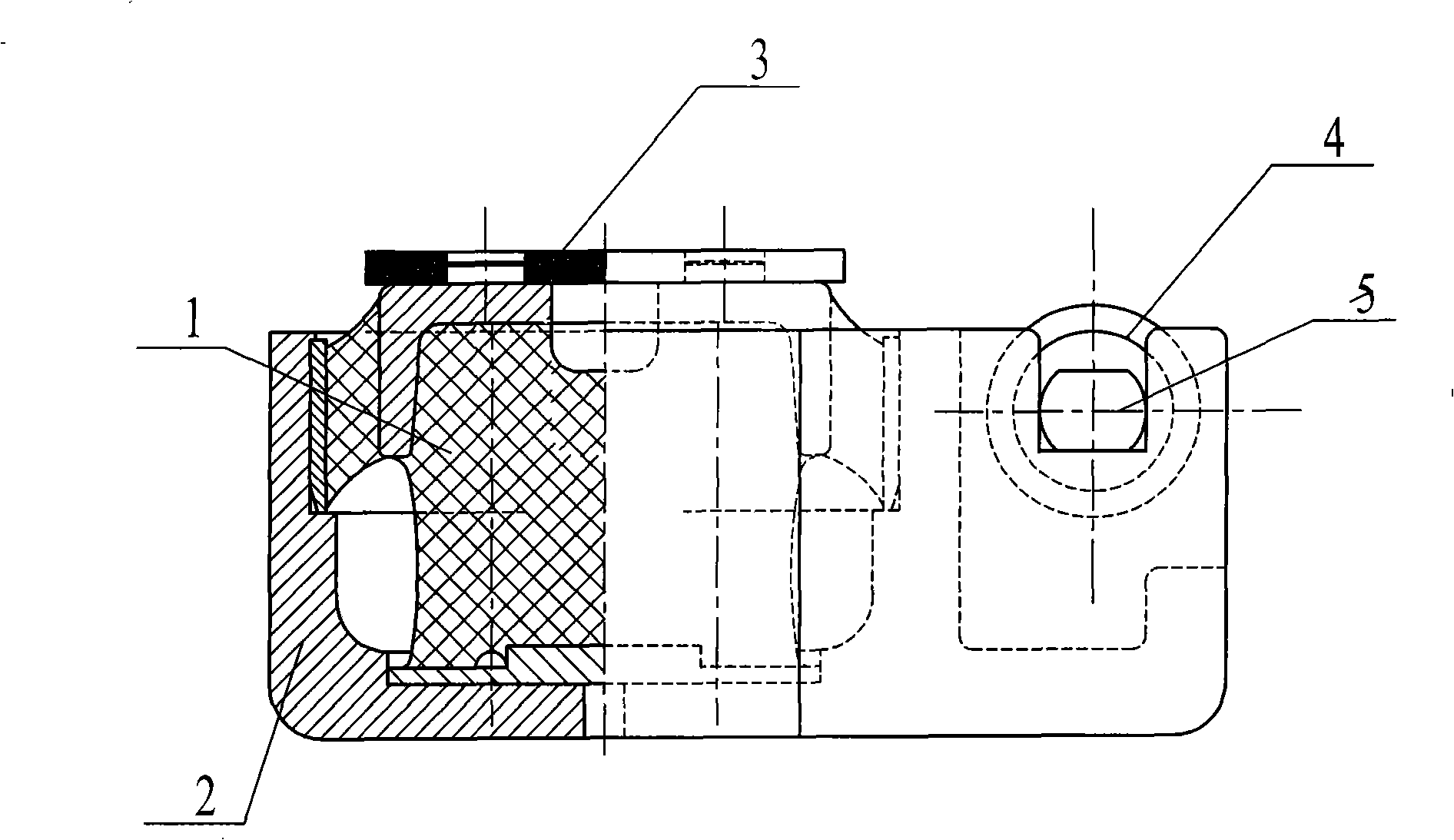

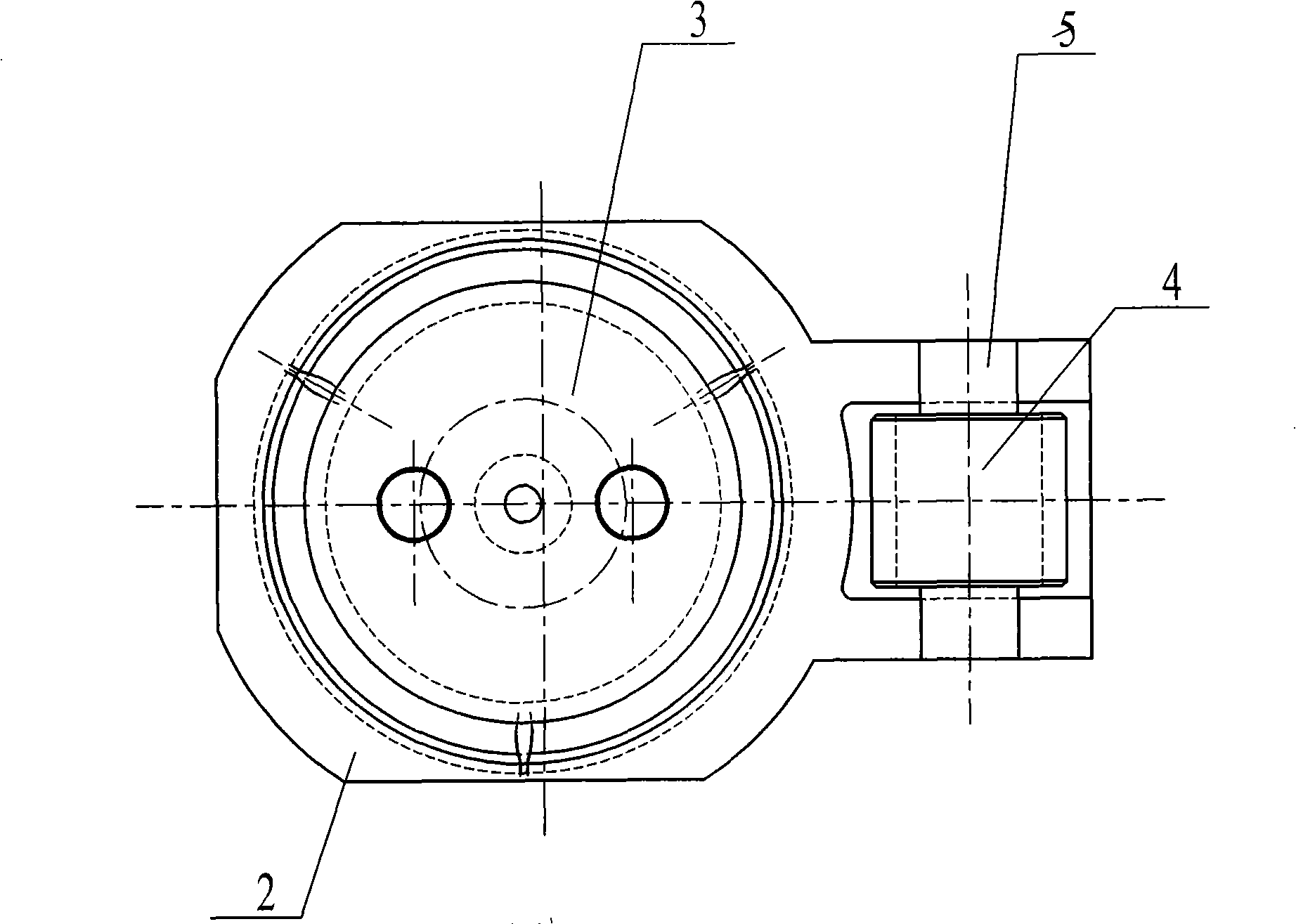

The invention relates to a dual-function elastic side bearing. The contact of the upper side bearing and lower side bearing of a rigid sliding side bearing can cause too large sliding friction steering resistance moment between a turning frame and a vehicle body, which can seriously affect the curve negotiating performance of vehicle. The dual-function elastic side bearing of the invention comprises a side bearing seat (2), an elastic side bearing body (1) positioned in the side bearing seat, a roller shaft (5) arranged in the side bearing seat, rollers (4) positioned at the roller shaft and a side bearing wearing plate (3) arranged at the upper part of the elastic side bearing body; clearance is left between the side bearing wearing plate and the rollers. The dual-function elastic side bearing is used for raising speed of 210t depressed center flat vehicle and 250t depressed center flat vehicle.

Description

Double acting elastic side bearing Technical field: The invention relates to a double-acting elastic side bearing for railway long cargo flat cars. Background technique: In the past, the side bearings used in large trucks were rigid sliding side bearings, rigid roller side bearings and constant contact elastic side bearings. When the upper and lower side bearings of the rigid sliding side bearings are in contact, an excessive sliding friction turning resistance moment will be generated between the bogie and the car body, which will seriously affect the curve passing performance of the vehicle. Although the slewing resistance of the bogie with rigid roller side bearings is much smaller than the slewing resistance moment of the bogie equipped with rigid sliding side bearings, the side bearings have poor resistance to serpentine instability when the vehicle speed increases. Invention content: The object of the present invention is to provide a double-acting elastic side b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B61F5/14

Inventor 阴雷季金刘晓林

Owner CRRC HARBIN VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com