Chute type light steel keel assembled house

A technology of light steel keel and combined house, which is applied in the direction of construction and building structure, can solve the problems of difficult demolition, large amount of construction waste, and large amount of engineering, and achieves improved safety in use, good overall structure, and improved engineering speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

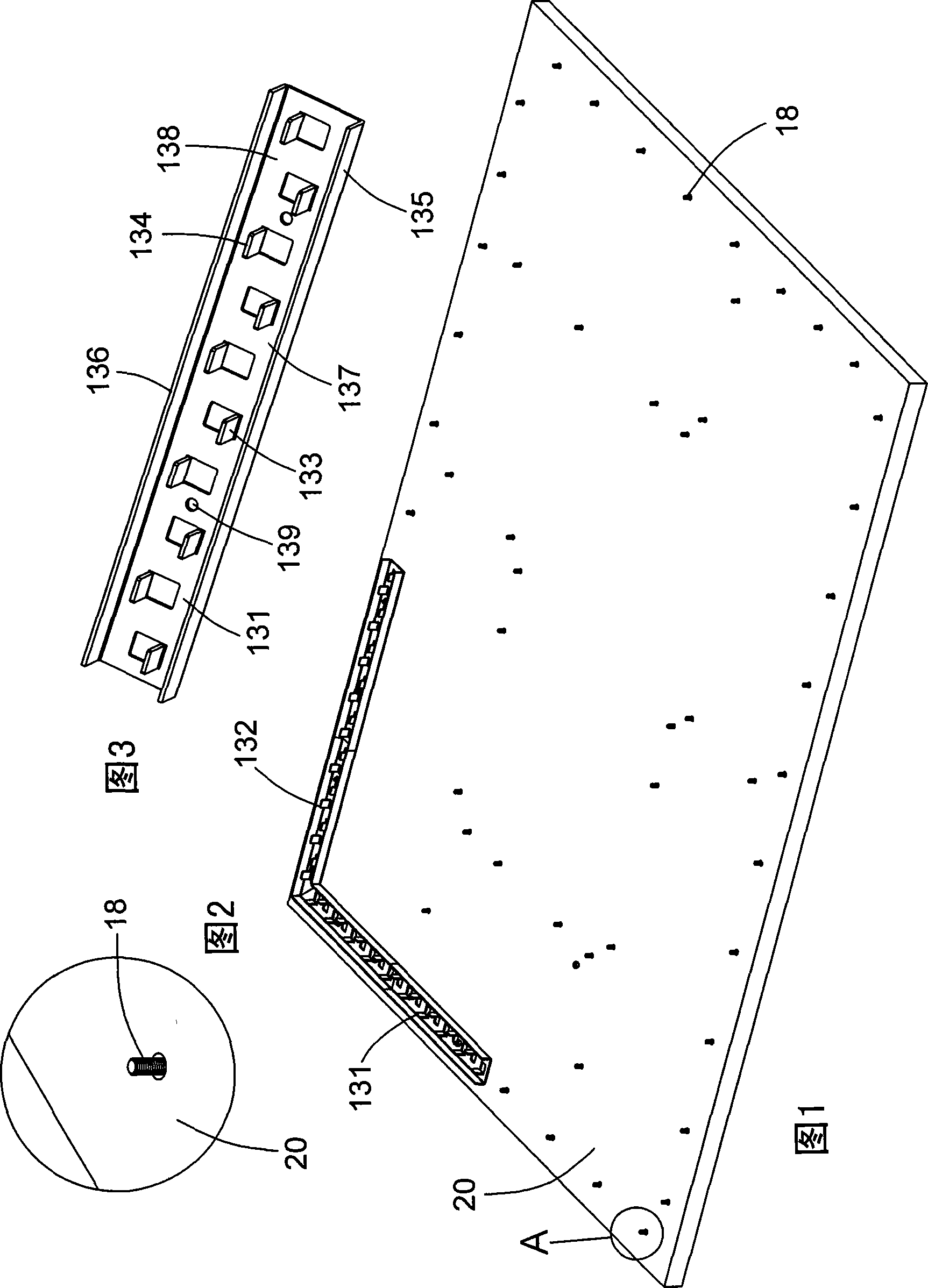

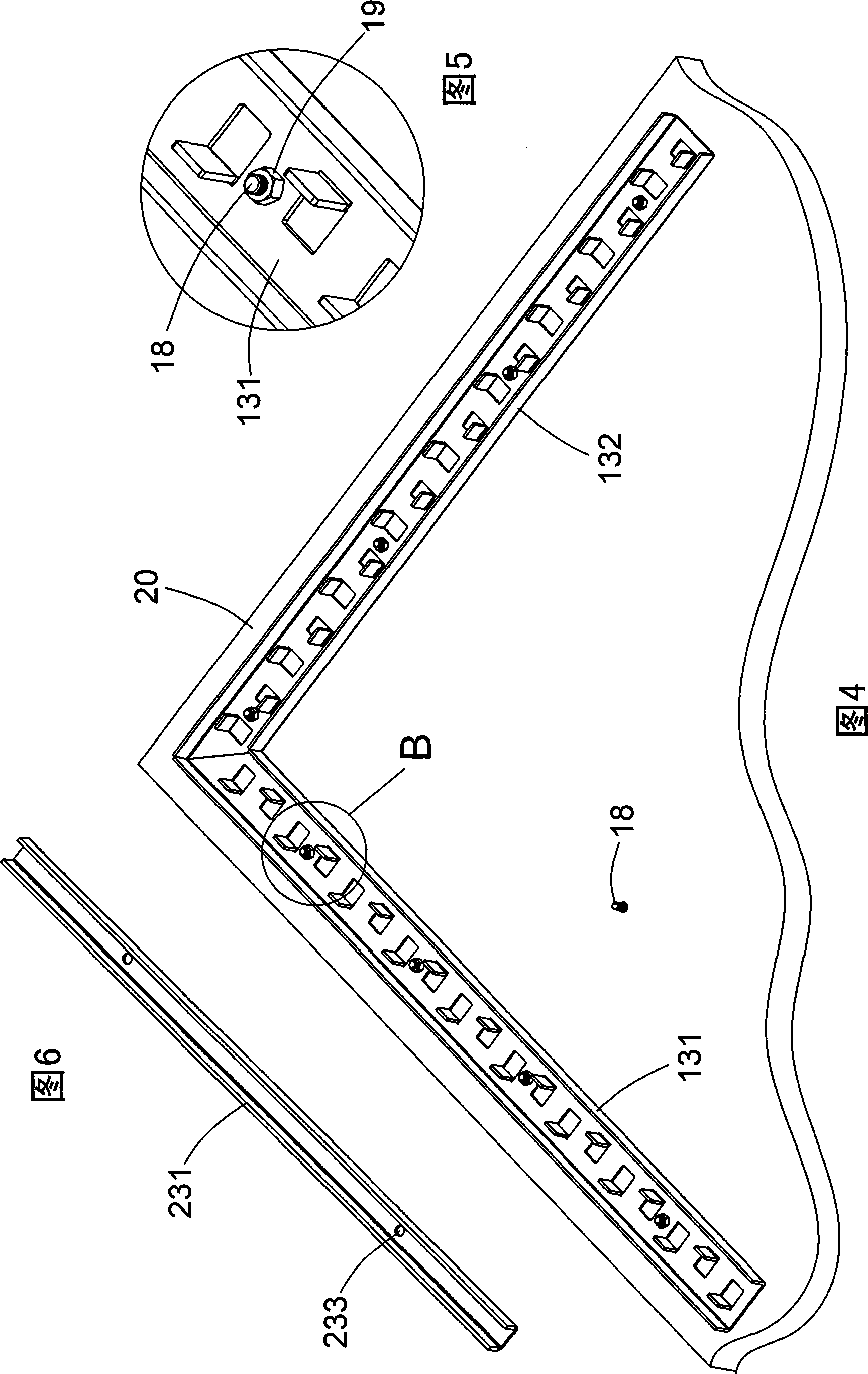

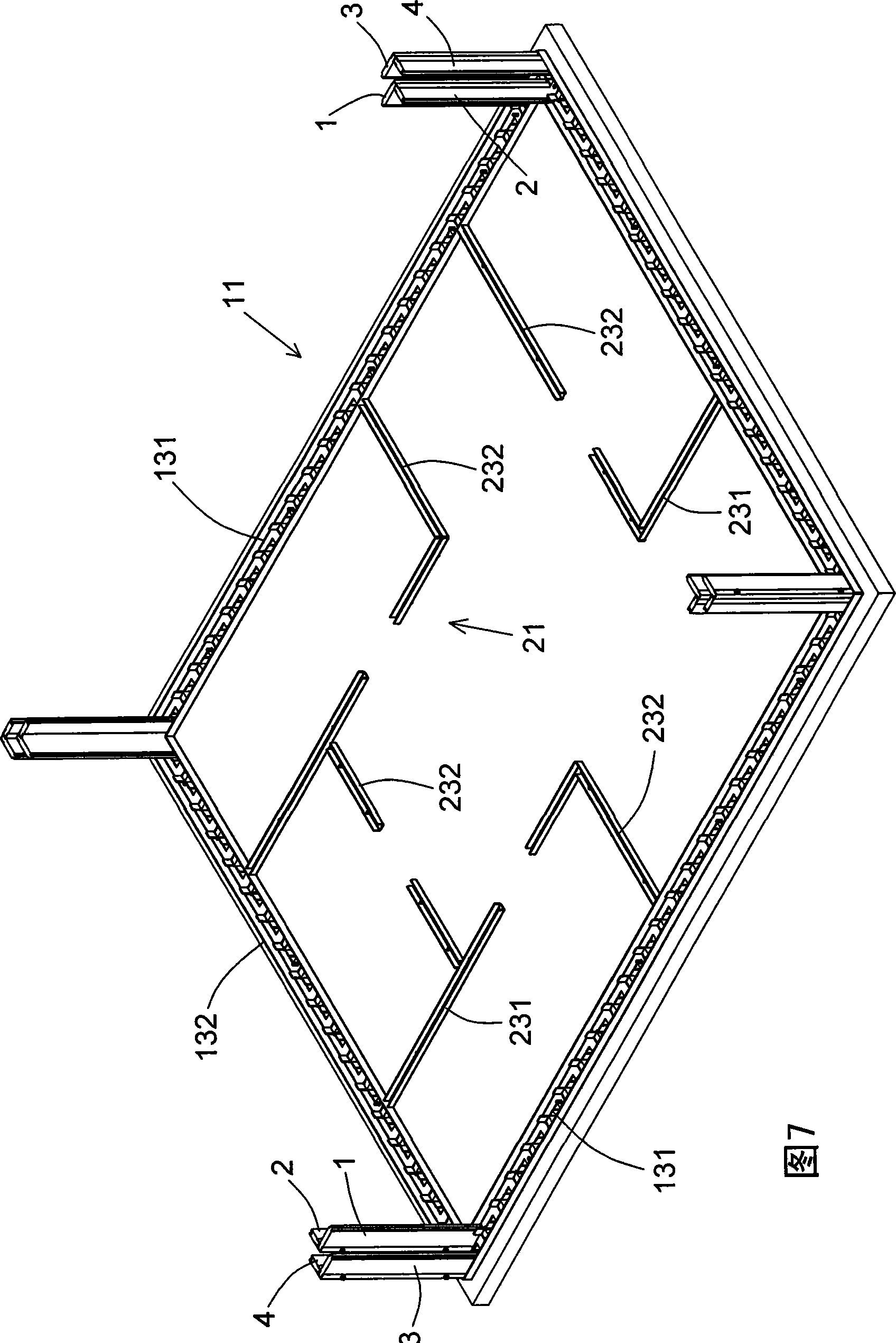

[0070] The present invention is a slideway type light steel keel composite house, which is composed of one or two or more layers, and each layer of the house has a wall, a partition wall and a roof; please refer to figure 1 , figure 2 ,image 3, Figure 4 , Figure 5 , Figure 6 , Figure 7 The bottom frame 11 and the bottom frame 21 of the first floor of the house are all connected to the foundation 20 of the house by anchor bolts, and the foundation of the first floor of the house is the foundation. The walls of each floor of the house are supported by the bottom frame 11 and the top frame 12. The bottom frame 11 is spliced by multiple horizontal and vertical lower rails 131, 132. The bottom frame 11 is the same as the outline of the house, and the lower rails are provided with openings. The upward track; the lower track can be a single track or a double track. Please refer to Fig. 3, in the present embodiment, the lower guide rail is made of grooved steel rail, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com