Outer circulation dissipation type air wave refrigerating device

A gas wave refrigerator and external circulation technology, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of equipment safety hazards, refrigeration efficiency decline, and large machine size, and achieve high reliability, high efficiency, and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

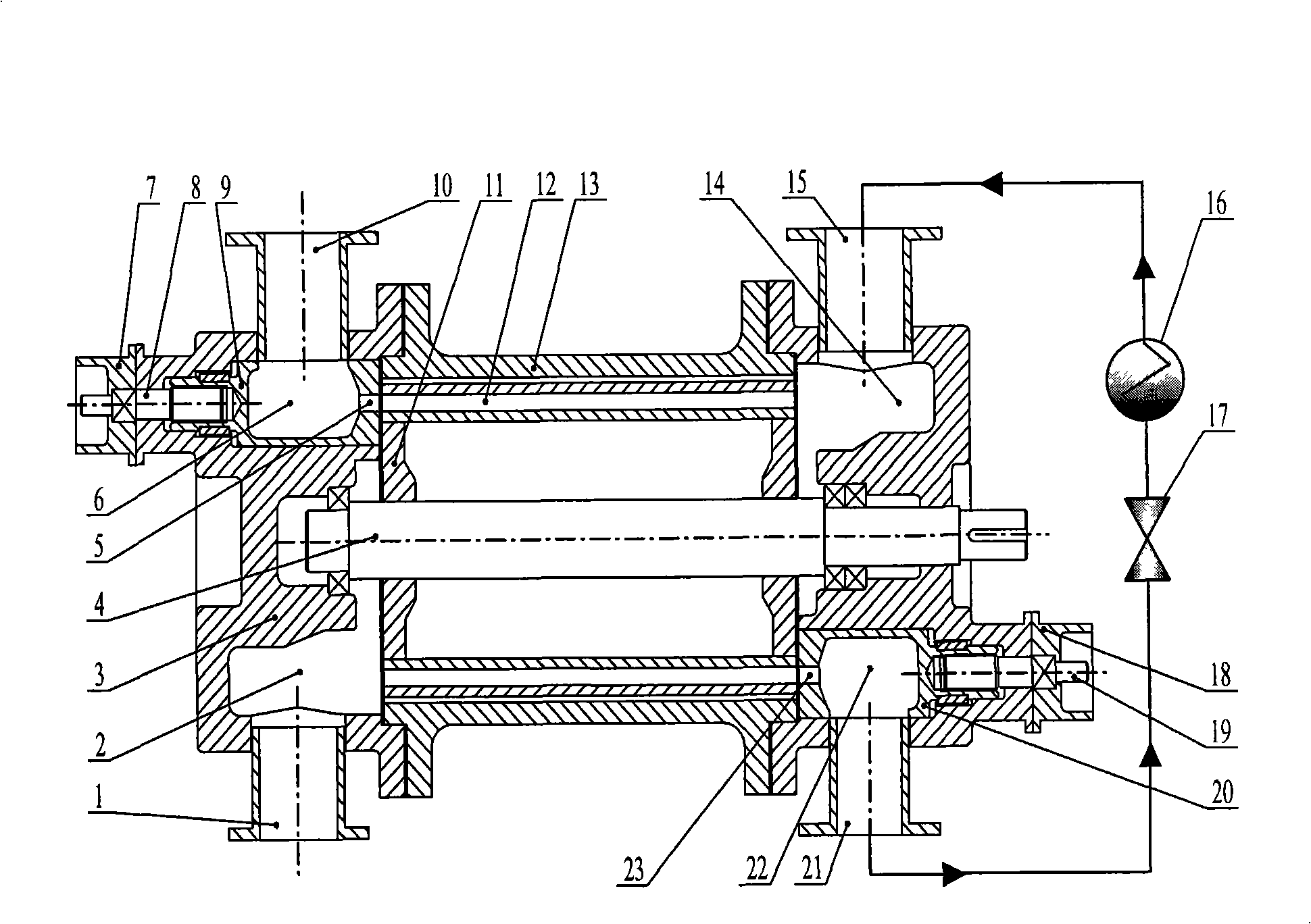

[0017] A typical embodiment of the external circulation dissipation refrigerator of the present invention is as follows:

[0018] The external circulation dissipative air wave refrigerator is mainly composed of the body 3, the main shaft 4, the drum 11, the external dissipation channel port 23, the receiving pipe 12, the shell 13, the inlet and exhaust ports 10, 1, the inlet and exhaust chambers 6. 2. External dissipation inlets 21, 15, external dissipation chambers 22, 14, external dissipation equipment-heat recovery device 16 and external dissipation equipment-pressure throttling or recovery device 17, the nozzle and the receiving pipe are composed of The dynamic and static relationship of the rotary drum 11 is completely reversed, the jet nozzle 5 is stationary, and the circumferential surface of the drum 11 is embedded with a circle of uniformly distributed receiving pipes 12, and the number of receiving pipes 12 is 30 to 280. Each receiving tube 12 rotates with the drum 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com