Lens laser focus-measuring device

A lens and laser technology, applied in the direction of testing optical performance, can solve problems such as difficult to ensure accurate measurement and prone to errors in measurement, and achieve the effects of simplifying calculations, reducing errors, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

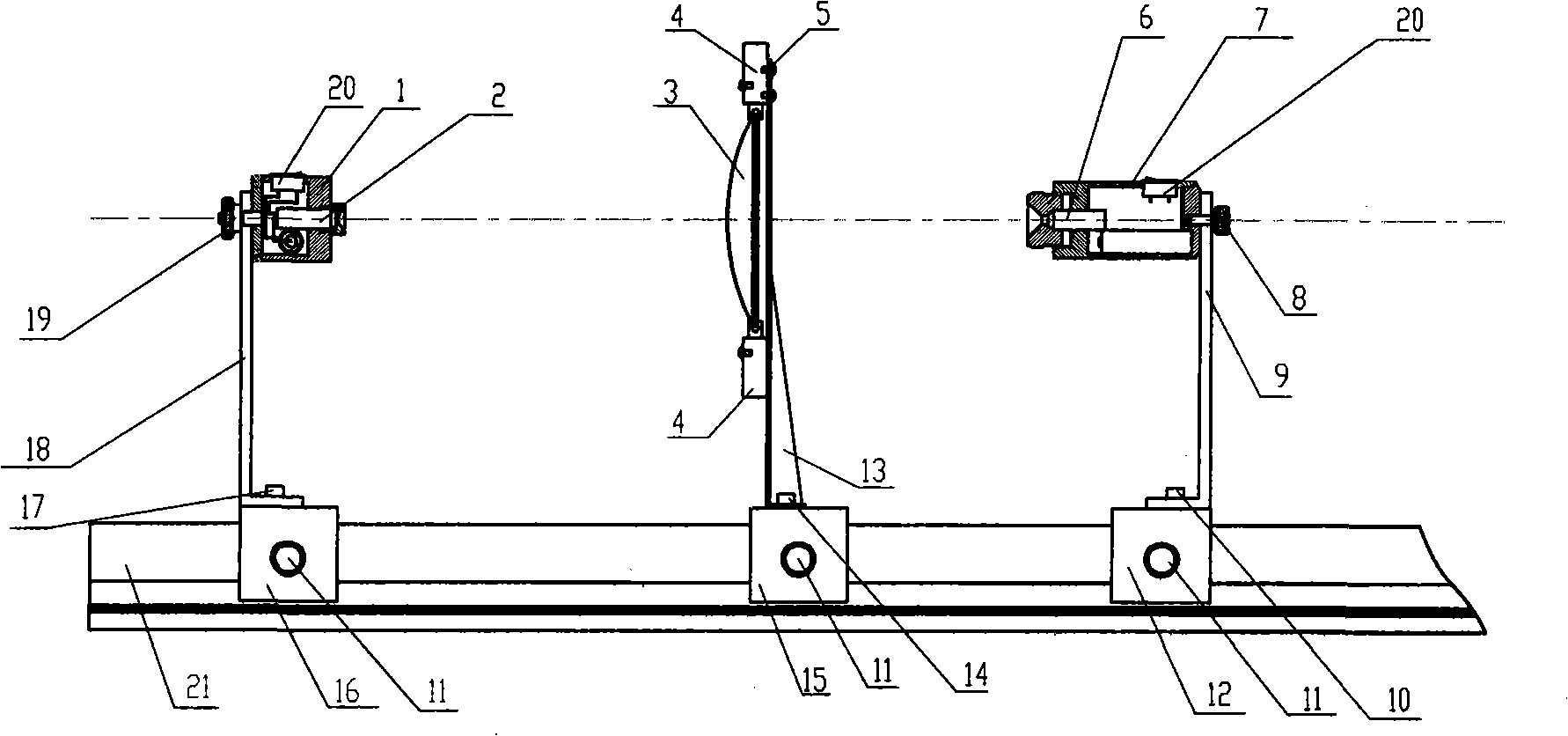

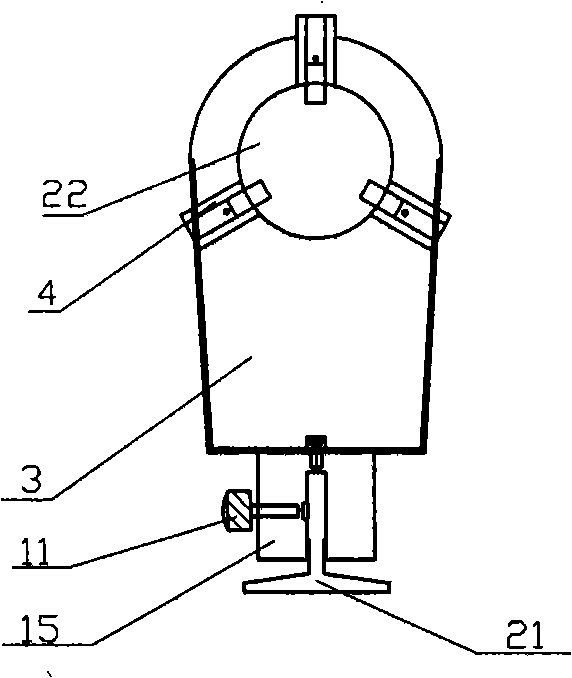

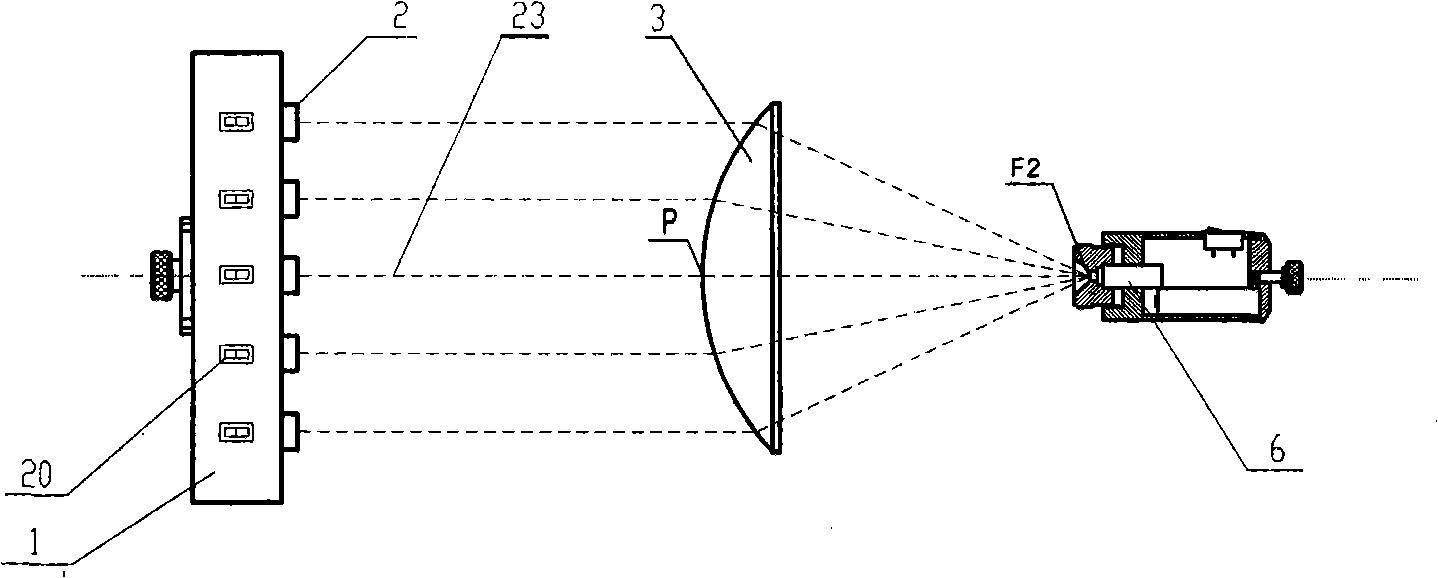

[0018] Figure 1 to Figure 3 It is an embodiment of the lens laser focus measurement device of the present invention, which includes a guide rail 21 and three sliding seats installed on it, a first sliding seat 12, a second sliding seat 15 and a third sliding seat 16, one side of each sliding seat All are equipped with fixing buttons 11, which can respectively fasten the corresponding sliding seat to the guide rail or loosen to slide, so as to facilitate the adjustment of the position of the sliding seat. The third sliding seat 16 is provided with an L-shaped bracket 18, the L-shaped bracket 18 is screwed to the sliding seat with screws 17, and the upper end of the L-shaped bracket 18 is equipped with a laser transmitter assembly 1, which is used for The fastening button 19 is fixedly connected to the L-shaped bracket 18, and a laser 2 is installed in the laser transmitter assembly 1. In this embodiment, the laser transmitter assembly 1 is equipped with five lasers 2 and switches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com