Catalyst support and catalyst for exhaust-gas purification

A technology for catalyst carrier and exhaust gas purification, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, exhaust device, etc., and can solve problems such as sintering of precious metal particles, particle size increase, and activity reduction

Inactive Publication Date: 2008-10-22

TOYOTA JIDOSHA KK

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the particle diameter of the catalyst component is reduced, its surface energy increases, so it becomes easy to sinter with each other (sintering)

Especially in exhaust gas purification catalysts, the catalyst is exposed to high temperatures of hundreds of degrees due to the heat of the exhaust gas or the heat generated by the reaction, which tends to lead to sintering of noble metal particles, increase in particle size, and decrease in activity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

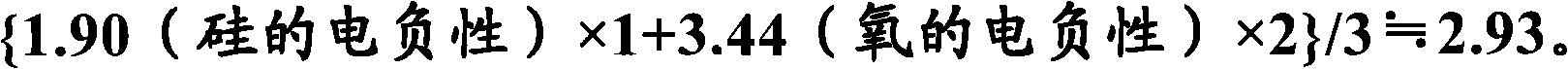

The invention provides a catalyst support which produces the excellent effect of inhibiting noble-metal catalyst particles from sintering and a catalyst for exhaust-gas purification. The catalyst support, which is for noble-metal supporting, comprises a composite oxide of: an electron-accepting element (La) which has the property of accepting an electron from a noble metal element (Pt) upon approach of or contact with the noble metal element and which does not change in valence through oxidation / reduction reactions; and other element(s) (Si). The invention also provides an exhaust-gas purification catalyst on this catalyst support for carrying noble-metal catalyst particles.

Description

Catalyst carrier and catalyst for exhaust gas purification technical field The present invention relates to a catalyst carrier for supporting noble metal catalyst particles, and an exhaust gas purification catalyst in which noble metal catalyst particles are supported on the catalyst carrier. Background technique In the case of a catalyst in which noble metal particles are supported on a carrier as a catalyst component, the noble metal particles are supported on the carrier in the form of fine particles in order to improve the activity. This is to maximize the specific surface area of the catalyst component. However, if the particle size of the catalyst component is reduced, the surface energy thereof increases, so that mutual sintering (sintering) becomes easy. Especially in exhaust gas purification catalysts, the catalyst is exposed to high temperatures of hundreds of degrees due to the heat of the exhaust gas or heat generated by the reaction, which tends to cause no...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/63B01D53/86B01D53/94B01J23/42B01J32/00F01N3/10F01N3/28

Inventor 竹岛伸一小山晃生

Owner TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com