Engagement member-equipped optical fiber cable

一种卡合部件、光缆的技术,应用在光学、光导、光学元件等方向,能够解决护套固定无法获得足够的强度等问题,达到护套固定强度提升、抑制结合强度下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

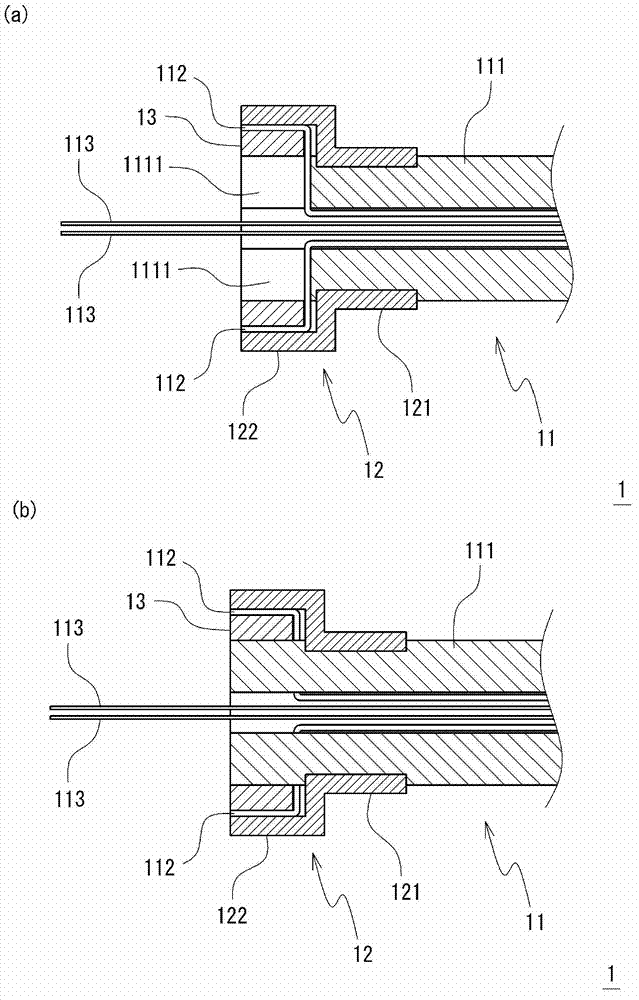

[0033]Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In the following description, the "axis direction" of each member constituting the optical cable with a fastener according to the embodiment of the present invention refers to the optical cable based on the completed state of the optical cable with a fastener according to the embodiment of the present invention. the length direction. Similarly, "front end side" refers to the side near the end of the optical cable (here, the end on the side where the engaging member is mounted); "rear end side" refers to the side away from the end of the optical cable.

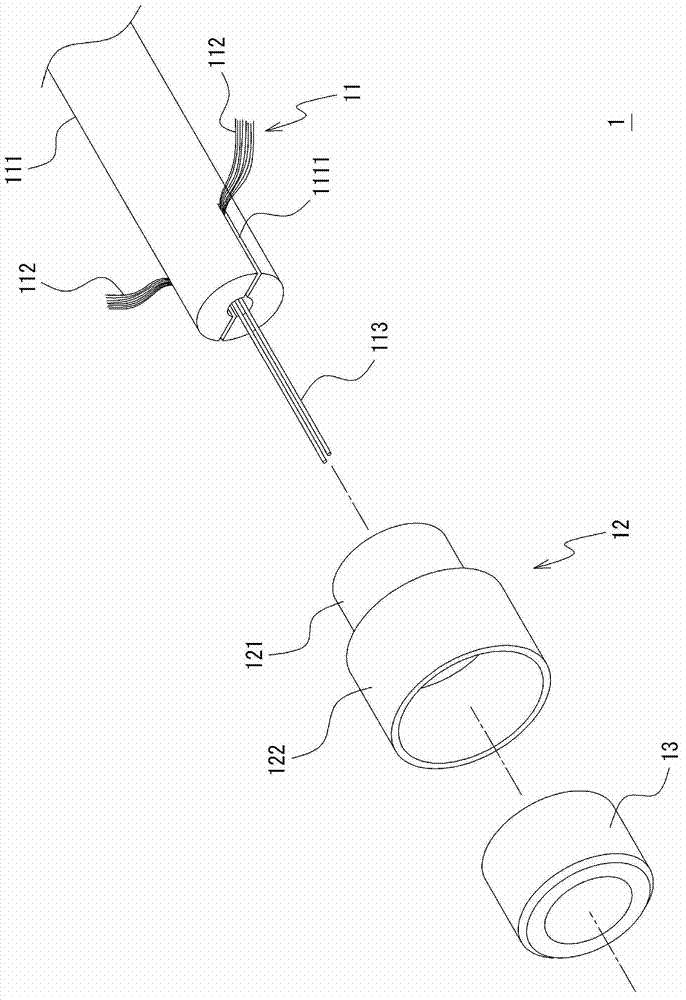

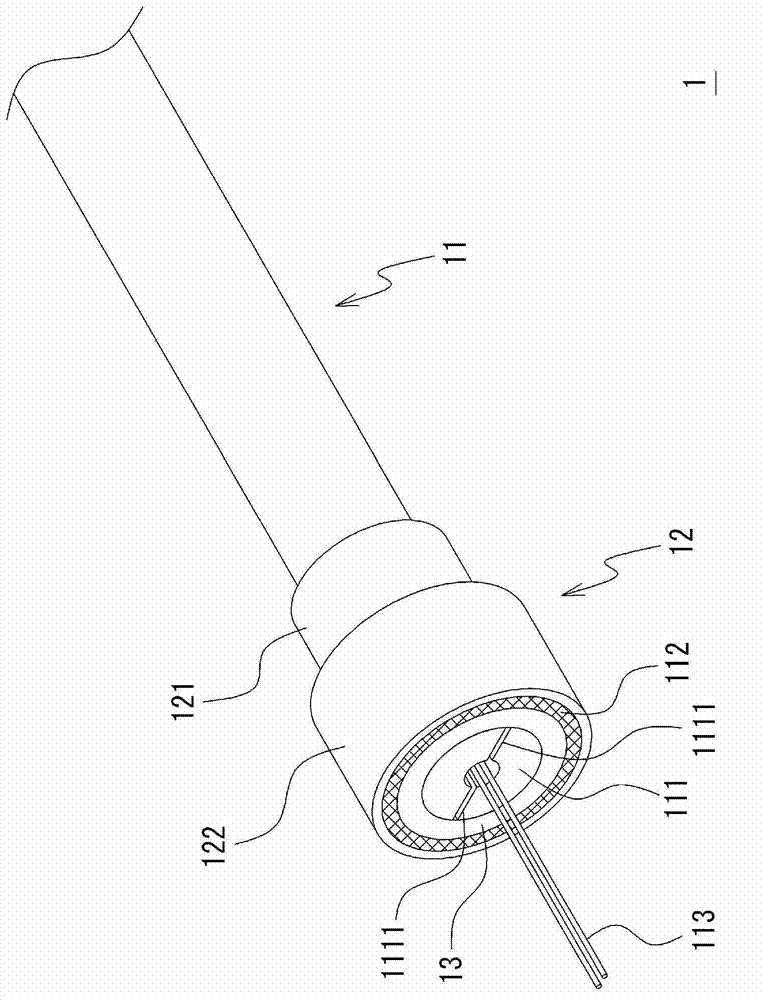

[0034] figure 1 It is an exploded perspective view showing the structure of the optical cable 1 with the engaging member according to the embodiment of the present invention. figure 2 It is an external perspective view showing the structure of the optical cable 1 with an engaging member according to the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com