Catalyst support and catalyst for exhaust-gas purification

A technology for catalyst carrier and exhaust gas purification, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, exhaust device, etc., and can solve the problems of particle size increase, easy mutual sintering, surface increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

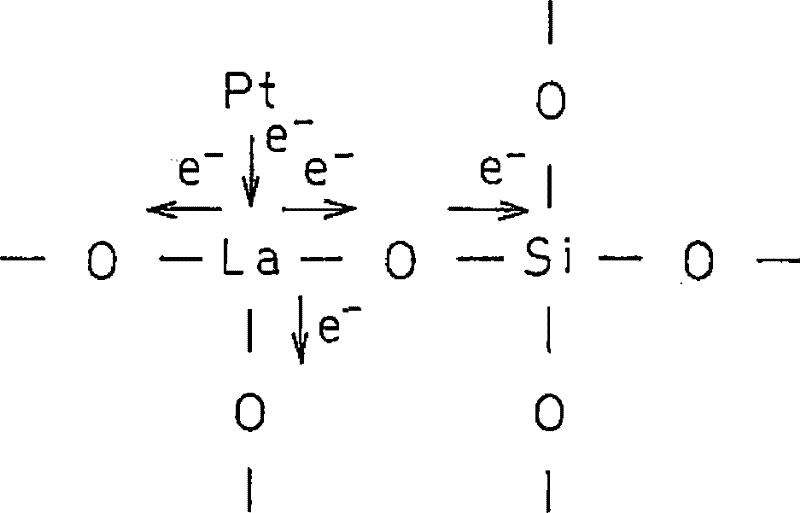

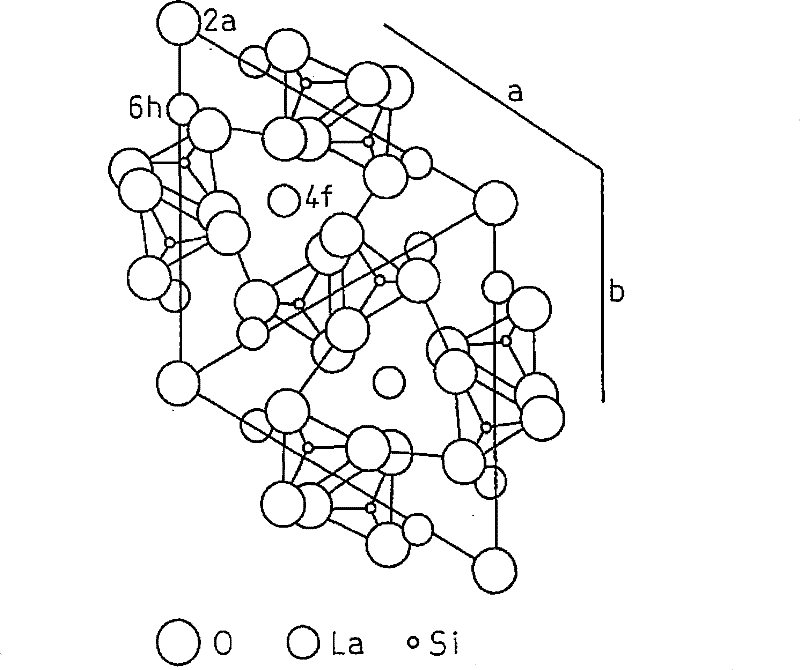

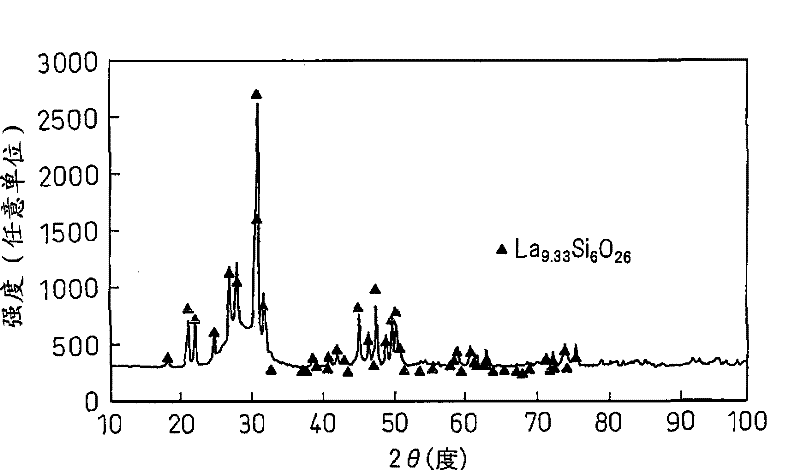

[0095] [Synthesis of Lanthanum Oxide-Silica Composite Oxide Catalyst Support of the Present Invention]

[0096] As described below, the composition of La was synthesized by microemulsion method 10 Si 6 o 27 Lanthanum oxide-silica composite oxide catalyst support.

[0097] First, as a source of lanthanum (La), 180 ml of a mixed aqueous solution of lanthanum nitrate (0.3016 mol, concentration 1.675 M) and ammonia (0.3748 mol, concentration 2.082 M) was mixed with 22.6 ml of 2-butanol until the alkyl A microemulsion was prepared by dissolving 456.9 g of surfactant BC-5.5 (trade name) in 6485 ml of cyclohexane. On the other hand, as a silicon (Si) source, an alkoxide solution in which 0.1809 mol of tetraethoxysilane (TEOS) was dissolved in 1000 ml of cyclohexane was prepared.

[0098] An alkoxide solution as a source of silicon (Si) was mixed with the microemulsion as a source of lanthanum (La), and 79.85 ml of ammonia water with a concentration of 14.8 M and 7.69 ml of distil...

Embodiment 2

[0135] In this example, the effect of the composition of the composite oxide on the effect of suppressing sintering will be described.

[0136] A plurality of lanthanum oxide-silica composite oxides with different lanthanum contents (La / (La+Si)) were prepared, each loaded with 1 wt% of platinum particles, and after calcination at 800°C in air for 2 hours, the platinum was measured. particle size. The evaluation results for the platinum (Pt) particle size are shown in Figure 4 middle. Depend on Figure 4 It was clearly confirmed that when the lanthanum content is around 50 to 70%, the particle size of the platinum particles can be kept small, and the effect of suppressing sintering is large.

[0137] Similarly, regarding the neodymium oxide-zirconia composite oxide, the influence of the neodymium content rate (Nd / (Nd+Zr)) was investigated. The supported amount of platinum particles and firing conditions are the same as those in the case of the above-mentioned lanthanum oxi...

Embodiment 3

[0140] Using zirconia sol, the lanthanum oxide-silicon dioxide composite oxide (La 10 Si 6 o 27 ) The catalyst carrier is coated on a monolith honeycomb (MonolithHoneycomb) substrate, and then 1.2g / substrate-L platinum is supported on the substrate coated with the catalyst carrier to obtain the exhaust gas purification catalyst of the present invention.

[0141] The thus obtained exhaust gas purification catalyst of the present invention was supplied with a stoichiometry gas having the following composition at 1000° C. for 2 hours, 10 hours and 20 hours, respectively, for durability. Then, for the exhaust gas purification catalyst of the present invention that has not been durable and the exhaust gas purification catalyst of the present invention that has been durable, the same stoichiometric gas is supplied while the temperature is raised, and the HC 50% purification temperature is investigated (the purification rate of HC reaches 50% % catalyst temperature).

[0142] Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electronegativity | aaaaa | aaaaa |

| electronegativity | aaaaa | aaaaa |

| electronegativity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com