Filter member

A filter component and bottom thickness technology, which is applied in the direction of filtration separation, membrane filter, and dispersed particle filtration, etc., can solve the problems of not considering the washability and sanitation measures of the filter element, the increase of manufacturing cost, and the damage to the precision of the component, so as to reduce the Steps, places to reduce buildup, high precision and quality of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

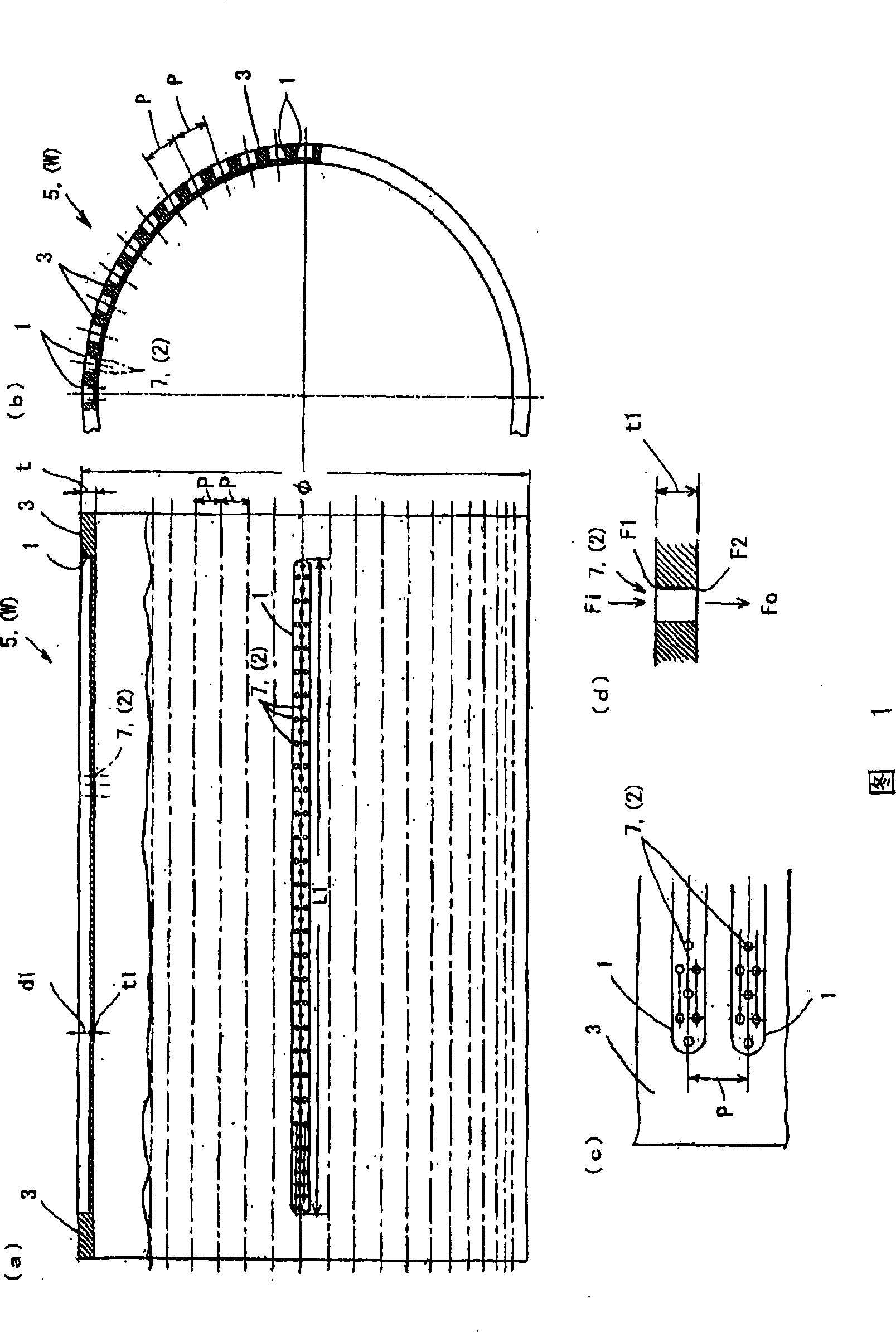

[0021] see figure 1 Example 1 will be described.

[0022] figure 1 is a drawing of a manufactured part employed in a filter element for processing food such as vegetable juice, fruit juice, etc. The groove 1 is formed at a desired position (in this embodiment, the outer surface of the cylindrical body 5 ) of the workpiece W (ie, the cylindrical body 5 ) having a thickness t and made of a single material. A plurality of continuous through holes 2 are drilled in the groove. Except for the groove 1, the rest 3 of the workpiece W has a strength maintaining function, and the workpiece as a whole is formed into an integral structure. Reference sign ф refers to the diameter of the outer surface of the cylindrical body 5 .

[0023] As a single material for the workpiece W, for example, drawn tubes made of various metals such as steel, stainless steel, and aluminum are used. A single material is machined, and the grooves 1 are formed on the outer surface of the cylindrical body 5 ...

Embodiment 2

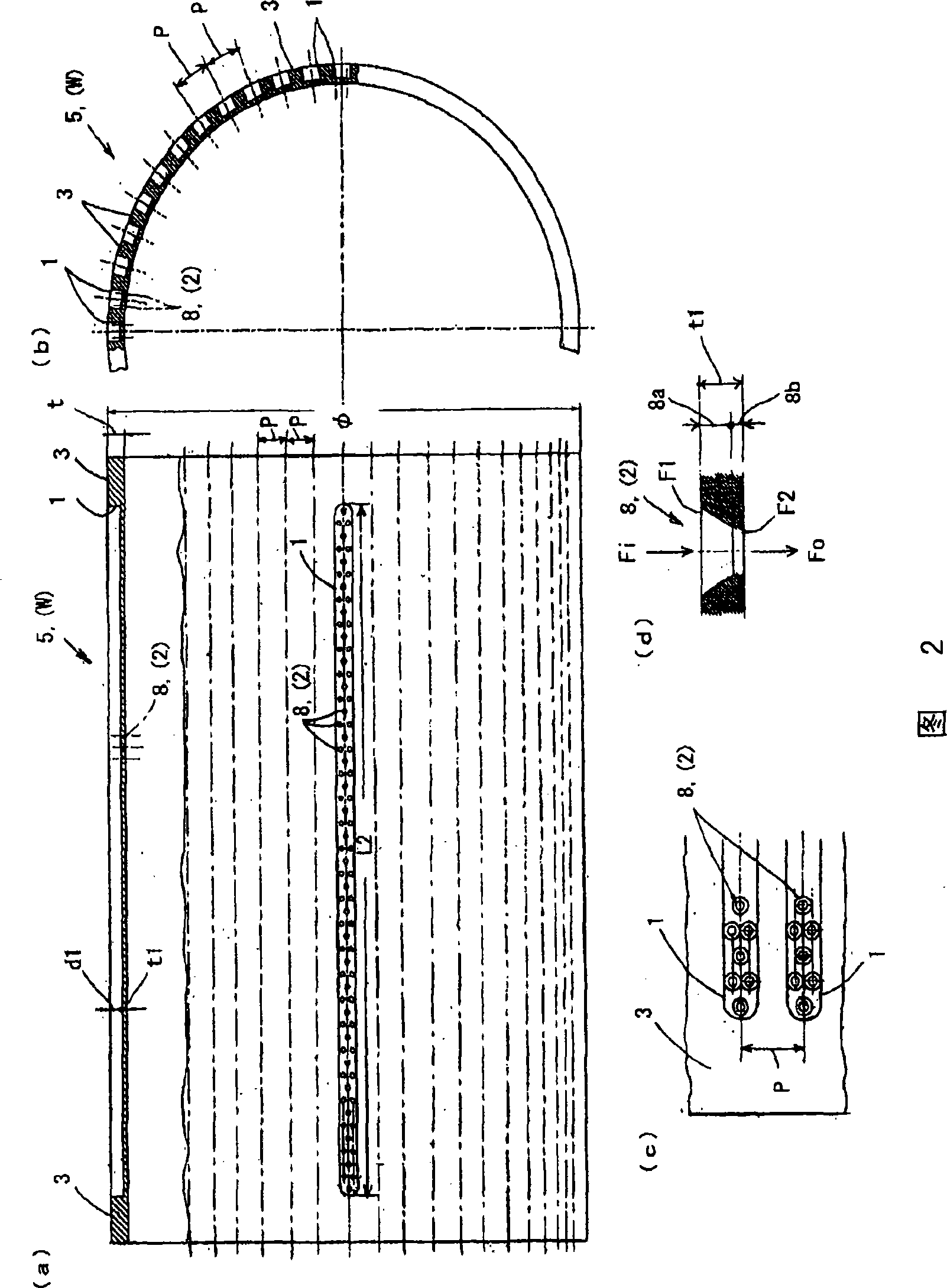

[0027] Such as figure 2 As shown, the structure of Embodiment 2 is almost the same as that of Embodiment 1 except for the shape of the through hole 2 . Here, the tapered hole 8 is formed as the through hole 2 , whereas in Embodiment 1, the straight hole 7 is formed as the through hole 2 .

[0028] Such as figure 2 As shown in (d), when the liquid to be treated flows from Fi to Fo, the liquid passes through the tapered channel from the wide opening F1 to the narrow opening F2. The tapered hole formed on the bottom of the groove having a thickness t1 is composed of a tapered portion 8a and a straight portion 8b. The reference L2 refers to the length of the groove 1 . exist figure 2 In (d), the flow direction is shown from Fi to Fo, but the flow direction can be reversed.

[0029] The cross-sectional shape of the through hole is not limited to the shape of Embodiment 1 and Embodiment 2, and the cross-section can be formed into a desired shape, such as an arc.

[0030] Si...

Embodiment 3

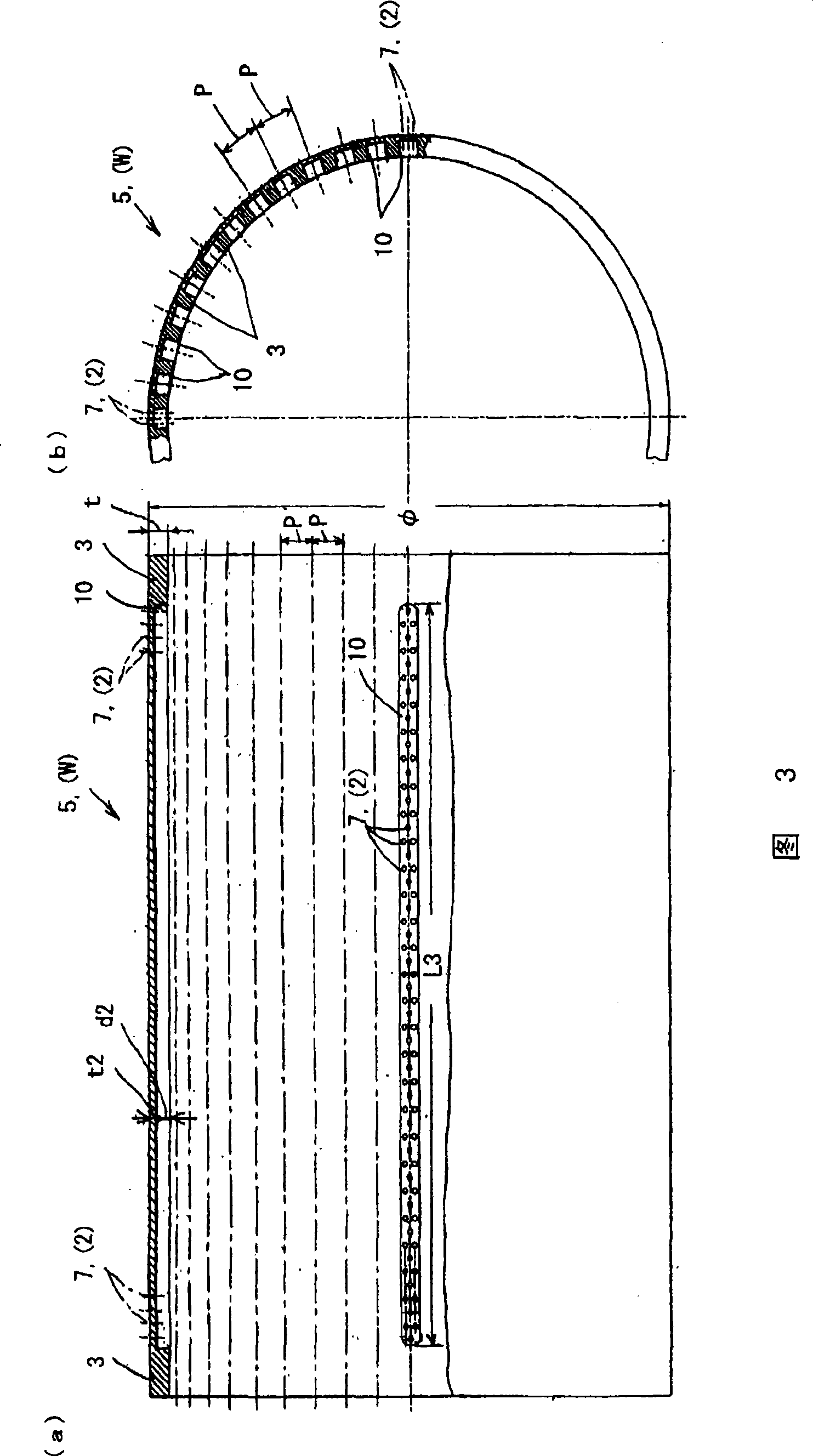

[0032] Such as image 3 As shown, in Embodiment 3, the groove 10 is formed on the inner surface of the cylindrical body 5 , whereas in Embodiments 1 and 2, the groove 1 is formed on the outer surface of the cylindrical body 5 . exist image 3 , the through hole 2 is shown as a straight hole 7 , but the through hole may be formed as a tapered hole 8 .

[0033] The thickness of the bottom of the groove 10 is t2. The depth and length of the groove 10 are d2 and L3, respectively.

[0034] In a filter member employed in a filter for food processing or fluid treatment, slits may be formed on grooves instead of through holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com