Method of manufacturing multi phase microstructured steel piece

A technology of microstructure and parts, applied in the direction of manufacturing tools, heat treatment equipment, coatings, etc., can solve problems such as difficult to control springback of formed parts, limited shape range, unpredictable part behavior, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

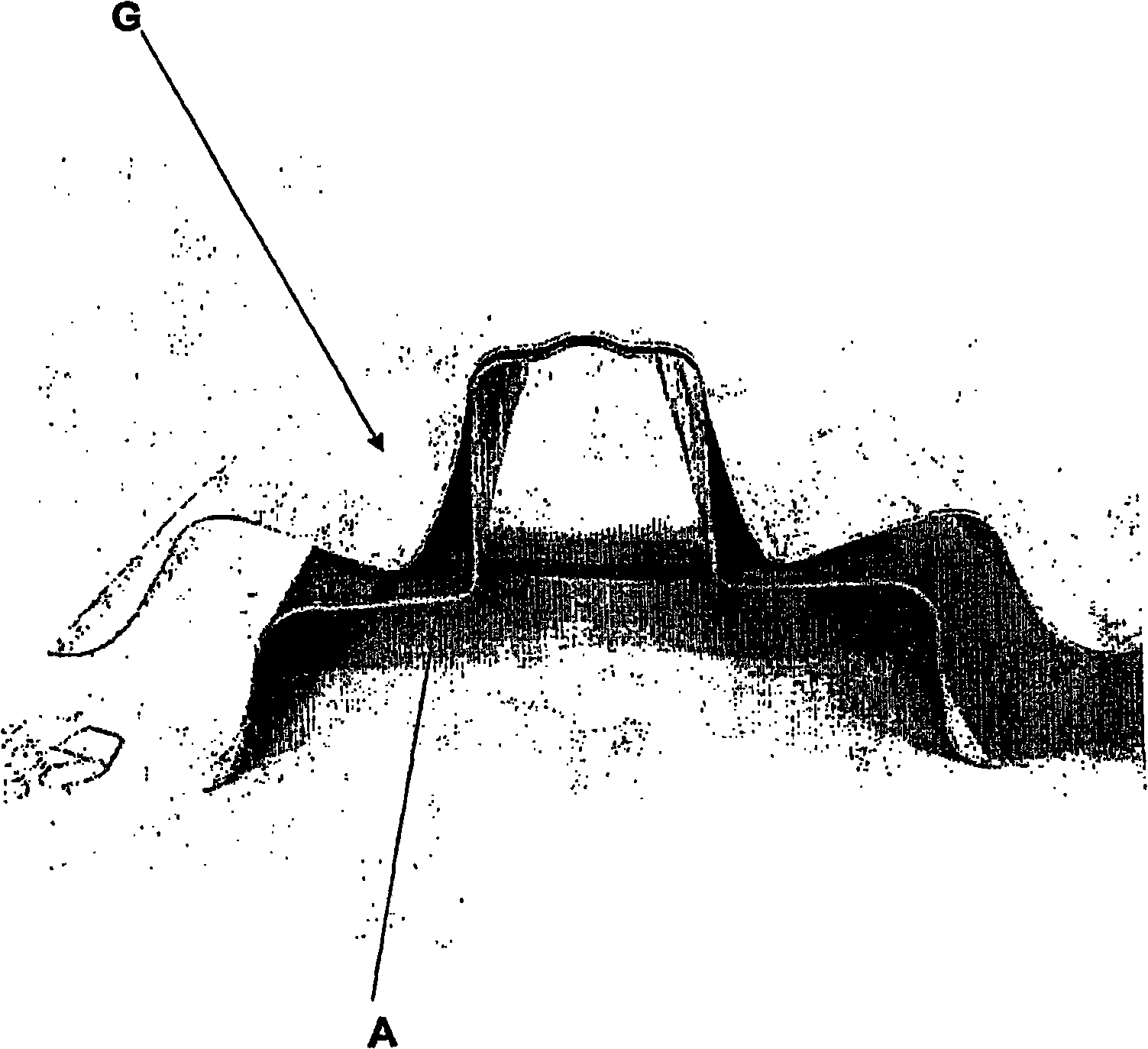

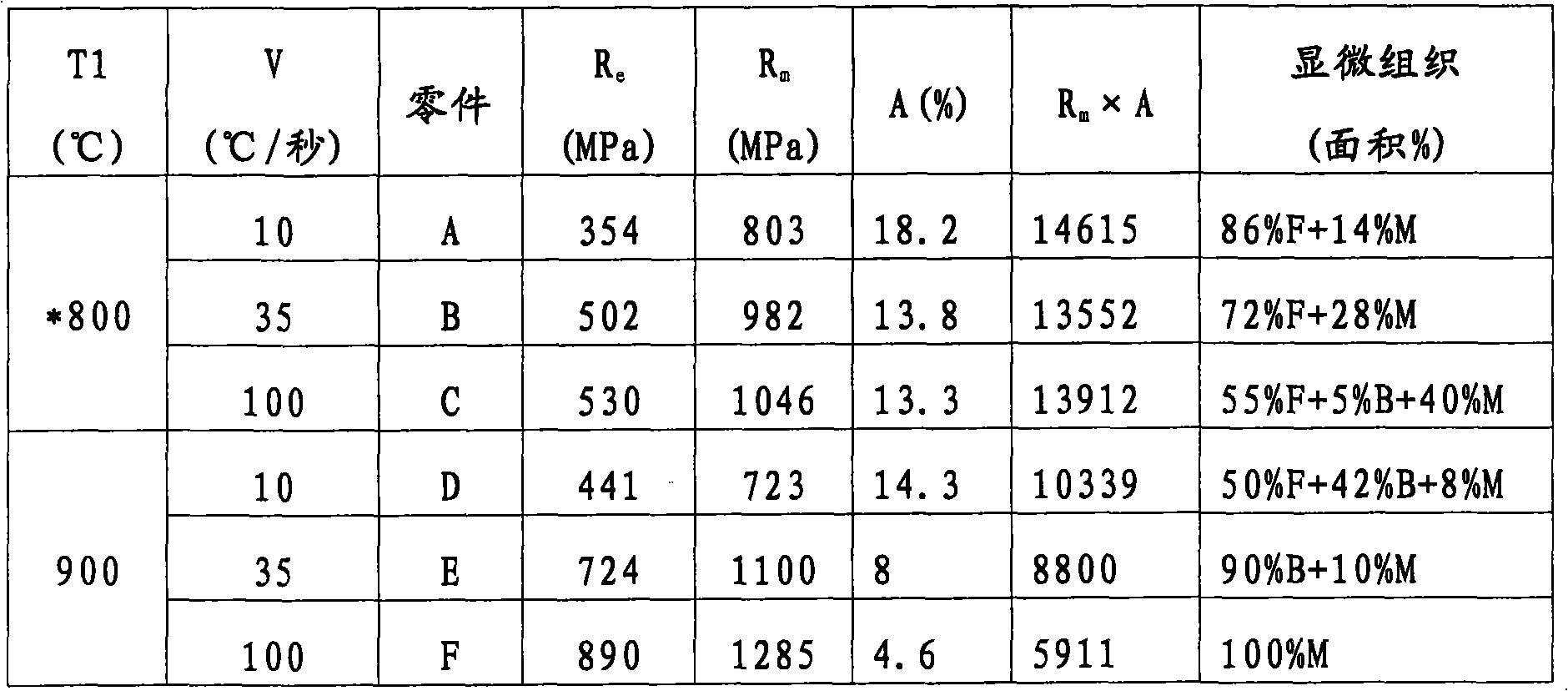

[0036] The method according to the invention consists in hot forming a blank previously cut from a steel strip, in a specific temperature range, to form a steel part, the composition of which is typically that of a steel with a multiphase microstructure, but which in It is not necessary to start with a multiphase structure, the steel part acquires a multiphase microstructure when it cools between the forming tools. The inventors have also demonstrated that a homogeneous multiphase microstructure can be obtained independent of the billet cooling rate between tools as long as the cooling rate is sufficient.

[0037] The advantage of the invention is that it is not necessary that the multiphase microstructure is formed already during the stage of manufacturing the hot-rolled sheet or its coating, but rather at the stage of manufacturing the part by hot forming, which makes it possible to ensure the final A multiphase microstructure is uniform in every region of the part. This is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com