Autoclaved aerated concrete slab collocated with rust resistant layer steel bar and concrete mortar

A technology of autoclaved air filling and concrete slabs, which is applied to floors, building components, buildings, etc. It can solve the problems that cannot be used as load-bearing parts, the specificity of prefabricated panels is large, and the weight of buildings is large, so as to achieve high durability and reinforcement. The effect of reducing the effect and reducing the construction cost

Inactive Publication Date: 2008-10-29

哈尔滨工业大学空间钢结构幕墙有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The proportion of the existing prefabricated panels is relatively large, resulting in a large building weight and high foundation cost

The specific gravity of air-entrained concrete is relatively small, but its strength is not good enough to be used as a load-bearing component

And for many years, people have been accustomed to using steel bars as tensile components. Since one of the main raw materials of air-entrained concrete is lime, steel bars are buried in air-entrained concrete, which will soon be corroded and brittle. Air concrete has always been available only as a non-load-bearing component

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

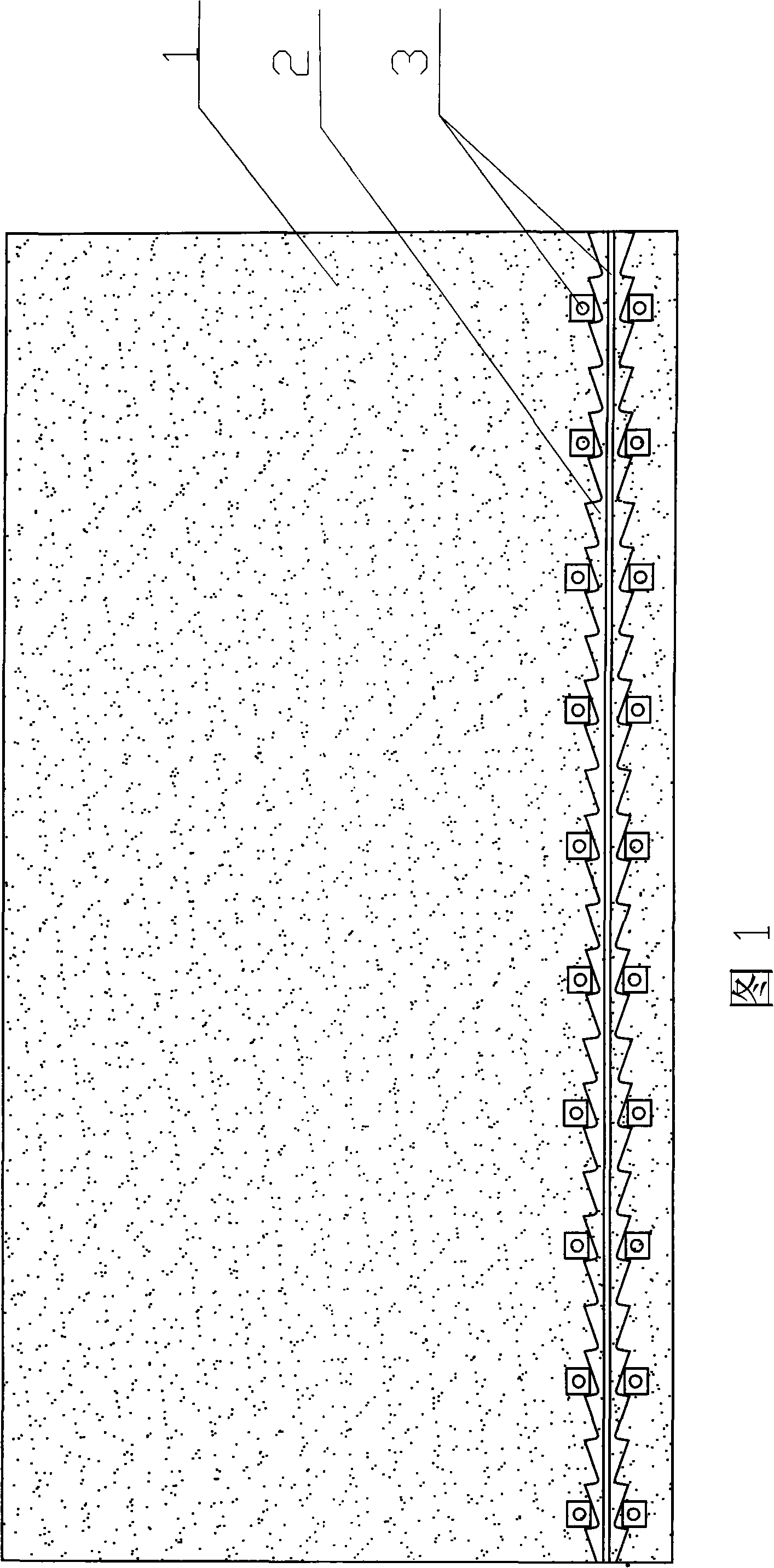

The invention relates to an autoclaved aerated concrete slab provided with cement mortar reinforced bars having rust prevention layers and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises building used concrete structural slabs, wherein the concrete is autoclaved aerated concrete (1), and the concrete in the structural slabs is provided with tension resistant strengthening ribs (3) containing carbon fibers (2). The product can be used as precast elements for buildings, such as floor slabs, roof slabs and wall slabs, etc.

Description

Autoclaved aerated concrete slab equipped with cement mortar antirust layer reinforcement Technical field: The invention relates to a building prefabricated board with antirust layer steel bars made of autoclaved aerated light concrete and its application as floor and roof boards. Background technique: The proportion of existing prefabricated panels is relatively large, resulting in a relatively large building weight and high foundation costs. The specific gravity of air-entrained concrete is relatively small, but its strength is not good enough to be used as a load-bearing component. And for many years, people have been accustomed to using steel bars as tensile components. Since one of the main raw materials of air-entrained concrete is lime, steel bars are buried in air-entrained concrete, which will soon be corroded and brittle. Air concrete has always been available only as a non-load-bearing component. Invention content: The purpose of the present invention is to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B5/02

Inventor 陈月明宋昌永魏震南

Owner 哈尔滨工业大学空间钢结构幕墙有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com