Gantry planning and milling transmission box

A gearbox, planing and milling technology, applied in the field of machinery, can solve the problems of complex DC control, high power consumption of the motor, and high cost, and achieve the effects of huge economic and social benefits, high power consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

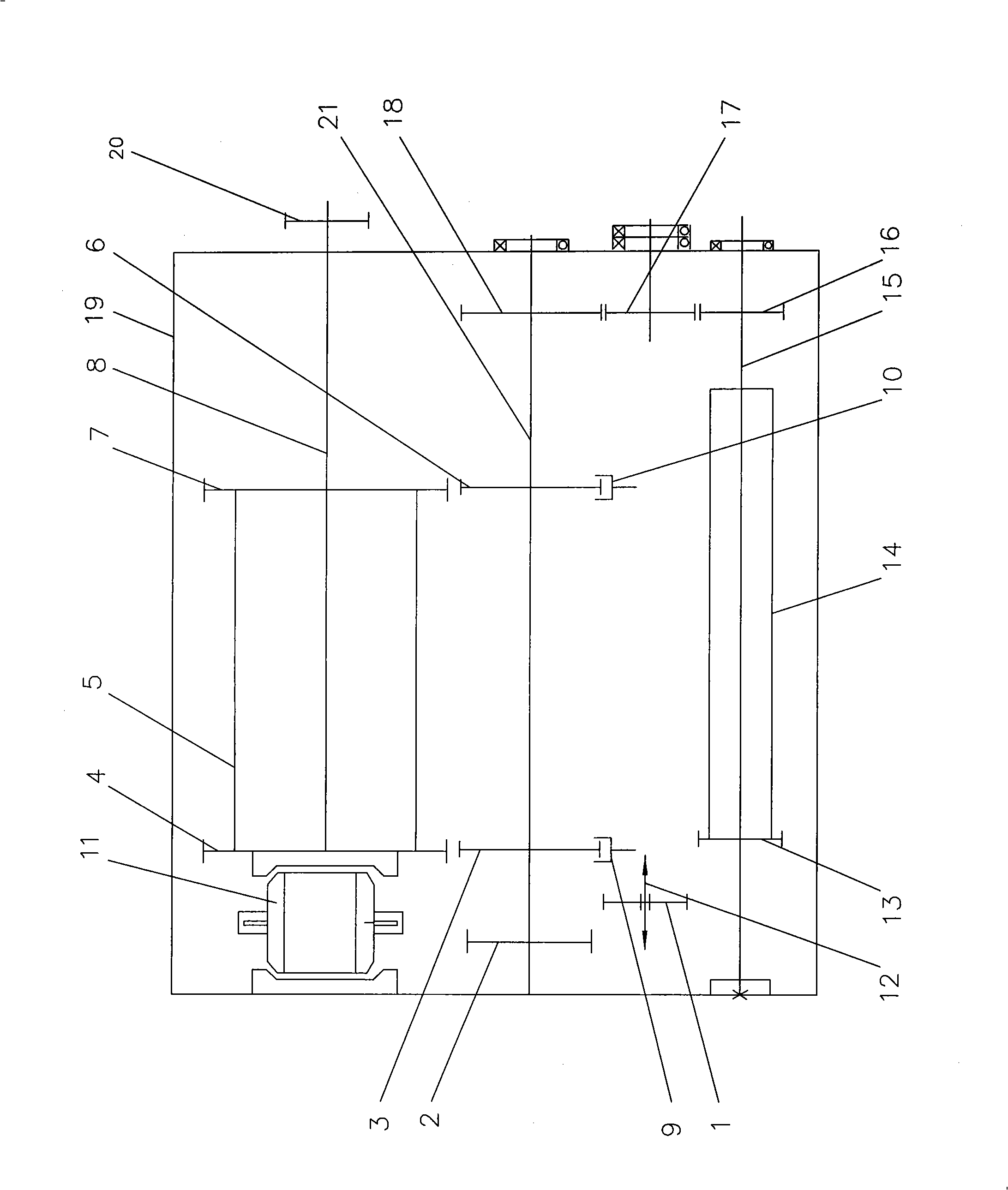

[0006] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0007] Provided by accompanying drawing, hydraulic non-stop clutch 11 is housed in casing 19 left sides of the present invention, hydraulic non-stop clutch 11 links to each other with differential speed reducer 5 through clutch gear 4, and the output shaft 8 of differential speed reducer 5 is in casing 19 The outer end of the planer is mounted on the coupling shaft of the planer power wheel 20, the differential speed reducer 5 is equipped with a transmission gear 7 on the output shaft 8 in the box body 19, and the transmission shaft 21 is sequentially equipped with the driven gear 2, the first A fork gear 3, a second fork wheel 6 and a rotating gear 18, the first fork gear 3 is connected with the first fork 9, the second fork wheel 6 is connected with the second fork 10, the first fork gear 3 is clutched with the clutch gear 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com