Preparation method and application of modified polyester masterbatch

A polyester and masterbatch technology, applied in the field of fiber manufacturing, can solve the problems of poor anion release in fabrics and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

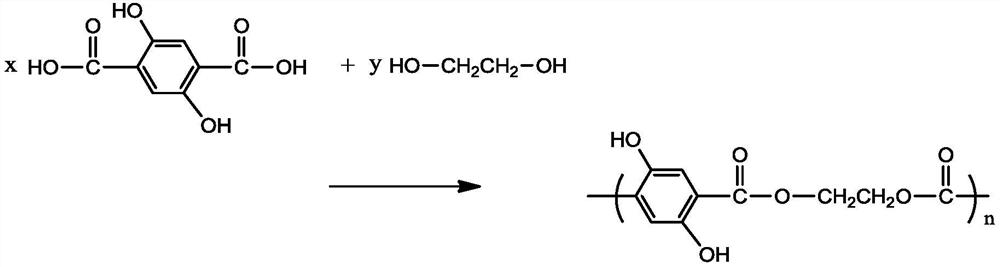

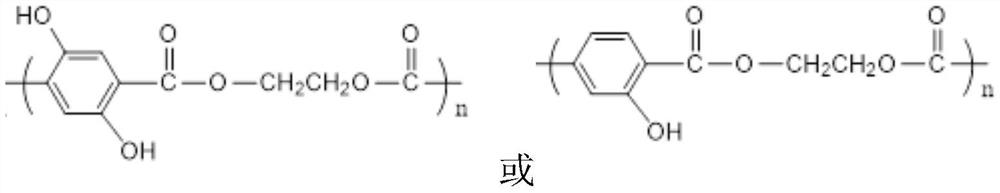

[0054] Mix 67.2 kilograms of tourmaline powder (120nm in particle size) with 62 kilograms of ethylene glycol (1000 moles), and stir at room temperature for 0.5 hour to fully infiltrate the negative ion powder. Then add 198.2 kilograms of 2,5-dihydroxyterephthalic acid (1000 moles), 83 grams of catalyst antimony trioxide, 220 grams of matting agent titanium dioxide, heat up to 80 ° C and stir for 1 hour to dissolve the catalyst, and then continue to heat up to React at 250°C, observe water, after 4 hours, the esterification rate reaches 90%, continue to heat up to 290°C for 5 hours, the melt viscosity reaches 0.58, stop the reaction, cool and cut into pellets, and prepare negative ion powder masterbatch wrapped in modified polyester . Its in-situ polymerization reaction formula is as follows:

[0055]

[0056] On the conventional polyester fiber production line, the negative ion powder masterbatch is added before the screw extruder through the color masterbatch adding devic...

Embodiment 2

[0058] Change the tourmaline powder add-on in embodiment 1 to be 85 kilograms, all the other material add-on and operation steps, process parameter are the same as embodiment 1. When the melt viscosity reaches 0.61, the reaction is terminated, cooled and pelletized, and the modified polyester-wrapped negative ion powder polyester masterbatch is obtained.

[0059] On the conventional polyester fiber production line, the negative ion powder polyester masterbatch is added before the screw extruder through the color masterbatch adding device, the addition amount is 15% (weight ratio) of the conventional polyester feed amount, and the spinning speed is 3300 meters. The temperature was 285°C. Negative oxygen ion polyester fibers were obtained, and the measured negative ion release was 5200 / cm 3 .

Embodiment 3

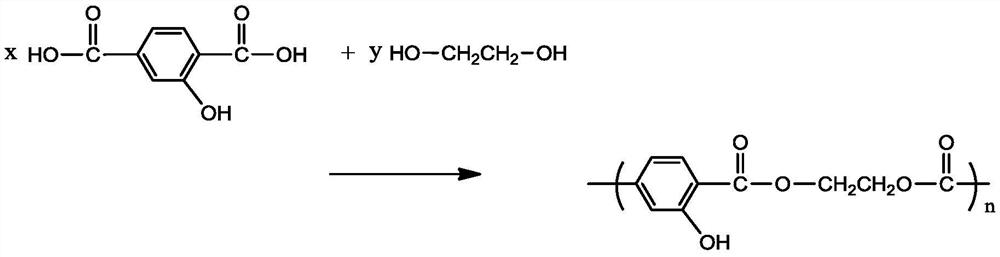

[0061] Mix 67.2 kilograms of tourmaline powder (120nm in particle size) with 62 kilograms of ethylene glycol (1000 moles), and stir at room temperature for 0.5 hour to fully infiltrate the negative ion powder. Then add 182 kilograms of 2,5-dihydroxyterephthalic acid (1000 moles), 83 grams of catalyst antimony trioxide, 220 grams of matting agent titanium dioxide, heat up to 85 ° C and stir for 1 hour to dissolve the catalyst, and then continue to heat up to React at 250°C, observe the water, after 3 hours, the esterification rate reaches 90%, continue to heat up to 290°C for 5 hours, the melt viscosity reaches 0.55, stop the reaction, cool and cut into pellets, and obtain a modified polyester-wrapped anion powder polyester masterbatch grain. Its in-situ polymerization reaction formula is as follows:

[0062]

[0063] The spinning process is the same as in Example 1, and the negative oxygen ion polyester fiber obtained by spinning has a measured negative ion release of 3700...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com