Alarming method and device for preventing drilling rod-dropping accident of rotary digging drill rig

A technology for rotary drilling rigs and drill pipes, which is applied in the direction of rotary drilling rigs, drilling equipment and methods, alarms, etc., which can solve the problems of being unknown and not having the function of safety protection, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

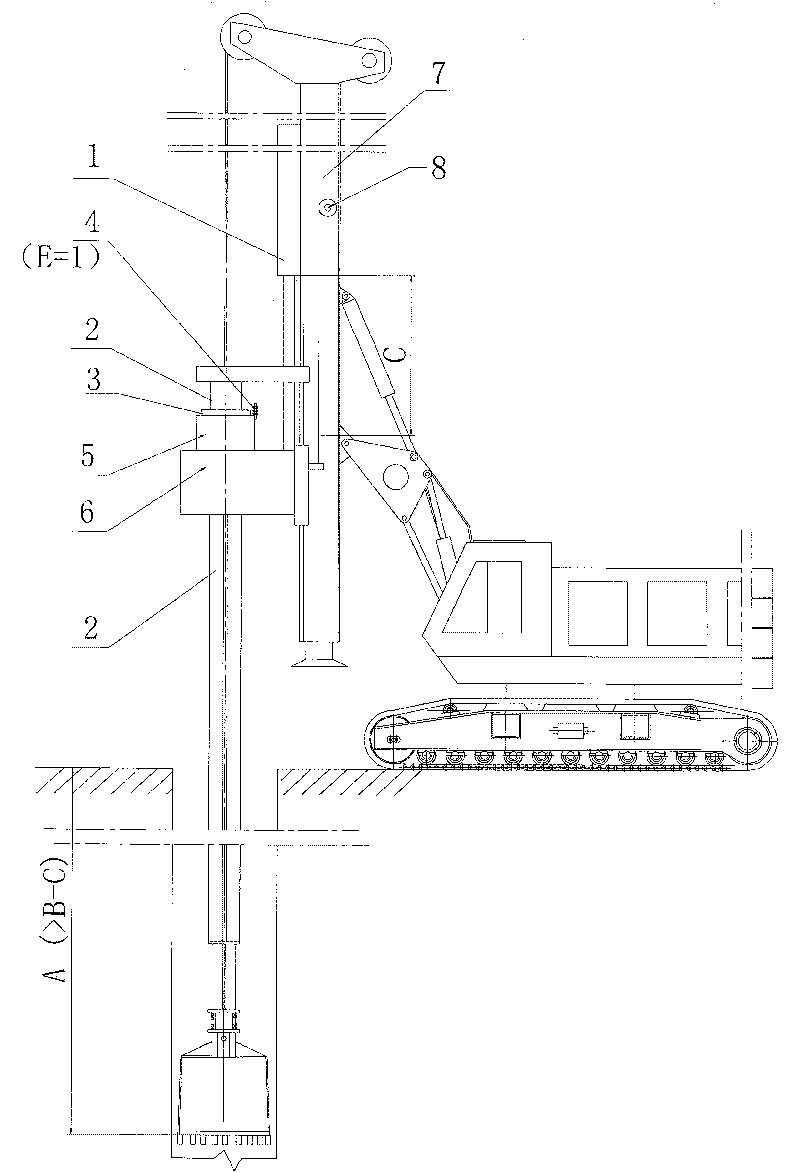

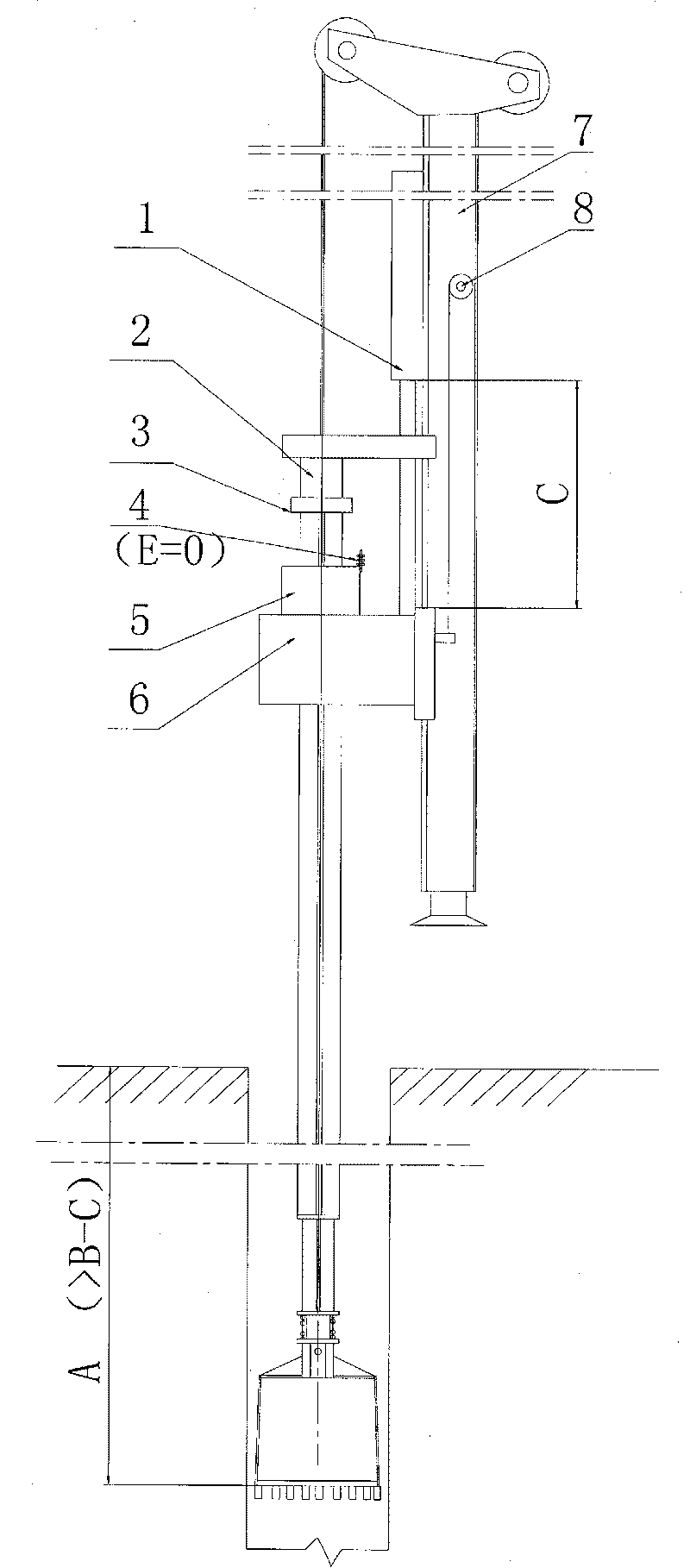

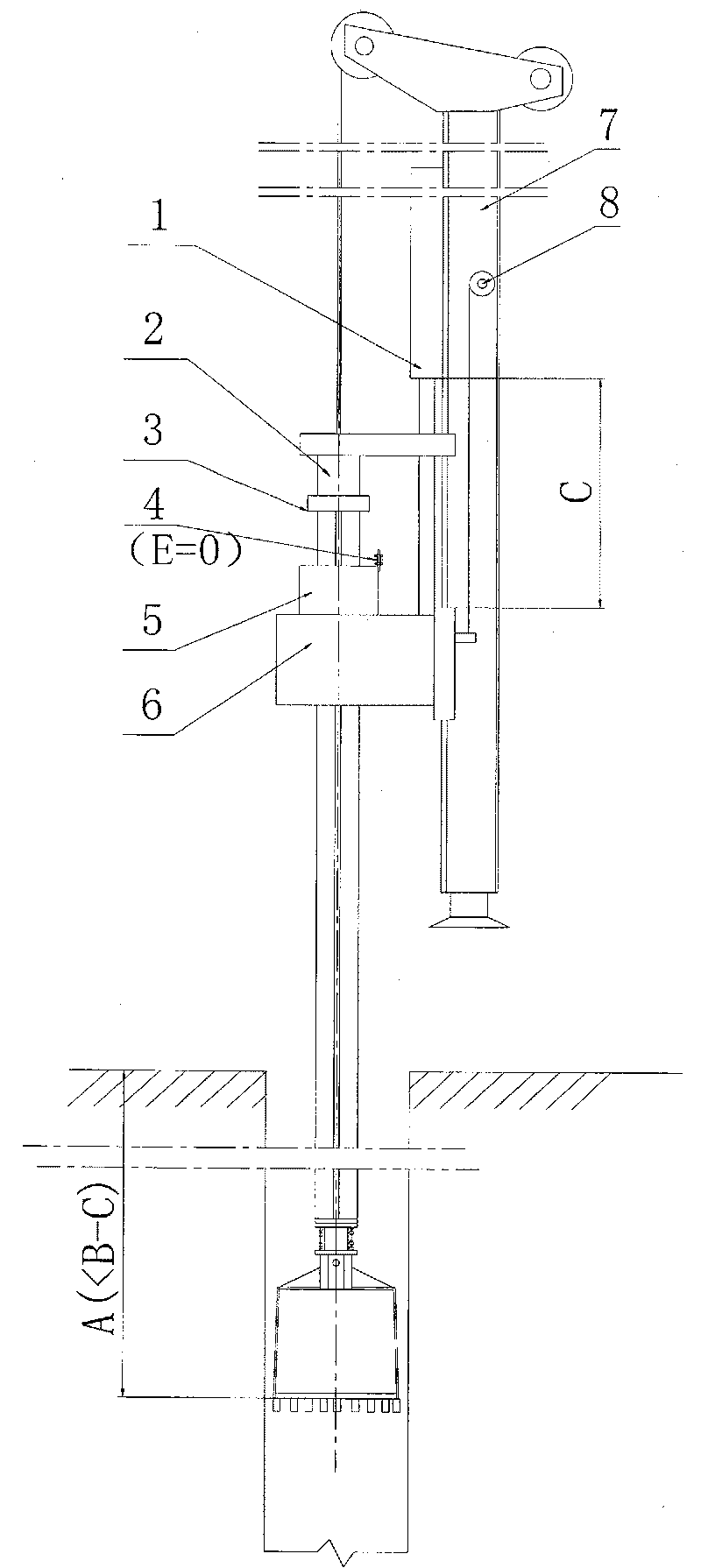

[0022] The alarm method to prevent the accident of the rotary drilling rig from dropping the drill pipe is to install the detection probe 4 above the buffer 5 of the rotary drilling rig, and when the upper flange 3 of the drill pipe of the rotary drilling rig falls on the buffer 5 of the power head, it will enter the detection In the sensing area of the probe 4, the detection probe 4 inputs the sensed relationship data signal E between the drill pipe and the power head to the microprocessor. The signal is "E=0"; a displacement sensor 8 is installed on the drill mast 7 of the rotary drilling rig to detect the relative displacement of the power head 6 of the rotary drilling rig from the top dead center downward, and the detected power head The displacement data C of the rotary drilling rig is input to the microprocessor; the current depth data A of the drill bucket of the rotary drilling rig is input to the microprocessor through the interface circuit 9 of the depth of the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com