Electric motor with fixing adapter

A technology of adapters and motors, applied in the field of motors, can solve problems such as high structural matching costs, and achieve the effect of strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

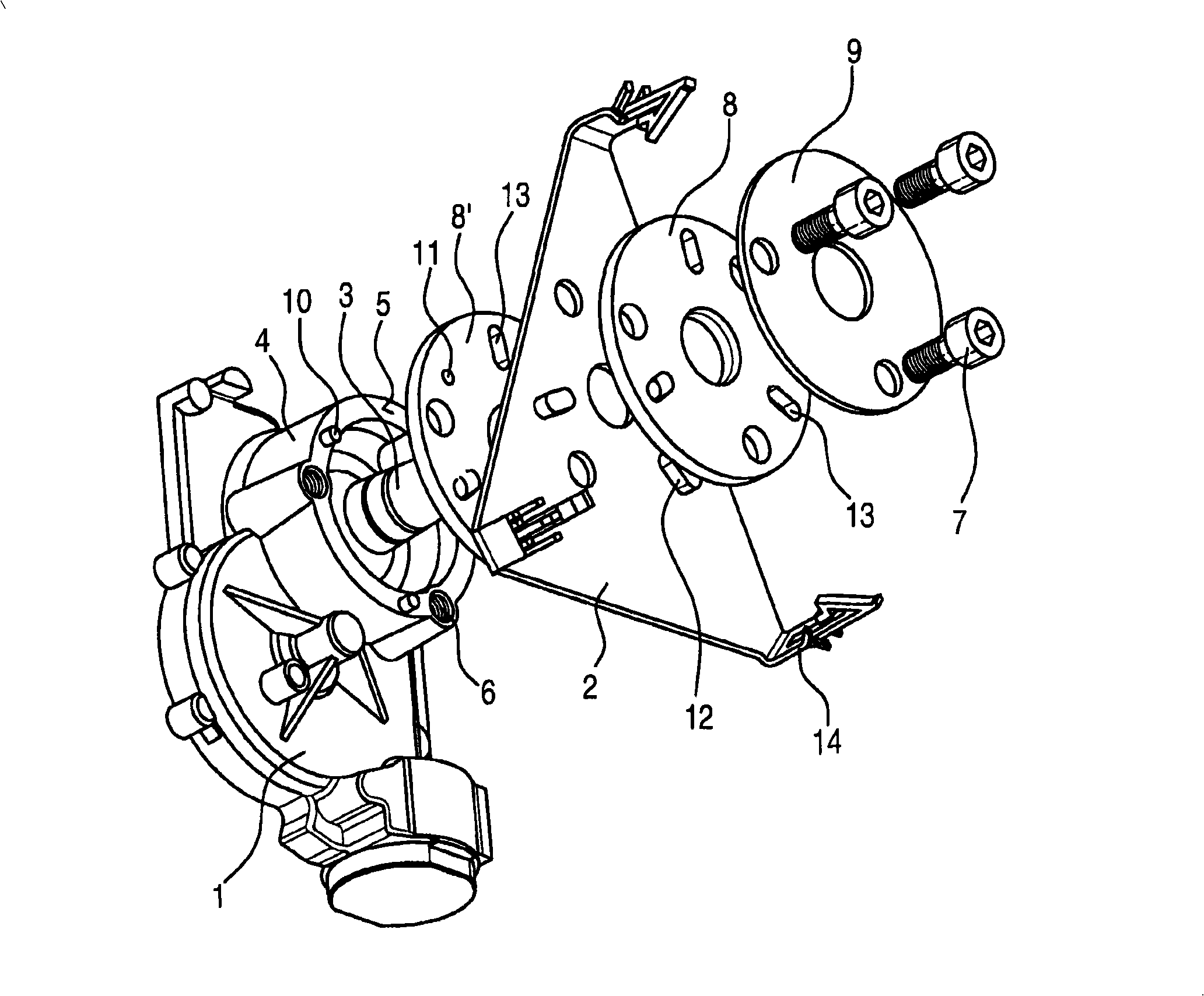

[0028] figure 1 An exploded view of the arrangement according to the invention with the rear windscreen wiper motor in the housing 1 and the fastening adapter 2 is shown. The drive shaft 3 can be seen, which is surrounded by a support structure 4 which is fixedly connected to the housing 1 and thus also to the electric motor. The support structure 4 is designed as a cylinder with a flat support surface 5 surrounding the housing region of the drive shaft 3 of the wiper device. A threaded hole 6 is inserted into this support surface 5 , into which a screw 7 for fastening the fastening adapter 2 to the housing 1 of the rear windshield wiper motor can be inserted. The fastening adapter 2 itself is designed as a steel component, which is formed by deep drawing. In the present exemplary embodiment, the fastening adapter is largely designed in the shape of a flat surface. However, other geometries can be produced without problems by deep drawing, so that different installation spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com