Automatic regulation granulating mechanism

An automatic adjustment and granulation technology, applied in the field of granulation mechanism, can solve the problems of difficult manufacturing, difficult implementation, excessive contact force of cutter, etc., and achieve the effect of good product quality, easy maintenance and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

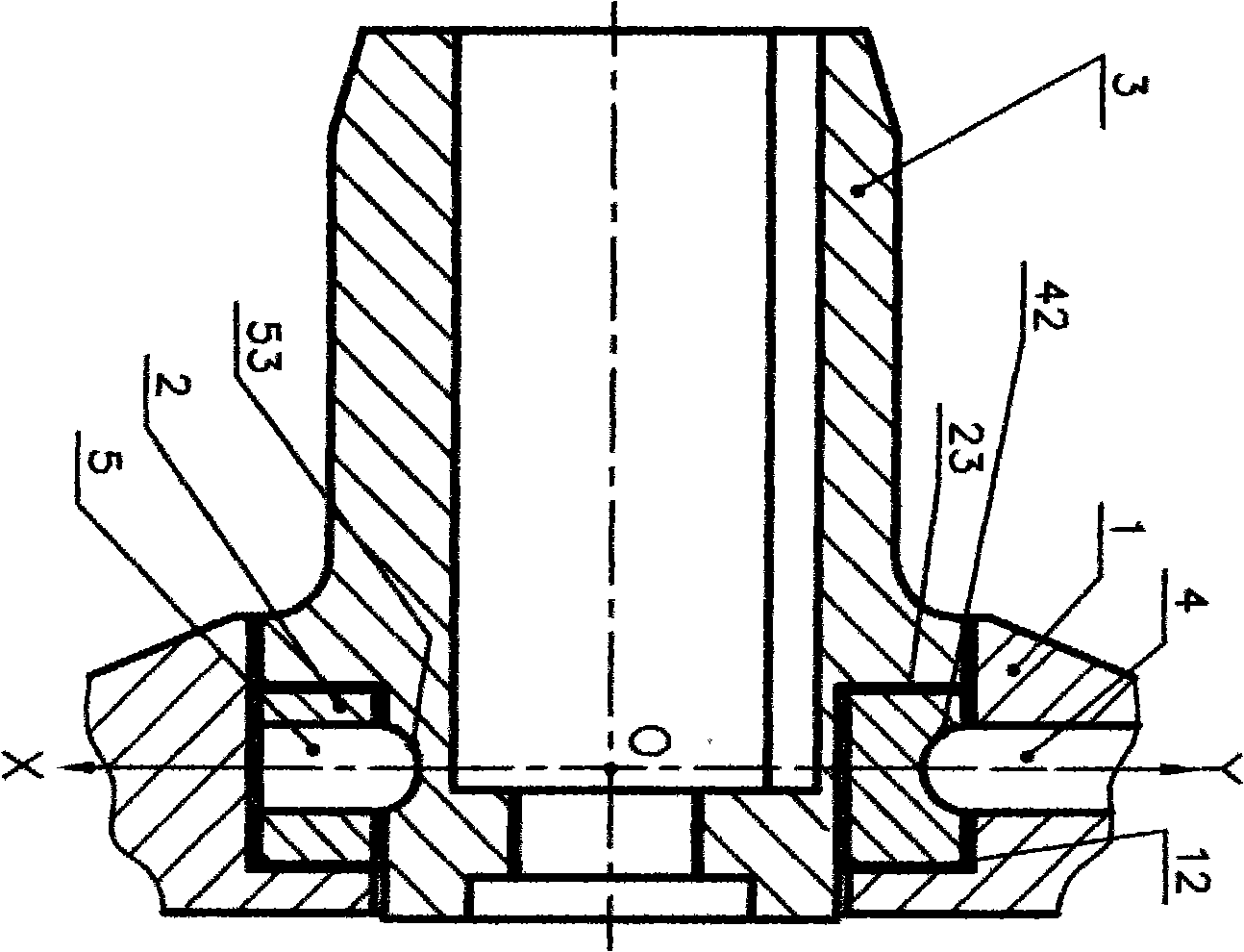

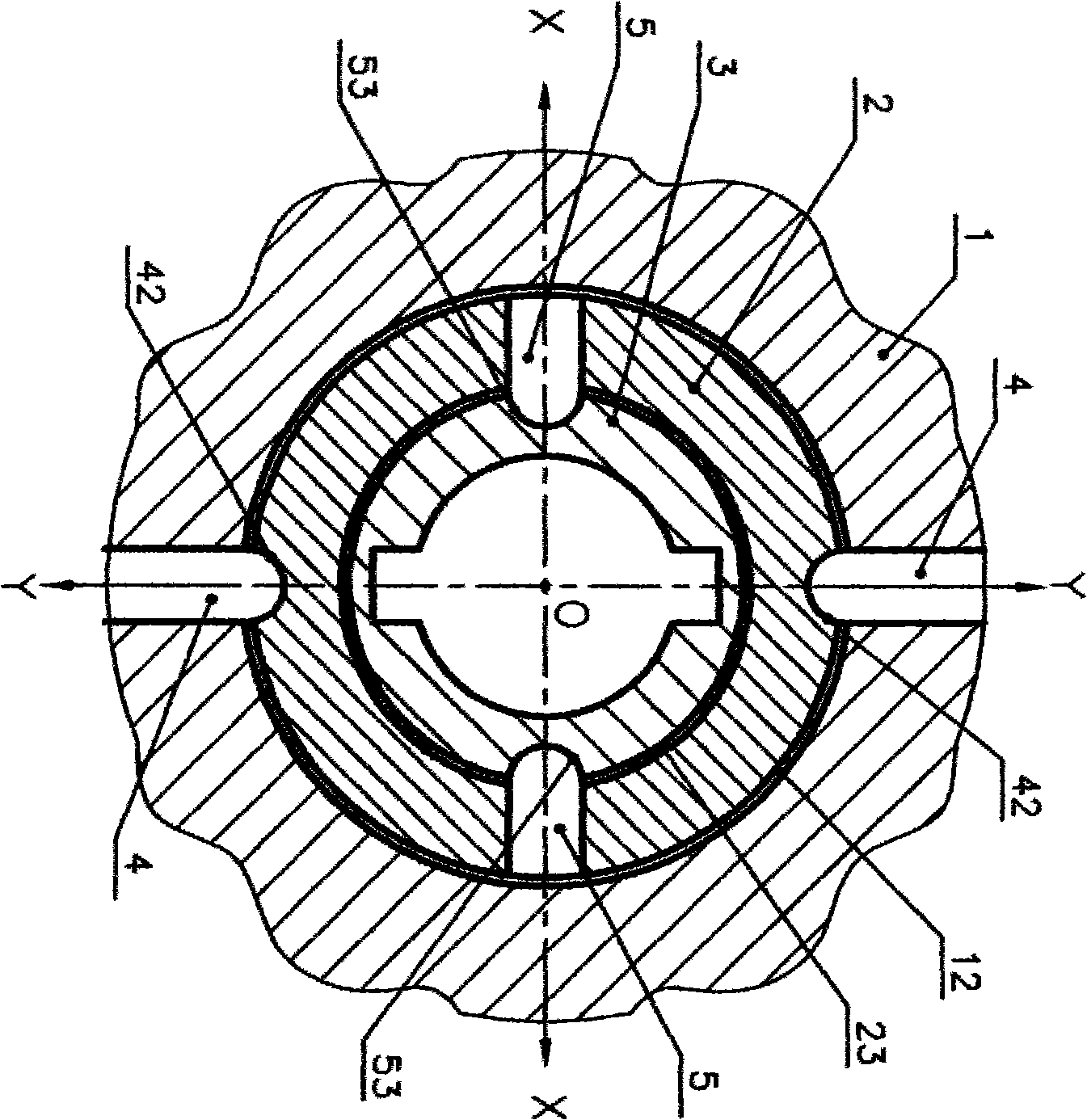

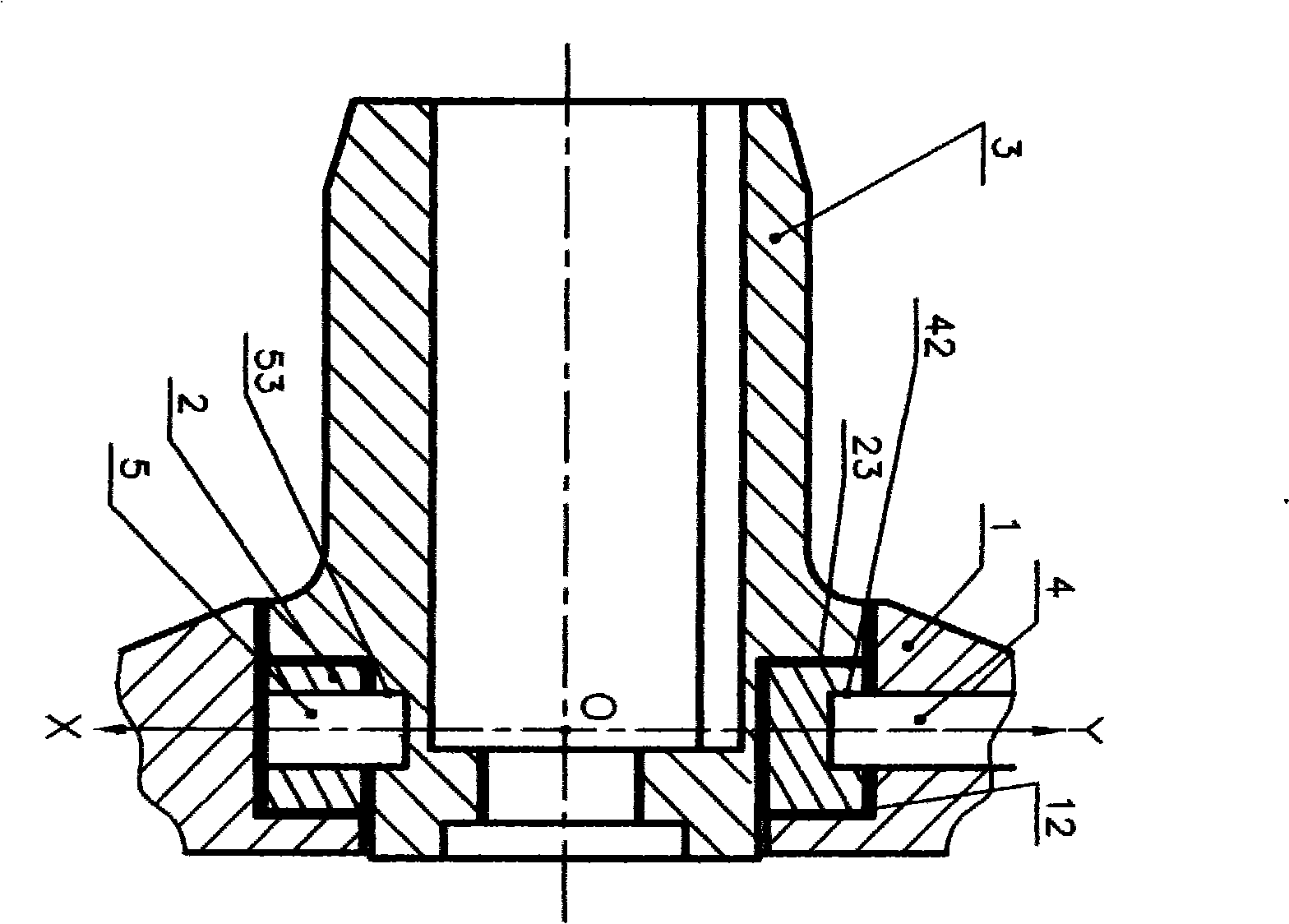

[0023] refer to Figure 1 to Figure 5 .

[0024] The present invention provides an automatic adjustment granulation mechanism that achieves approximately the same contact pressure between the cutters 8 and the template 7 during granulation.

[0025] The object of the present invention is accomplished in the following manner:

[0026] An automatic adjustment granulation mechanism, including a knife holder 1, a swing ring 2, and a shaft sleeve 3; the knife holder 1 and the swing ring 2 are connected through two external torque transmission rods 4, and the swing ring 2 and the shaft sleeve 3 The torque transmission rod 5 is connected; there is a side gap 12 between the tool holder 1 and the swing ring 2, and a side gap 23 between the swing ring 2 and the bushing 3; multiple cutting knives 8 are installed on the knife holder 1; two external torque transmission rods 4. The outer end is fixedly connected to the tool rest 1; the outer ends of the two inner torque transmission rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com