Combined type rotating machinery combined failure diagnose test apparatus

A technology for rotating machinery and composite failures, applied in the testing of mechanical components, measuring devices, and testing of machine/structural components, etc., can solve problems such as damage and aging of disassembled and assembled machines, difficult combination of composite failures, and limited types of failures. Simple, easy to operate, convenient to analyze the effect of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

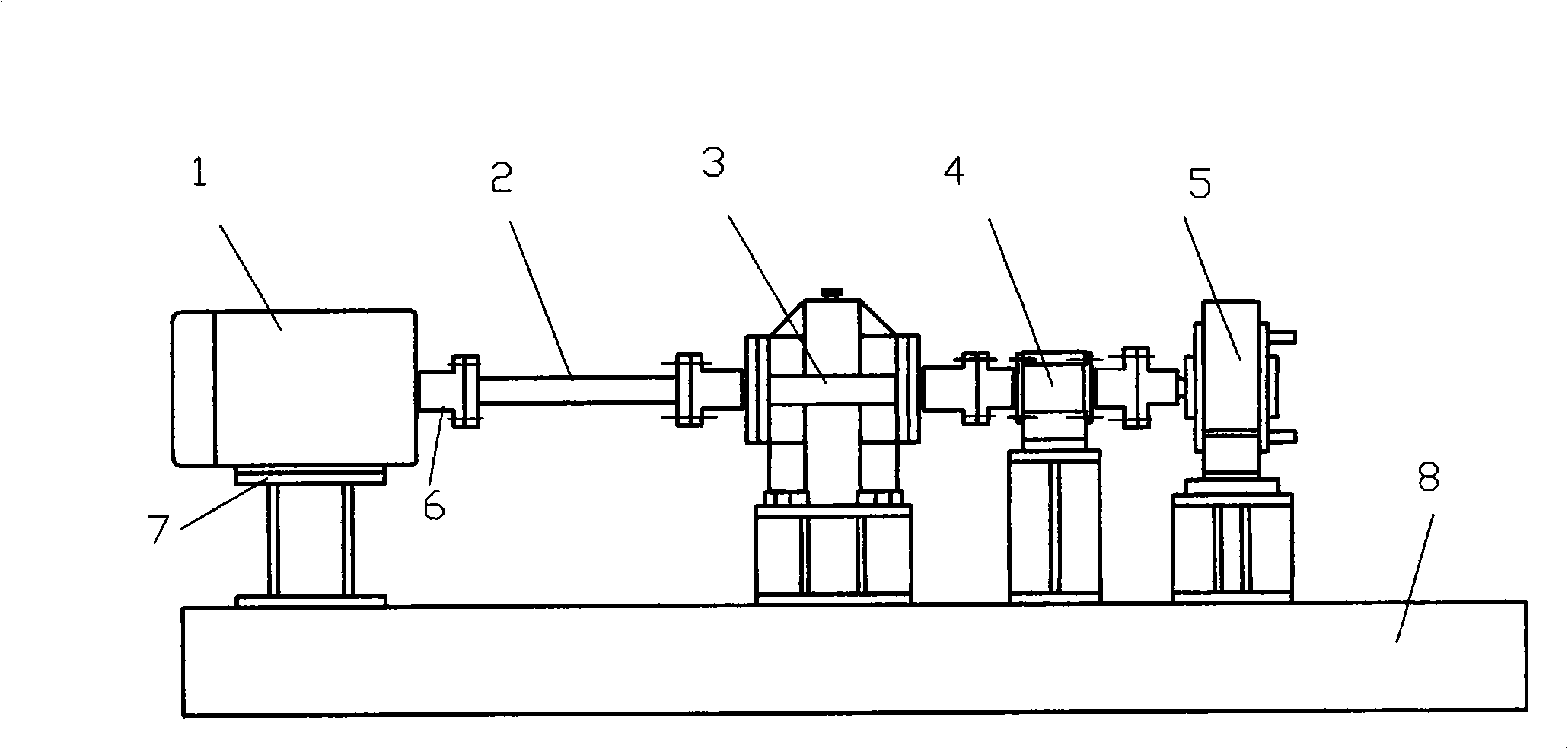

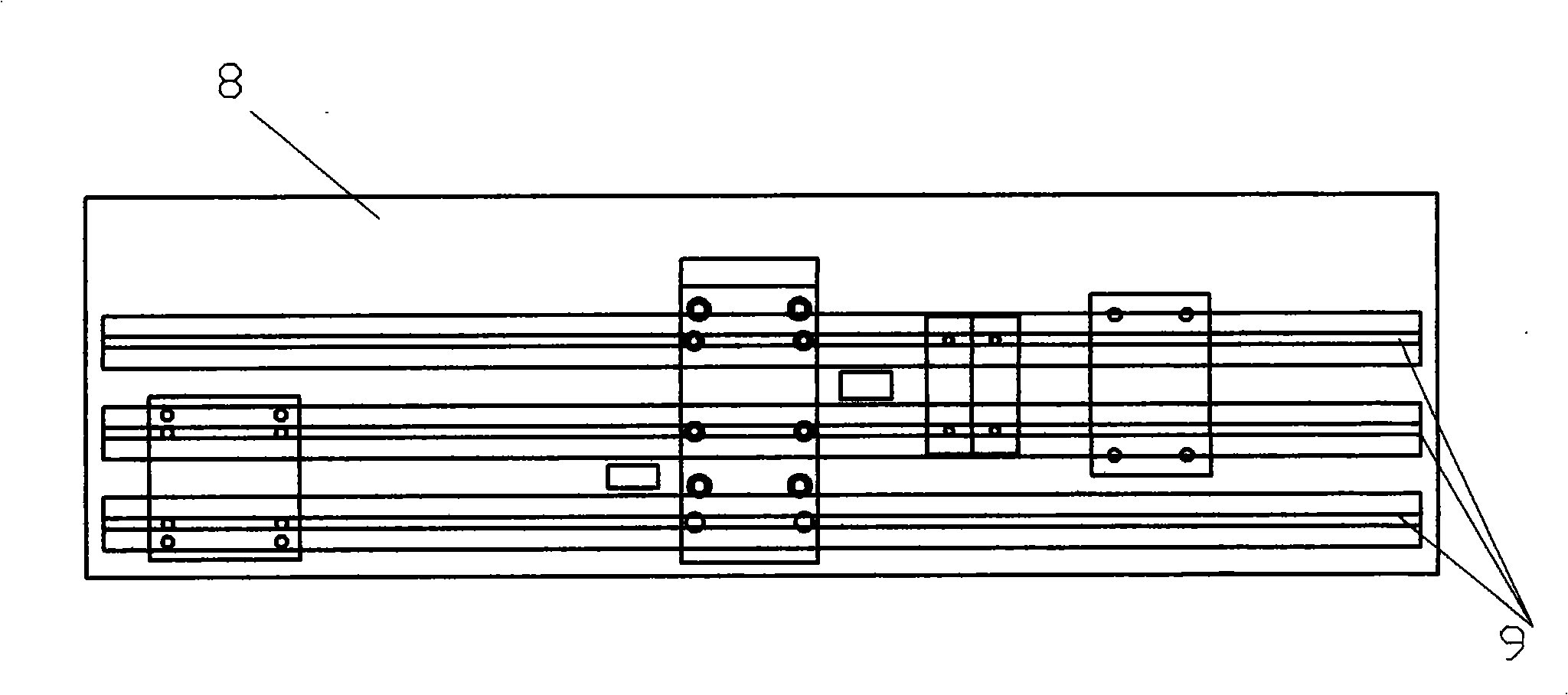

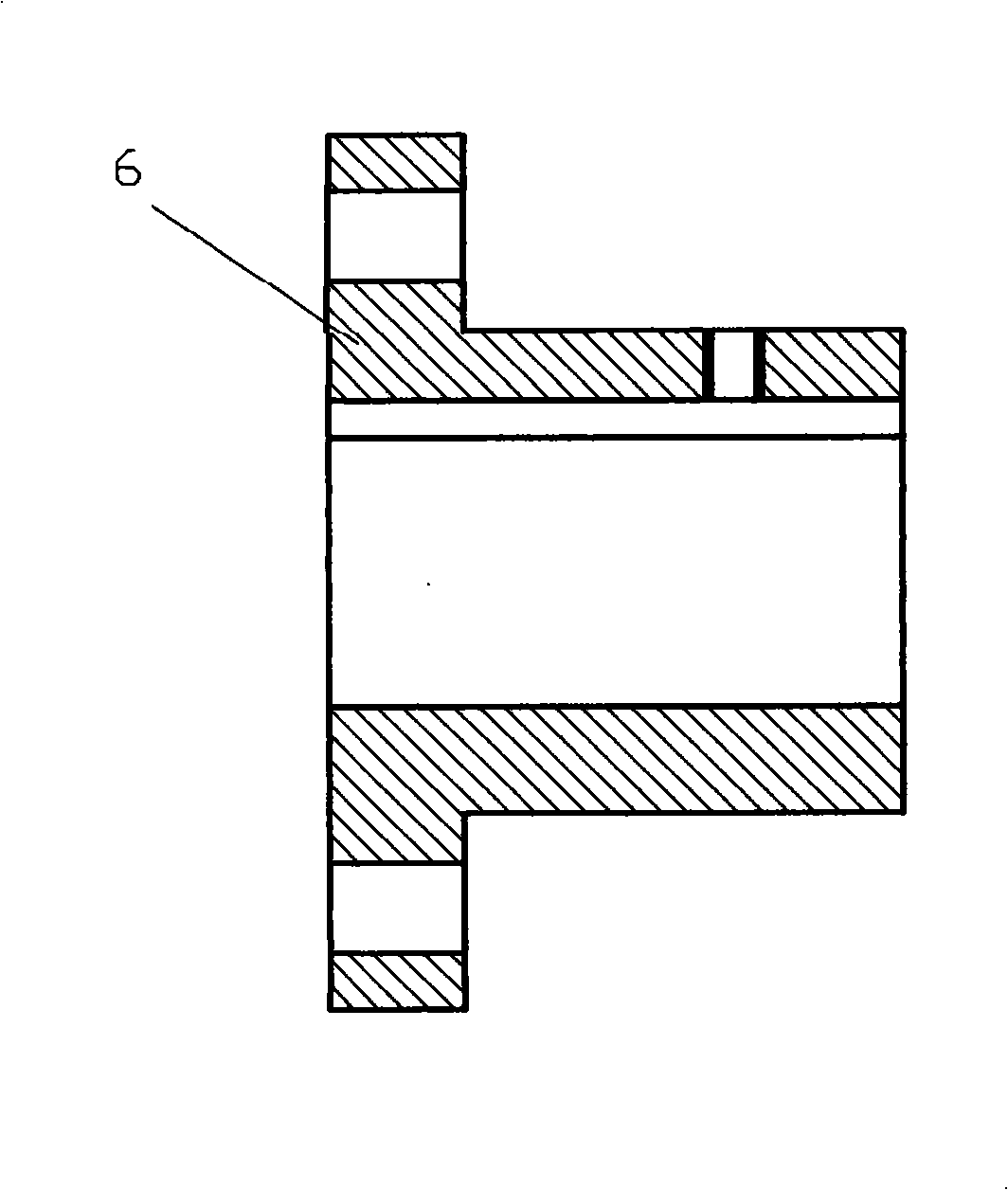

[0015] exist figure 1 , figure 2 Among them, the surface of the base 8 is provided with three T-shaped slots 9 arranged in parallel and having the same size and shape, and several mutually independent supports 7 are installed on the base 8 through the T-shaped slots 9. The T-shaped groove 9 has matching holes, which can be fixed with movable nuts. The motor 1 and the devices driven by the motor 1 are fixed on the bracket 7, and various faults can be combined by the bracket 7 moving in the T-shaped slot. The devices include the test shaft 2, the gear box 3, and the test bearing seat 4. and load 5. The motor 1 is connected to the test shaft 2, and the test shaft 2 is connected to the gearbox 3 through a coupling, and then connected to the transition bearing seat and the load in sequence according to the above connection method.

[0016] The test shaft 2 includes normal shaft, misaligned shaft, eccentric shaft, bent shaft and cracked shaft.

[0017] The gearbox 3 includes no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com